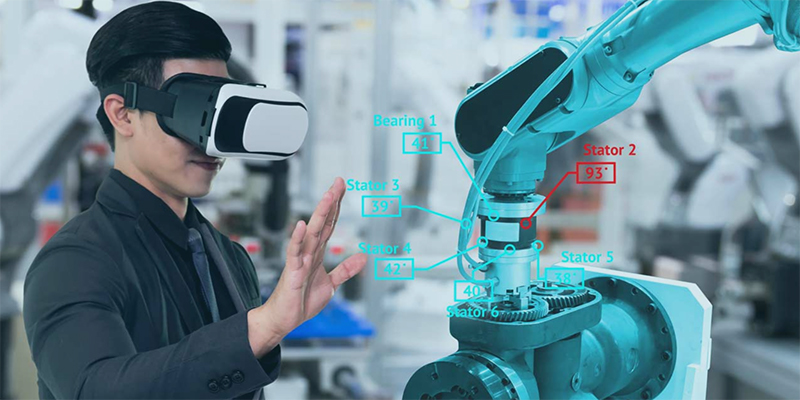

Researchers at Tradiebot Industries and Deakin University are currently working together to develop the collision and automotive repair industry’s first virtual/augmented reality training and service solution, according to a Robotics Today article. Together, they will work on a research project to develop an Industry 4.0 training system and explore how it can benefit the auto industry.

This project will be responsible for developing the industry’s first VR/AR training system that would redefine the way information, communication and training is delivered for existing repairers and those seeking a career in the industry. The project is being developed using Deakin University’s CADET Virtual Reality Lab – the first of its kind in the world. Users can walk around, walk through, and even touch objects in the virtual world and test systems and products that are yet to be realized using virtual reality technologies.

“Like many trades, our industry is facing a serious shortfall of skilled talent and an ever-widening skills gap as repair businesses struggle to keep up with the latest OEM repair methods and industry best practice,” Mario Dimovski, founder of Tradiebot Industries told Robotics Today.

Ben Horan, director of the CADET VR Lab at Deakin University, said that this type of immersive reality provides an opportunity for those interested in joining the collision repair industry to overcome some of the skills training challenges in the sector.

“Virtual Reality can provide access to training environments which are either difficult to access or don’t exist, and Augmented Reality can help provide digital assistance while performing a task,” Horan told Robotics Today.

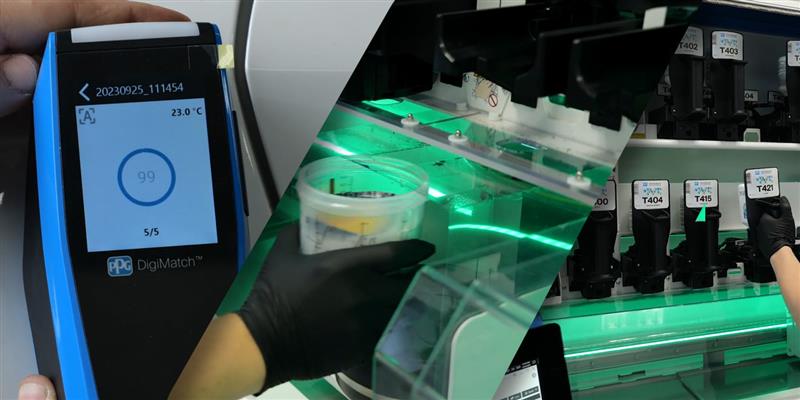

Dimovski said that instead of waiting for the tech, they are developing to make it to the real-world shop floor, creating a lapse in talent, the project is partnering with leading employers like PPG and Capital S.M.A.R.T Repairs who will be deploying the tech.

“PPG has a longstanding reputation as an innovator, so it is perhaps no surprise that we are always keen to welcome exciting new innovations and support their transition to market,” Kevin Woolerton, business improvement manager for PPG, told Robotics Today. “The collision repair industry is constantly changing and, with each evolution, new technologies arrive and are embraced before going on to become part the ‘new normal’ repair process.”

Outside VR, Tradiebot is also working on developing “Prep-bot” systems that use 3D scanning and robotics to perform basic labor duties in body shops such as parts preparation, and panel cleaning and quality inspections. Processes would be performed with skilled human assistance and would improve quality, accuracy and productivity, according to the company.

In addition, the company is also researching the use of plastics and carbon fiber to determine if it’s possible to supply on-demand 3d printed parts. The company is currently working with collision industry partners to create a more efficient and cost-effective method for manufacturing parts that are unavailable to be bought separate, out of stock or discontinued.