Is there really a difference in preparing a repair estimate for a high-end vehicle versus a high-production vehicle? The answer is a resounding no!

Is there really a difference in preparing a repair estimate for a high-end vehicle versus a high-production vehicle? The answer is a resounding no!

Although certain exotic vehicles, such as the Aston Martin, Bentley, Ferrari, Jaguar, Lamborghini, Maserati, Nissan GT-R and aluminum intensive vehicles are best examined, estimated and repaired by properly trained and certified technicians, the same is true for steel production vehicles such as the Mercedes-Benz, BMW, Audi, Toyota and Volkswagen. Regardless of the vehicle’s design and substrate construction, education and training is crucial to ensuring that proper and safe repairs are outlined in the repair estimate. Thus, the procedures to write a proper estimate are the same for all vehicles.

Times Have Changed

Years ago, collision repair was pretty easy. If a vehicle was damaged, you looked it over, ordered the parts you couldn’t fix (like moldings, lamps and plastic grilles) and began repair with heat and lots of body filler, replacing only those components that were totally unrepairable. The old so-called “tanks” were easier to estimate because they were easier to fix. This is because they were generally constructed with mild steel/soft steel (MS/SS), which can be easily repaired using the most traditional method of heat and hammers. In addition, there was almost no collision energy management or crush initiators built into those vehicles. So, along with these vehicles being unsafe (by present day standards), there was very little collateral damage outside the point of contact.

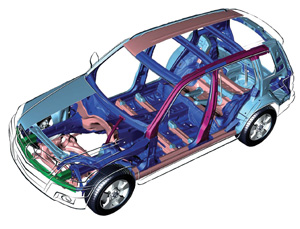

But as vehicle design changed and crash energy management was integrated into more vehicles, estimating became more complex. Today’s vehicles are highly advanced and well-engineered, utilizing multiple substrates joined by different methods. These advances require today’s estimators to know not only the basic estimating procedures but the proper and accepted repair protocols.

Proper Procedures

Let’s look at the proper procedures to estimate the damage sustained by a vehicle during a collision event. The most important thing to remember is that an estimate is an opinion – an approximation, anticipated cost or a tentative price. Today’s estimates should more resemble blueprints, or accurate plans for processing the repairs and procedures, rather than traditional estimates.

The first step to any vehicle analysis is to obtain information from the vehicle owner about how the collision event occurred. This should include the conditions surrounding the collision such as cause (mechanical malfunction, inattentive operation, etc.), impacted object (vehicle, stationary object, barrier, pedestrian, etc.) and the vehicle’s operational status (driving or parked). The next steps are as follows:

1. Wash the vehicle. Washing the vehicle will ensure that all grease, road debris, leaves, wax and Armor All is removed. Once the vehicle is clean, you’ll be able to gain an unobstructed view of the damage, and the vehicle won’t contaminate the shop or spraybooth.

2. Photograph the vehicle (four corners, VIN label and plate, mileage, damaged area, vehicle disassembled, etc.)

3. Perform a walkaround. While taking notes, start in the opposite corner farthest from the damage; check the operation of all of the closure panels and panel gaps; perform a quick check of all four wheel positions; and look at the vehicle from all angles for any collateral damage as you walk toward the point of impact (POI).

4. Now that you have a good idea of the amount of damage the vehicle has sustained, you’ll need to go to either the OEM website or other source of vehicle information to view the repair precautions and procedures for the vehicle.

5. Check the area at the POI. Either take notes of the damaged components and the required replacement or repair procedures. Or, if you have a laptop, just enter everything into the computer.

6. In order to view the structural components, partially disassemble the vehicle by removing the damaged components

7. After the partial disassembly, take more photographs.

8. Following the EME 54 Theory (see pg. 26), measure the vehicle either by tram gauge, tape measure or even better, a three-dimensional electronic measuring system. Measuring the vehicle is the only way to write an accurate blueprint. And don’t forget to take photographs during the measuring process.

9. After taking all the measurements, you can now decide if the vehicle needs to be placed on an SRA, if any additional anchoring will be required, if any components will need to be removed and the amount of pulls to realign the vehicle if allowed by the OEM. BMW 5 and 6 series, Audi A8, Porsche Panamera, Lamborghini, Aston Martin and Ferrari are some manufacturers that prohibit structural pulls to their vehicles. Keep in mind that some OEMs dictate that their vehicles can only be repaired on certain SRAs with specific procedures. Not following those requirements may result in an improper repair for which you may be held liable.

10. Write notes on the vehicle panels so everyone can see what procedures need to be performed (i.e. R&I, RPL, BLD, RFN, etc.).

