I had driven by this particular body shop numerous times. They had added an attention-getting electronic sign out front, and I remembered their big building when it was the Case/IH farm implement dealership. From the sparkling glass on their front doors to the prompt greeting from the receptionist to the nice customer waiting area with the hooray-for-me wall of training certificates, they looked to be my poster child for how to make a good first impression in collision repair. Then I saw the one sign that’s a universal indicator of a truly great body shop: I-CAR Gold Class.

I had driven by this particular body shop numerous times. They had added an attention-getting electronic sign out front, and I remembered their big building when it was the Case/IH farm implement dealership. From the sparkling glass on their front doors to the prompt greeting from the receptionist to the nice customer waiting area with the hooray-for-me wall of training certificates, they looked to be my poster child for how to make a good first impression in collision repair. Then I saw the one sign that’s a universal indicator of a truly great body shop: I-CAR Gold Class.

Starting Out

Julie and Bruce Steinberg started North Iowa Collision Center in Clear Lake, Iowa, in 1999. They were both Iowans, but neither was from Clear Lake. They were looking for a town they liked with a building that suited them and found the right town thanks to the business development person from the Chamber of Commerce. However, they couldn’t find the right building. So unlike most start-up body shops that repurpose another building, they built their own 75’ x 100’ brand-new body shop.

Bruce had worked as a combo tech at a GM dealer before they began down the road of becoming entrepreneurs, and Julie had held various office management positions.

They opened the doors with two owners and a painter. Thanks to great customer service, they grew at over 15 percent every year, added employees and outgrew their 7,500-square-foot building. They also needed a new baking downdraft booth to keep pace in the paint shop. They calculated that installing it within their existing space would disrupt production for four to six weeks, and they couldn’t make that work, so they investigated adding on space to the building. But they still wouldn’t have the room for other things the shop needed, such as a drive-in estimating bay, a nice lobby and waiting area, space to repair semis and RVs (work they were turning away daily), an employee break room, efficient parts room and more.

Moving and Expanding

Their original goal in becoming business owners (less than 2 percent of the U.S. population owns a small business with employees) was to provide a living for themselves. Julie says they’re both very goal-oriented, competitive and focused. Throughout their careers, they set one goal, reached it and then immediately set another. It took them several visits and many sleepless nights to decide that buying a 25,300-square-foot building was a good idea. Part of their success has been help and advice from their management team, and their CPA, lawyer, banker and other seasoned advisers continue to provide direction. As the result of much discussion among all the voices, they devised a Plan A for the new building acquisition and remodel. But they also had a Plan B and Plan C if Plan A didn’t work.

They left the old building with a team of six and now have 14 folks on board: 9.5 techs and 4.5 admin people. (By my definition, a “tech” touches the vehicle and an “admin” does not).

In their successful efforts to be different from any other local shop, they’ve always worked hard to project a consistent image of professionalism. Part of those consistencies are the written work processes that govern their production areas. They have a distinctive and professional-looking logo and advertise using the same catchy radio jingle. Julie says that when their employees are out and about wearing their logo shirts, people often sing the jingle back to them.

The Road to Gold

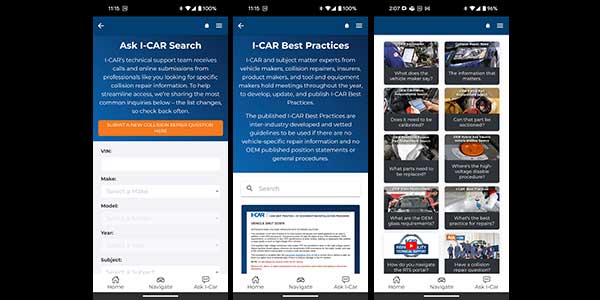

They always knew about and participated in some I-CAR classes. They knew of Gold Class but had not examined the program closely. With both their insurance company partners and car manufacturers looking for – or soon requiring – evidence of training, they embraced the program and set a goal of Gold Class status to demonstrate their commitment to excellence.

I’m a huge I-CAR fan and leap to their defense whenever I can. I always point out that formal, accredited education of any field in the U.S. is often subject to laws, requirements and stipulations that are not apparent to the students in the seats. Class content changes as the industry changes. Any non-profit organization trying to educate an entire industry depends on volunteers. While they may not all be Jay Leno, they’re giving back to our industry in the most personal way and deserve everyone’s appreciation. Thank you, I-CAR instructors.

The Steinbergs recognized that evidence of formal training would soon be a requirement of OEMs’ certification but was also a great marketing differentiator. Once they accepted that I-CAR Gold Class was the best route available to prove their competence, they enrolled in the highest level of training possible. Julie said their “Road to Gold” took about two years, including training prior to the 12-month time requirement, and cost them around $10,000. I agree with all of her conclusions and think this is the best money any shop can spend. Whenever I’m asked for a shop recommendation in an unfamiliar city, my answer is always I-CAR Gold Class. I tell them that the time, money and effort that shop expended to hang that little sign on their wall is all the proof I need that their car will be repaired correctly.

They designated four techs: an estimator, a structural tech, a nonstructural tech and a refinish tech to complete the entire series of role-relevant classes for that discipline. Many classes are offered virtually and online. Their welding certification was on site using their own equipment. Several times, they travelled to attend class and twice they’ve set and held their own classes onsite. All other non-designated techs, except their wash bay/porters and office staff, must have six hours of I-CAR-approved continuing education (CE) every year. Their paint company’s programs often qualify; ask first if your paint brand’s classes meet the CE credits requirement.

North Iowa Collison has monthly all-shop meetings and constantly sells the idea to their staff that this is the future path to success: formally-trained technicians, a welcoming presentation, recognition as a different and desirable choice in the market and, of course, to quickly deliver and stand behind an invisible collision repair. The clean glass door and the Gold Class sign get customers in the office, but their unwavering commitment to customer satisfaction keeps them coming back and the shop growing. It was a treat to stumble across a shop doing so many things well.