Energy costs keep rising and, depending on who you talk to, we’re either heading toward a recession or are already there. The advice for businesses varies: raise rates, hold off on raising rates until you reach some kind of threshold or don’t raise rates at all but look for other areas where you can save money.

Energy costs keep rising and, depending on who you talk to, we’re either heading toward a recession or are already there. The advice for businesses varies: raise rates, hold off on raising rates until you reach some kind of threshold or don’t raise rates at all but look for other areas where you can save money.

In the current supply and demand situation for collision repairers, the best advice might be to streamline operations and look for ways to gain additional efficiencies.

Body shops in general can be classified as high energy users relative to the size of the business, and when this elevated energy cost is combined with low net profits, the impact of rising fuel and electricity costs is a burden many shops will struggle with. It’s estimated that natural gas has increased by over 40 percent in the last three years, and electricity has increased by a similar amount. More worrying is that the trend is expected to continue.

One way to curb these costs is to choose the most energy-efficient spraybooth possible. Many different kinds of spraybooths such as the following tout

energy-saving features.

AFC Finishing Systems

- AFC uses energy efficient/ inverter-duty, open-type drip-proof motors that carry the EE symbol (meet or exceed EPACT Efficiency Standards).

- AFC’s fan design (tube-axial, efficient fan blades, etc.) provides target airflow (CFM) with relatively low horsepower motors.

- AFC uses Quicktronic series instant start light ballasts, which provide good lamp life and the best possible energy efficiency. They operate Sylvania Octron T8 lamps with maximum efficiency and high lumen output, which provide a 30 percent to 40 percent energy savings relative to F40T12 magnetic systems.

- AFC offers Variable Frequency Drives (VFDs) which ramp up exhaust fans for filter loading. This will reduce the amp draw when the filters are new.

- AFC uses direct-fired burners (no heat exchangers). Approximately 100 percent of the heated air is used to heat the booth.

- AFC’s exclusive “superheating” cure technology allows partially heated air to recirculate past the burner a number of times before entering the spraybooth cabin, resulting in fast temperature rise and lower energy costs.

- AFC control panels meet the newest UL508a code. This code was designed for industrial control panels and has strict requirements on efficiency and component life.

Web site: www.afc-ca.com

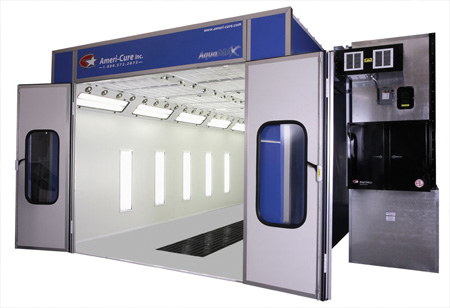

Ameri-Cure

The AquaMAX Spray Booth and Energy Miser is the solution for highest energy efficiency and ultra clean paint jobs. Get radically decreased flash times while dramatically increasing production speed. The MAX60 multi-directional nozzle system offers flexibility no matter what portion of or what vehicles are being painted.

The Igloo Energy Management System provides supreme energy efficiency controlled by the Climate- Right Touch Screen Control Panel.

Phone: (800) 572-2873

Web site: www.ameri-cure.com

Blowtherm

Blowtherm North America is currently offering as a standard feature on all “Extra Series” models a new design for their direct fired burner where the unit has the capability to recirculate the already heated air in the cure cycle. This new process allows for greater natural gas savings and cleaner air during the cure cycle. The design has been used in Europe for several years.

Web site: www.blowtherm.com

Garmat USA

Garmat USA is committed to incorporating principles of environmentally-conscious design and energy efficiency into all of its refinish equipment. The result is an optimal balance of cost, environmental, societal and individual benefits while meeting the mission and function of the intended equipment.

AcceleCure: The Accele-Cure System draws air towards the center of the booth and accelerates the air delivered from the plenum, which concentrates air movement over the vehicle for faster flashing and curing. Overall cycle time and energy costs are dramatically reduced.

Quik-Cure: Quik-Cure utilizes a multi-stage timer that enables different settings for a “quick-cure” of the vehicle, depending on paint manufacturer requirements. It shortens bake cycle times.

Energy conservation unit: When in the spray mode and the spray gun is not activated, the Energy Conservation Unit recycles 80 percent of the heated air in the booth (100 percent in CTOF), reducing energy costs.

Variable Frequency Drive: Garmat utilizes VFDs for smooth motor startup and optimum air management. By controlling the speed of the motors, VFDs provide significant energy savings.

Touch-screen controller: An interactive panel offers control of the booth with a touch of the screen. The touch screen allows for the maintaining of ideal pressures for spraying and curing cycles, utilizing only the amount of energy necessary.

High-efficiency reflective lighting: Garmat USA utilizes color-corrected fluorescent bulbs. Optional reflectors are available to achieve more efficient illumination without the added utility costs.

Phone: (800) 442-7628

Web site: www.garmat.com

Global Finishing Solutions

Each piece of a paint booth that draws power or uses fuel needs to be chosen carefully in order to provide the maximum level of energy savings. That’s why GFS only uses the most efficient parts possible in the construction of its ECO paint booths.

