More than 30 years ago, I was the proud owner of my first car, a 1973 Ford Maverick. It had a 302ci V8 under the hood, and it sure beat driving a car with a four-banger like most of my friends had. I had the power. I had the speed. I had some control (steering and suspension were suboptimal at best). Most importantly, I had freedom!

It was mine, and I was happy driving my baby all over the Southwest. I may have strayed further from home than I should have at 16, but you’ve got to live a little, right?

I could afford the gas and insurance (well, some of the insurance…thanks, Dad!). What I couldn’t afford was taking her into the mechanical shop for repairs. I would do my own oil changes. I did my own timing, point gapping, tune-ups and carburetor tuning. I have one thing to say about that: thank God for electronic ignition systems.

The first thing my dad said to me when I started working on my own cars was, “Figure it out.” Well gee Dad, if I had the answer, I wouldn’t have waited all day for you to come home from work so I could try to rope you into helping me fix the car. After all, I did have a date to go on. Come to think of it, he may have seen me coming from a mile away and already knew I had to figure it out so I could pick up my girlfriend and head out to…nevermind.

Well, figuring it out wasn’t fun. I spent hours and hours trying not to break parts as I took them off and on. I replaced a number of them because I was trying to “diagnose” an issue. That got expensive in a hurry. Finally, standing at the parts store (yet again), I noticed an aftermarket repair manual for my 1973 Ford Maverick sitting on a shelf for sale. Eureka! I found repair information for my car and I would never have to ask another question again! Well, that’s what I thought anyway.

The repair manual wasn’t perfect, but it helped me understand how complicated repairs can be done without having to rely on experiential or “I think it goes like this…” statements with Dad, Uncle and Grandfather all standing over my shoulder debating the best way to take the carb off – all the while watching me break more damn parts on my car. “Don’t be so rough.” Thanks again, Dad.

As a teenage driver, I found out that I was hard on the body parts as well, which led me to my first experience with body repairs. While the manual wasn’t perfect for mechanical repairs, it completely lacked quality body repair information. As such, my beautiful Maverick had some blemishes that were “repaired.” But trust me, I should have left those dents and dings alone.

As a teenage driver, I found out that I was hard on the body parts as well, which led me to my first experience with body repairs. While the manual wasn’t perfect for mechanical repairs, it completely lacked quality body repair information. As such, my beautiful Maverick had some blemishes that were “repaired.” But trust me, I should have left those dents and dings alone.

Today’s Reality

“We’re getting to structures now, with multiple different materials, because of CAFE standards and heightened occupant safety standards, that do not perform the way they did five years ago, no less 30 years ago,” says Mark Allen, Collision Programs manager for Audi of America. “They’re performing very differently and controlling the crash energy very differently.”

“With the emergence of aluminum and other construction materials such as carbon fiber, magnesium and more exotic steel alloys, this situation is just going to get worse,” said Bill Fowler, retired and former collision repair shop owner. “The advent of the aluminum F-150 was one of the reasons for my withdrawal from the business.”

With the amount of time invested for training and capital equipment upgrades, Fowler isn’t the only person making hard decisions about their future in the collision industry.

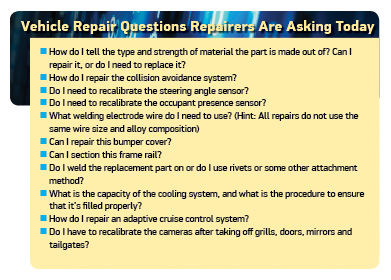

Combine these new construction materials and manufacturing methods with a network of sensors, control modules, occupant safety equipment, etc., and working on that 73 Maverick is considered child’s play. However, as an industry, that’s where we continue to have that “figure-it-out mentality” that still haunts us.

“I think there is still a pervasive belief from technicians that says, ‘I’ve fixed cars for 30 years and I know how to fix them’ and there is a lack of understanding of the ways in which modern vehicles have been developed,” says Aaron Schulenburg, executive director of the Society of Collision Repair Specialists (SCRS). “What we’re seeing are very advanced technologies, very advanced materials and very advanced structural elements found in the most common vehicles in the marketplace.”

It’s easy for collision shops to fall back on the old way of thinking that says, “Well, those are the high-end vehicles, and we’ll never see those types of vehicles in my shop.” But when you look closely at a high-volume vehicle, such as a 2016 Honda Civic, the “2016 Honda Civic: New Model Body Repair Information” bulletin, distributed by Honda, tells a much different story.

Vehicle substrates include high-tensile strength steel (HSS), ultra-high strength steel (UHSS) and a steel center pillar stiffener that is made from 1,500MPa (Megapascal) steel that is significantly stronger than the UHSS steels the industry has been introduced to in the last several years. Combine that with a number of electronic features: Adaptive Cruise Control with Low Speed Follow, Lane Keeping Assist System, Road Departure Mitigation and Collision Mitigation Braking System with pedestrian sensing capabilities, and what you get is an extremely complex vehicle to work on in your shop. Did I mention that the rear frame rails are 1,500MPa steel and can only be replaced as an assembly (i.e. no sectioning)?

According to Chris Tobie, collision business specialist at American Honda, “Because of the rapid body technology changes, two model years of the same vehicle may appear similar but employ very different body structures, requiring completely different repair procedures.”