The EME 54 Theory

E = Every collision-damaged vehicle must be measured.

M = Most measured vehicles will need to be structurally realigned.

E = Every structurally realigned vehicle will require an all-wheel alignment check.

5 = the number of areas to measure: underbody, underhood, side structure, glass openings/trunk/ hatch area, suspension position.

4 = the number of times the vehicle needs to be measured: estimate, first time on the SRA (Structural Realignment Apparatus), during the repair/replacement/realignment process and finally for documentation after repairs.

OEM Guidelines

Now it’s time to recheck the OEM repair procedures to see if there are any special products that need to be added to the blueprint. The following is a list of some of the additional products that may be needed to perform necessary repair procedures:

1. OEM rivets are required on almost every structural replacement procedure for aluminum intensive vehicles, but they’re also required on many steel vehicles, too – Mercedes-Benz and GM, for example. Mercedes-Benz requires OEM rivets and OEM structural adhesive to be used in areas the squeeze type resistance spot welding (STRSW) arms cannot access or when replacing USIBOR (boron) components. GM requires OEM rivets and structural adhesive to attach the replacement lower front uni-rail when the vehicle has a laminated dash panel/firewall. These rivets can range in price from $1.25 up to $3.95 each, and the procedure can require anywhere from 12 to 40 rivets. The rivets are sometimes available only in 100-

count packages.

2. Structural adhesive is required on almost every structural replacement procedure for aluminum intensive vehicles and steel vehicles that feature OEM rivets. Some OEM procedures require the adhesive to be used in conjunction with STRSW, while others dictate just adhesive bonding on the non-structural panels. Other OEMs allow multiple choices on what brand of adhesive can be used, while still others require specific products. These structural adhesives can range from $19.95 to $300 per tube.

3. Most manufactures have sectioning procedures available for their structural components. If there isn’t a procedure, it generally means full part replacement only. Honda/Acura is one example of an OEM that has no front uni-rail sectioning procedures on most of its vehicles; conversely, GM and Toyota do offer front uni-rail sectioning procedures for most of their vehicles. Always refer to the OEM website or other source of vehicle repair information.

Get In the Know

So what else does an estimator need to know? Among other things, he or she needs to understand the types of materials used in the construction of today’s vehicles such as:

• MS/SS, interstitial free (IF) steel

• Interstitial free – high strength (IF-HS) steel

• High strength steel (HSS)

• Bake-hardenable (BH) steel

• High strength-low alloy (HSLA) steel

• Ultra high strength steel (UHSS)

• Advanced or extra high strength steel (AHSS/EHSS)

• Boron/USIBOR

• Ultra high tensile steel plates

• Martinsite

• Dual phase (DP)

• Transformation induced plasticity (TRIP)

• Aluminum (1000 through 7000 series)

• Composites such as plastic, fiber reinforced plastic (FRP) and carbon fiber plastic (CFP)

But there’s even more to know such as how the part is formed (hydroforming or is it pressed into shape?) and the construction of the part (i.e. how many reinforcements are sandwiched between the inner and out panels). Simply put, today’s estimators need to know not only their intended job but the procedures of the repair technician and insight into engineering and material science used in vehicle construction. Estimating repairs of more sophisticated vehicles is a procedure that requires the preparation of a “blueprint” of repair to accompany his or her estimates of cost.

As you can see, there’s a lot that goes into writing a proper and accurate blueprint, regardless of the value of the vehicle. The most important thing to remember is that you must train and educate yourself to be the best.

Larry Montanez, CDA, is a former I-CAR ATC, and is co-owner of P&L Consultants, which works with collision repair shops on estimating, production and proper repair procedures. P&L conducts repair workshops on MIG and resistance welding, measuring for estimating and advanced estimating skills. P&L also conducts classes for IACDA. Montanez also works at Lange Technical Services. Ltd., and conducts investigations for insurers and repair shops for improper repairs, collision repairability, collision reconstruction and estimating issues. He can be reached at (718) 891-4018 (office), (917) 860-3588 (cell) or [email protected].

Jeff Lange, PE, is president of Lange Technical Services, Ltd., (www. LangeTech.net) of Deer Park, New York. Lange is a licensed New York State professional engineer who specializes in investigating vehicle and component failures. Lange Technical Services is an investigative engineering firm performing forensic vehicle examinations and analysis for accident reconstruction, product liability and insurance issues. The company conducts training classes for insurers, law enforcement and IACDA. Lange can be reached at (631) 667-6128 or Jeff.Lange@ LangeTech.net.