It was damn cold and rainy that morning. In my book, there’s just nothing worse than a late February rain with temperatures hovering just above freezing. Even more distressing to me than that was that it was 7 a.m. on a Saturday. To say that I was reluctant to get out of my warm bed after a long week of travel is an understatement. My manager and good friend Tom insisted that I attend the annual Alliance of Automotive Service Providers-Illinois (AASPI) meeting that day. I’ve attended hundreds of collision industry meetings, trade shows and seminars all over North America, but this meeting was different.

After the audience filed into the room, Wade Ebert, the AASPI president at the time, introduced the keynote speaker. I immediately recognized the presenter, a quiet and reserved gentleman I had been speaking with in the hallway before the doors opened. The man was very pleasant to me as we spoke over coffee (mine) and a Red Bull (his). But reserved people don’t necessarily make great presenters, so when I saw him take the stage, I wondered how I was going to stay awake during his presentation.

After a nice round of applause, Mike Anderson, president of Collision Advice, took the podium and my entire view of the collision industry changed forever. Anderson’s somber demeanor suddenly changed as he stood in front of that audience. He immediately engaged them with challenging questions and provocative content. Actually, it really felt more like Anderson strapped a saddle around the audience and rode us all morning until he broke down the many assumptions and misconceptions we held onto in that room.

I’ve never forgotten his presentation to this day. My two biggest takeaways from this encounter are simple and precise: if you don’t have the proof to substantiate your argument, it’s just your opinion. I also learned that Anderson did not need that last Red Bull out in the hallway.

Face the Facts

Let’s face the facts, in the collision repair industry, we are not returning 100 percent of accident-damaged vehicles to our customers with 100 percent of the accident damage repaired. One major area we’re lacking in is making sure every vehicle is within specification in regards to their measurements. Stated another way, are you measuring every vehicle that rolls through your doors? Why not?

What gets us in trouble is that we’re humans, and most humans are, by nature, lazy. The “I didn’t have time to do that” argument is not going to get you out of a jam with your customer or insurance partner after the repair is completed. When I hear that phrase, it instantly indicates to me that a shop’s repair processes are not designed to ensure 100 percent quality at every stage. Pre-measuring a vehicle before you begin work on it is just as important as performing a pre-repair diagnostic scan.

Frankly, you’re not going to be able to charge for measuring if there is no structural damage found. However, you will be able to offset this investment with additional revenue generated by finding additional damage that would have otherwise gone unnoticed. Hidden damage is much easier to find when you’re looking for it.

Identifying and documenting the additional damage adds to your bottom line. It’s just as important to count the additional frame time on your estimates as it is to track the reduction in panel fit time during the final assembly stage.

“The guys waste more time at the end making things fit, if they measure the vehicle after the fact,” says Rick Hatswell, COO of Craftsman Collision.

From a business process standpoint, it just makes sense that you have the vehicle as close to pre-accident condition as possible before the final assembly. If you have 100-percent quality control built in at every stage, then your chances of achieving success are greatly enhanced.

Documentation

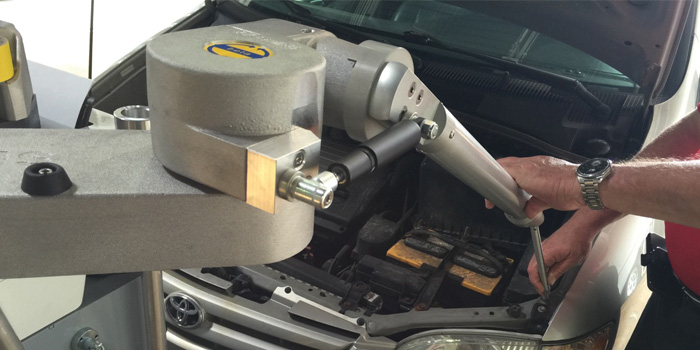

Measuring systems today are designed with documentation in mind. They’re also simple to use and have been designed to reduce setup time. Today’s 3D measuring systems are more portable than ever before. Auto-calibration features allow you to set up the laser heads without having to worry about leveling them for accuracy. In fact, some manufacturers allow you to adjust the laser heads during the measuring process, which then recalibrate themselves. However, these measurement systems usually require the vehicle to be off the ground.

Newer and more portable systems are available. These devices provide on-the-fly measurements and can be used far away from your frame benches. You can now take your measuring devices out of the shop, freeing up your frame bench and allowing you to gather critical data in your estimating bays or parking lot. The new touch-based and touchless systems are designed to allow the operator to locate the measurement point and register the measurement with the device software. Gone is the need to attach targets to the vehicle in order to get your measurements.

In addition, this new breed of devices allows you to measure body panels and other vehicle parts. Say you’re required to use an aftermarket panel and you want to compare it to the OEM panel to ensure proper fit before mounting the part. If the part is not within the OEM specification, you have a decision to make: send it back or mount it and charge for the extra time to fit the part. In either scenario, you have the necessary documentation to support your case.

Science and Art

With today’s manufacturing processes, vehicle panel tolerances have forced collision repairs to become just as much science as art. Not only is it a challenge to get structural repair information from some manufacturers, the OEMs are increasingly choosing to forego publishing their vehicle measurements.

Even with published OEM vehicle dimensions, you may have build data that is not usable within the collision repair process. Measurement locations can be covered or obscured to make using them a challenge or next to impossible. I commend those OEMs that continue to publish quality repair information, complete with upper body dimensions, as they help collision repairers make sure that their vehicles are repaired properly.

However, there is not a standard method of publishing vehicle dimensions and measurement points within the auto industry. This leaves a significant need for third parties to provide vehicle measurements to collision shops. There are several companies out there that provide this information, typically for use within their proprietary measuring or software systems.

What this means is that actual vehicle dimensions are averaged together, in many cases, to produce structural dimensions. For instance, if you measure five cars being unloaded from a truck or railcar, you’ll typically get five different sets of data. Before we jump off the cliff on this one, it’s important to understand that the discrepancies are adjusted out in the average and other data sources may have been used to validate the information before you use it in your shop. Finally, I recommend having a subscription to an OEM information source that provides dimensions in order to validate any questionable data.

Conclusion

New vehicle measuring system platforms, combined with a new battery of technologies, have made measuring vehicles faster and easier than ever before. Leveraging various strategies, including pre-measuring vehicles, can improve your production processes, eliminate wasted time during the final assembly of the vehicle and, more importantly, increase your profits.

Contributors to this article include Tom McGee – business development manager, Spanesi-Americas, Rick Hatswell – COO, Craftsman Collision, Richard Perry – OEM and strategic account manager, Chief Automotive Technologies, and Robert Watts – CEO, Advanced Measurement Systems.