Greg Solesbee, operations manager of Solesbee Auto Crafts, added, “The automotive repair industry is just now coming out of the Stone Ages. You can’t simply do things the way you choose or want. Today, everything is so highly regulated and you have to prove your way through it. This is foreign to a lot of people and very time-consuming, especially to an estimator. You have to set up your business to do the research on each vehicle. If we don’t get it [a particular vehicle] in our shop that often, we do even more research on how to repair the vehicle properly.”

This poses a challenge for an industry used to accepting that the same repair procedures are valid from model year to model year until there’s a big vehicle redesign.

“To repair today’s vehicles properly, it’s no longer as to whether you want to seek out the OEM repair information, it’s a requirement,” says Dan Risley, president and executive director of the Automotive Service Association. “Having access to OEM information on every vehicle is mandatory to properly repair today’s vehicles. If you don’t have the information, you’re going to repair it wrong.”

According to collision industry leaders such as the OEMs, trade associations and I-CAR, shops need to look up repair procedures every time a vehicle comes in for repairs.

“Every time you do that repair, even if you’ve done that one before, what you printed off today is not valid tomorrow,” says Allen.

“It’s imperative that shops have access to the most current version of that vehicle’s collision repair information from the OEMs,” confirmed Jason Bartanen, director of Technical Industry Relations for I-CAR.

Another question shops must tackle: “Is researching and paying for the OEM information a cost of doing business, if I have to look up repair information for every vehicle that rolls through my shop?” Remember, not just the first time you work on a vehicle, but every time, you should be researching the proper repair procedures.

“This is necessary work, and shops should be charging for the work that they do,” says SCRS’s Schulenburg. “They should be identifying their charges and charging accordingly. It’s not a cost of doing business, and they should be charging appropriately according to their business model.”

“Severity drives the need to look at the OEM information,” says Gary Antonelli, collision center manager at Turnersville Collision Center. “Rails, structure, maybe rear body panels, something that’s the heart of the car, we’re going to go in and print off the instructions to make sure that we’re doing things correctly.”

Added Aaron Delano, damage appraisal specialist at Ron’s Collision Center, “During our disassembly process, it’s our technicians’ responsibility to gather the OEM information on that vehicle. They’re able to add notes to each vehicle, and they have a packet of information that follows the vehicle through the repair process. The technicians staple the information to the sign-off sheets, and that’s how the information is passed along to the other technicians.”

There’s also the question of when to incorporate the OEM info into your repair processes. At minimum, you want to have access to the OEM info available in the blueprinting or repair planning stages. Ideally, you would open it during the estimating process. Having proper OEM documentation in your hands at the time of the “adjuster visit” or “desk review” is key to conveying all of the repair operations necessary and needed to be paid for.

“When you write an estimate scared, you’re going to skip procedures, you’re going to cut things off the estimate and you’re going to do things because you’re afraid that the insurance company is going to critique your estimate. I’ve watched this happen, and it’s quite the opposite if you simply prove with documentation why,” says Solesbee.

Where to Find It

So, where does a shop begin if they’re new to using OEM information during the vehicle repair process?

Let’s start with the OEMs themselves. Each OEM has a website that allows you to access their repair information. In most cases, you’ll be required to pay a price for access. The easiest way to access the OEM sites is through the OEM1Stop website (www.oem1stop.com).

Another option is using the I-CAR RTS (Repairability Technical Support) Portal (rts.i-car.com).

“As an industry-recognized collision repair training organization, I-CAR has become the conduit between the OEMs and collision repair facilities,” explains Jason Bartanen, director of Technical Industry Relations for I-CAR. “I-CAR works with the OEs to share collision repair information with the industry and to identify the gaps that exist within the current repair information.”

Through the coordinated efforts of the OEMs and I-CAR, higher quality repair information is being distributed to the collision industry.

Finally, there are a number of third-party companies that provide direct OEM info through licensing agreements: ALLDATA Collision, Mitchell’s Tech Advisor and CCC’s Repair Methods (only available for CCC’s existing customers). Third-party options are great for those who want all of the info for a fraction of the price subscribing to all the OEM websites would cost. However, customer support varies, so make sure you answer this question: “If I have a desperate need for additional OE information, whom would I most like to be speaking with in order to get my issue resolved?”

The Final Word

If you’re still on the fence about the need for OEM information, think about this statement from John Hughes at Fiat Chrysler Automobiles: “If it’s written in the repair information, you have to do it, period. If you don’t do it, you’re circumventing a repair procedure and you’re not giving the customer what they paid for.”

From a shop’s perspective, liability should be a concern when deciding against using a documented OEM procedure.

“Yes, there’s an incredible amount of liability that that entails,” says Delano. “If you fix a vehicle improperly, then you’re affecting the structural integrity of the repair. If that customer ever gets in another accident, and it’s determined that we did an improper repair, then there’s a ton of liability.”

Incorporating OEM info into a shop’s repair process is necessary for survival, not only from a liability standpoint but also from an adaptability standpoint. If a collision business is not constantly growing and changing with the times, it’s going to fall behind quickly.

“I predict that if you don’t change old ways in about the next three years, and if you haven’t made significant changes this year, then I fear that many of us will find ourselves in an unrecoverable state, which for some will be out of business,” says Solesbee. “Things are changing way too fast. Way too fast.”