The lights in GFS booths are equipped with T-8 low-mercury color-corrected tubes and energy-saving ballasts. The booths also feature VFDs to provide unparalleled control over the booth motors for superior energy savings, as well as high-efficiency direct-fire burners for maximum heat transfer. Programmable control panels ensure the booths operate for the least amount of time per job, consuming the least amount of gas and energy. GFS’s AdvanceCure system enhances the airflow in the booth to create a more effective drying environment, minimizing the time required to finish each job. Energy savings comes from a complete set of high-efficiency components found in every GFS ECO paint booth.

SmartCure accelerated curing system reduces cure times up to 50 percent. A Soft-Start Energy Saver eliminates power spikes when the heat system is operating and automatically switches to “economy mode” when the operator in the booth has stopped spraying, resulting in cost savings of up to 60 percent in power usage and up to 75 percent in fuel. Direct-drive motors offer more efficient performance.

Web site: www.globalfinishing.com

Junair

A Junair 4 Series spraybooth’s QADs auxiliary air movement system, 4-step variable speed drives/air flow and Fuel Saver (FS) automatic air recirculation system decrease energy costs by as much as 70 percent compared with a conventional booth. Direct gas firing, energy-efficient motors and high performance fans with energy-saving T5 fluorescent tubes reduce spraybooth operating costs even further.

The new 4-Series downdraft combination spraybooth oven incorporates a whole range of features and offers a body shop substantial reductions in energy consumption and related costs, reduced booth cycle times and an improved working environment. Junair estimates shops are gaining 15 minutes on every job on base coat alone.

Another feature is a full length, full width ceiling input filter. The extra width is made possible by a lighting system that takes up minimal ceiling area. The wider filter provides enhanced downdraft air movement. Overspray is dispersed faster, and mist clearance times are reduced by up to 50 percent compared to spraybooths with standard-sized ceiling filters. When specified with the EVAC fully gridded, fully extracted floor, the spraybooth improves airflow and reduces overspray.

A new purpose-designed Ultralux system features a modern, slim-line profile, energy efficient T5 fluorescent tubes and high frequency electronic components that combine to reduce energy costs.

Lighting levels of up to 1500 lux are consistently achieved, even when measured low down in the booth. Easy access is provided to the lighting, and inexpensive replacement tubes keep maintenance costs low.

The QADs system supplies additional airflow from the corners of the spraybooth cabin, reducing cycle times by 35 percent. The clean, filtered and heated air provides the ideal environment for the fast, controlled flash-off of waterborne base coats and the rapid through-curing of low VOC top coats. Savings in process times are reflected in substantial savings on energy costs – amounting to thousands of dollars throughout the lifetime of the spraybooth.

Phone: (866) 358 6247

Web site: www.junairspraybooths.com

Marathon

The side downdraft spraybooth is designed so the air enters through the intake filters in the ceiling, enveloping the vehicle with clean-filtered air at high velocities. Over-spray from the painting process is then pulled away from the vehicle and operator, then captured in the exhaust filters located on both sides of the spraybooth. The spray and cure heater package combined with Marathon’s new higher powered QADS system results in much faster cure times for greater energy savings.

Phone: (800) 919-9035

Web site: www.marathonfinishing.com

SAIMA North America

The accudraft spraybooths are engineered from the ground up using energy efficient components. Starting from the solid construction of the cabin down to the motors, they’re constructed with energy efficiency in mind. All booths come standard with T8 high-efficiency fluorescent fixtures and bulbs, premium efficiency TEFC motors and an I-Pad Intelligent Command Panel to control all of the functions that will lead to energy savings.

As an option on new booths or as a retrofit to old booths, accudraft offers AccuHertz VFDs. Coupled with the I-Pad controls, the VFDs save customers unnecessary energy spikes and allow painters to go into a “stand-by” energy saving mode while painting. This feature alone reduces the user’s energy costs by up to 40 percent.

Accudraft will soon be launching the AccuQADS Turbulent Air System that will reduce customers’ energy costs even further. This nozzle-based system supplies additional turbulent air flow from the corners of the spraybooth. More airflow means faster drying times. So this new product drastically cuts down cycle time in both solvent and waterborne applications and can reduce customers’ energy costs up to 40 percent as well.

Web site: www.saimanorthamerica.com

USI

Thanks to Chronotech technology, these real benefits can be achieved:

- Virtually 97 percent combustion efficiency.

- More efficient gas consumption (up to 30 percent less than typical Heat Exchanger indirect fired burner).

- Reaches desired set temperature quickly.

- High painting and baking temperature stability.

- Time reducing for reaching the baking temperature.

- Time reducing for the painting/baking phase (up to 35 percent).

- Up to a 45 percent reduction in electricity consumption by automatic variation of motor rotation speed and consequently of air volume, suiting them to the specific needs of the various work phases.

- Pre-programmed quantity of air recirculation during the baking phase is made possible through reduction in exhaust fan speed.

- Motors with Soft Start function that eliminates peaking at start-up.

- Software for pressure self-adjustment inside the spraybooth as filters become clogged.

Web site: www.usiitalia.com