Representatives of Ford Motor Company offered a more detailed look at the military grade, aluminum alloy 2015 F-150 at the Collision Industry Conference April 9 in Portland, Ore., with the goal of providing collision repairers with the repair information they need prior to the best-selling truck hitting showrooms this fall.

Representatives of Ford Motor Company offered a more detailed look at the military grade, aluminum alloy 2015 F-150 at the Collision Industry Conference April 9 in Portland, Ore., with the goal of providing collision repairers with the repair information they need prior to the best-selling truck hitting showrooms this fall.

Repairability

One point that was emphasized several times was that, from when the vehicle was first conceived at Ford in 2009, engineers discussed not only whether the vehicle was feasible to build but easily reparable.

“Design for repairability was No. 1,” said Larry Coan, damageability product concern engineer for Ford’s customer service engineering group. “We meet with the engineers and go over vehicles early in the design, and if we recognize any concerns with collision, we take it to the engineers and figure those things out.”

According to Coan, the high-strength steel frame will be sectionable, with front stub, front third and rear third available sections for service, but the key difference is that there will be separately serviceable front lower control arm mounting brackets.

There are sectioning procedures for the floor pan, too, where you can section the floor pan skin in many areas and also section the floor pan crossmembers. And repairers will have a choice of two different repair methods: rivet bonding or welding.

“In a lot of areas on this truck, you will have a choice based on the skill of the technician as far as which way you want to repair it,” Coan said. “So you don’t have to weld if you don’t want; you can rivet bond.”

The front apron tubes on the 2015 F-150 were designed with reparability in mind, too. On the current F-150, it’s a two-piece system of hydroformed steel. Two sections go inside the hinge pillar, and to remove and replace the part, you have to drop the instrument panel to get to the backside of the hinge pillar and drill out the spot welds. But on the 2015 F-150, it is now a single piece with all external joints.

“You don’t have to get into the hinge pillar or instrument panel, which will save a lot of hours,” said Coan. “We thought it was a big win.”

As far as the B pillar is concerned, if it takes a hit and the rockers and crossmembers are damaged, you don’t have to replace the entire assembly, according to Coan.

“You can section it in by building a backer and either welding or rivet bonding in the joint. You can section the inner and outer rocker panel on the regular cab and super cab, but the exception is the crew cab. In the crew cab, the outer rocker reinforcement in front is an extruded part, so you would have to replace it in its entirety.”

The B pillar itself has an improved design, said Coan, in that the mounting tab stops short of going over the roof tube and underneath the roof panel. Therefore, you don’t have to cut access to the roof panel or pull the roof panel to remove and replace the B pillar.

“In not having to touch the roof, it’s a very easy, straightforward repair,” said Coan.

As for the A pillar tube, you can section it right on top of the B pillar so that replacing the entire assembly won’t be necessary.

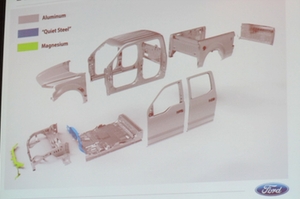

There are no castings in the truck; everything is a stamping, extrusion or hydroformed piece.

Every sheet metal part will come with an instruction sheet in the box detailing all the procedures to remove and replace or section and listing the parts needed, such as rivets and adhesive.

Coan’s final point was that, when you look at accident data and see that 80 percent are light hits that impact bolt-on parts and bumpers, most repairs on the F-150 will be nothing new.

“The bumpers on this truck are still steel bolted, the grille is still plastic and the headlamps are still plastic. So a lot of collisions you’ll be dealing with will be business as usual.”

Certification/Recognition

Addressing certification, Paul Massie, powertrain and collision product marketing manager for Ford, said Ford will be developing a national body shop network where dealer shops will have the opportunity to become “certified” (because dealers in the past had a program called the “certified collision repair network” and Ford wanted to retain that for them), and independent shops “recognized.” However, if a shop is neither, it can still obtain parts.

“Ford is not going to restrict parts sales,” said Massie. “The majority of parts is business as usual – steel bumpers, grilles and lights. It doesn’t make sense to restrict those. You can’t mainstream something if you’re restricting parts sales.”

Eighty percent of Ford’s customers go to independent body shops because less than 50 percent of their dealers have a body shop. Of those who have one, only 800 are truly embedded in the collision business, said Massie.

“We realized we could not have a mainstream repair process if we only directed our customers to dealers. Besides, the customer may not want to go to a dealer because they have a good relationship with an independent.”

The national body shop network will be administered by Assured Performance. The annual cost is $2,950, which will include both general repair and aluminum repair certification/recognition. Shops on the program will receive signage, marketing materials, business development support and inclusion in a national body shop locator.

“Will everyone be on our program? No. Will some of those shops not on the program be capable? Yes. But for those who want to be recognized by Ford and listed on the locator, we think that will be the primary driver,” said Massie. “As the F-150 gets out there and the customer wants to know where they can take it for proper repair, we need to be ready to point them in the right direction.”

According to Massie, Ford will require a dealer sponsor for any independent shop that’s in the network. In the case of a dealer without a shop that’s working with an independent shop, they may choose to sponsor that shop. A shop that is not a dealer’s preferred shop could still be nominated by its wholesaling dealer.

Shops that wish to be on the program will have to complete the general repair requirements in the Assured Performance program in 2014, at which point they would be recognized by Ford and included in the locator. By December 2014, they will need to also be aluminum capable to remain on the program for 2015 and beyond.

“If you aren’t aluminum capable by that point, you won’t be allowed to be in the program for 2015, even in general repair,” Massie said. “So, by 2015, you will need to be recognized for both general and aluminum repair.”

Training

Coan said there will be three training courses offered. One is a Web-based Body Shop Essentials course accessible to dealers via the Professional Technician Society website and accessible to independents via www.motorcarservice.com.

Two others will be I-CAR courses, one for structural repair and another for welding.

Independents and dealers enrolled in the national body shop network will have priority in I-CAR training enrollment, which starts in June.

“In working with I-CAR up front, we were actually able to put together the training materials and get techs trained before the vehicle hits the street. A lot of techs will be trained this summer before the vehicle is out there,” Coan said. “Someone will wreck their vehicle on day one when they drive it home from the dealer, so we wanted to make sure that people are out there ready to fix it.”

Tools and Equipment

Coan says Ford thought long and hard about tools and equipment, and consistent with their goal of “mainstreaming” repair, they decided not to specify certain makes and models but rather offer general guidance as to what repairers will need technology-wise to repair the F-150. That includes:

• 220-volt pulse MIG welder dedicated for aluminum

• Separate hand/power tool kit dedicated for aluminum

• Dedicated aluminum dent extraction system containing an aluminum stud welder, heat gun, pyrometer, aluminum hammers and dent extraction systems

• Dedicated aluminum dust extraction system with wet mix technology – system can be portable or a central installed system

• Have a work separation system that isolates aluminum vehicles from vehicles undergoing steel repairs – separation can be a separate room or curtain system

• Have a specialized aluminum SPR (self-piercing rivet) gun approved by Ford Paint and Body Technical Center

• Optional equipment: a select number of qualifying frame alignment accessories are available for Chief and Car-O-Liner frame systems

• Optional equipment: Fume extraction systems can be permanently mounted or portable

*It was previously noted in this article that the Henrob rivet gun was the only rivet gun approved by Ford. This is FALSE. the PR-5 riveter from Pro Spot is also approved.

Insurer Involvement

As part of Ford’s communication plan, the automaker shared information on the F-150 with insurance companies from the start so they would understand the proper repair procedures and be able to write proper estimates.

“To date, State Farm will be sending all their estimatic personnel through I-CAR training,” Coan says. “Allstate will be providing a series of webinars for their folks, and we’re reaching out to other insurers as well.”

Technology

Coan said Ford didn’t set out to build an aluminum truck but rather the “toughest, most capable and best truck we ever had. It just so happens that an aluminum alloy body got us there.”

To that end, there are new “class-exclusive” features such as: 360-degree cameras in the front and rear of the vehicle and side mirrors that offer a bird’s eye view around the truck; 400-watt power inverters for charging tools; LED headlamps; LED lighted bed; power liftgate operated by a key fob; forward collision warning with brake support; lane departure warning; blind spot monitoring system; and cross traffic alert.

The 750-lb. weight loss due to the aluminum body translates to greater efficiency, capability, towing and payload, Coan said.

“It also allowed us to put a smaller displacement engine in the truck and still get a lot of power, capability and performance. One engineer said he could feel the difference in the first 25 feet he drove in the truck.”

More information:

I-CAR Partners with Ford to Launch 2015 F-150 Training Program