The U.S. Department of Labor’s Bureau of Labor Statistics projects that 60 million workers in the United States will retire over the next 30 years. By 2014, the U.S. will need a projected 18,927,569 new workers. Plus, the first of the “Baby Boomers” are reaching retirement age, which will shrink the pool of available workers even further.

Consider your own employees. Workers in the collision repair industry often retire from this line of work well before they’re 65. How many of your skilled employees are 40 years of age or older? How many of you think that far ahead? These are the workers you will likely need to replace within the next 10 years.

You need to start recruiting and training new people now because, like the marathon runner, if you wait until you’re thirsty to take a drink, it’s already too late because dehydration has set in. As an employer, if you’re waiting until you’re thirsty for new employees, dehydration will have already set in. You’ll then have to take steps to re-hydrate yourself and will pay the price in the end.

Mentoring Matters

Mentoring will play a crucial role in preparing the workforce of tomorrow, yet few small businesses realize this today or are taking steps to prepare for it. Staying on top of this is what sets some shops apart from their competitors. If you’re taking this issue seriously and are building an in-house occupational mentoring program, you’re among the enlightened few. You’re taking a drink today to fight off “employee dehydration” tomorrow.

Not feeling particularly thirsty yet? Read on. Once again, from the Bureau of Labor Statistics, the median age of the American worker has increased to over 40. Half of today’s workforce will qualify for retirement within the next two and a half decades. In the automotive industry, however, you should be even more thirsty than most.

Think about these statistics from the I-CAR Education Foundation’s “Snapshot of the Industry” survey:

• The average age of a worker in this industry is 38.7 years of age, which is up 3.2 years since 1995.

• The number of technicians in the younger age groups is declining, while the number of middle-age techs is growing.

• 24.2 percent of collision industry professionals are between 36 and 45 years old.

• 23.1 percent of collision industry professionals are between 46 and 55.

• 13.1 percent of collision industry professionals are 56 to 65 years of age.

• The largest group of collision industry professionals, those 36 to 45 years of age, will retire within nine years of one another.

• Since 1995, the percentage of 26- to 35-year-old collision industry professionals dropped from 37 to 22.1, and the percentage of new workers under 21 dropped from 9 to just 4.

The workforce in the collision repair industry is not only aging but leaving. The following statistics from the Employment Policy Foundation show that the industry is doing a poor job of recruiting and retaining new blood:

• On average, over 21,500 collision repair industry professionals leave the field. That’s 11 percent of the overall workforce.

• 61 percent of the professionals in the collision repair industry have been with their current employers for five years or less. Compare this to the overall American workforce, where 52 percent have been with their current employers for less than five years.

• The National Federation of Independent Business recently cited “the shortage of skilled trained workers” as their members’ No. 1 problem.

According to assistant secretary of labor Emily Stover DeRocco, “The skilled worker pipeline is leaking.”

Put these facts together, and the collision repair facilities that intend to stay in business over the long haul can reasonably predict that they’ll be fighting to retain their core employees while simultaneously watching more than half of their most experienced techs retire in the near future. This isn’t even considering that the collision repair industry typically loses 70 percent of its new employees due to unstructured methods of attracting, training and retaining people.

So the real question is, are you taking the steps necessary to “hydrate” your business before you’re thirsty? Few really are, and many could do a lot more. Others are in denial, and in the race for skilled technicians, they’ve left their water bottles behind. The enlightened few, however, who are armed with a bona fide apprenticeship program are taking in the fluids they need to stave off employee dehydration. Do you consider yourself among them? If so, are you an employer of choice?

Be the Choice

One of the most common complaints heard from employers is that they can’t seem to retain their employees and thus have a high turnover rate. But if employers would view themselves as employers of choice and “walk the talk,” this would not happen.

Over the past couple years, I’ve worked with employers to identify the underlying causes of high turnover. We’ve studied their internal culture, conducted exit interviews and made tough, to-the-point recommendations that they sometimes didn’t want to hear.

Sometimes the truth hurts, but the truth is what smart business owners and managers need from their employees, partners and consultants. Unfortunately, they don’t often hear it…or they ignore it.

If you have a high turnover rate, you need to take a critical look at yourself, your business culture, managers, equipment and facilities. If you do a critical assessment of all of these things, you’ll find areas that need your attention sooner rather than later. Pay attention to these things and change your culture, and you just might make your business an employer of choice.

So what does it mean to be an employer of choice? Employer of choice has been a popular buzz phrase that has been picking up more and more acceptance over the past few years. It means different things to different people. But it’s more than a phrase, it’s an actual way to run your business. It is the company culture. It means the following things:

• People will actually choose to work for your company.

• Employees will choose to dedicate themselves to your company’s success.

• Most people will choose to stay with you, even if they’re wined and dined by other potential employers in your field.

Stabilizing the workforce will be a huge competitive advantage for businesses across the country in the years to come. The ultimate challenge will be to attract, train and retain the workforce of tomorrow, and effective apprenticeship and occupational mentoring programs will be a key component of this. The most successful shops will be the ones that inspire new talent to come aboard and further inspire them, and existing talent, to stay with them when considering other options.

If your place of employment is like this, you’ll enjoy an ongoing, competitive advantage. While your competitors are playing “musical chairs” with experienced technicians, the stability you enjoy will allow you to focus on other important matters in your business, things that never make it off the back burner at your competitors’ shops. Your competitors will be frustrated by the fact that they can’t steal your employees away from you. They’ll continue to look outside of their businesses to find the answers to their challenges instead of looking inside to see the real problem. This will put them further and further behind, and the gap between them and the local employer of choice will widen.

Reaping the Benefits

Some of the benefits of being an employer of choice are:

Marketing your business and recruiting top-shelf employees. Word of mouth is a powerful thing, and employers of choice earn a reputation that spreads from one person to another. People come to employers of choice, rather than the other way around. This can save those employers considerable cash in advertising and recruiting expenses. The cream rises to the top, and employers of choice can afford to be choosy about who they hire, especially new hires who they feel will fit the culture of the business. The focus of employers of choice is to choose the right person to hire rather than struggle to get people to apply in the first place.

Better people, higher productivity. It stands to reason that better people produce more. Better people who are also happy working for their employers of choice will produce even more than that. They’ll expect more from themselves and each other, and will take pride in training new people. Anyone who doesn’t fit in will often be excised from the company by employees before management steps in.

The team that remains will work better together because they won’t want to let each other down. Things will be done quicker, better, and more efficiently and accurately the first time, reducing comebacks and re-do’s. There’s a level of comfort, stability and trust that exists within the walls of an employer of choice. Long-term employees know the business inside and out and have a vested interest in seeing it succeed.

Choices are made to work and to stay. Just as people make a choice to work for a certain employer, they also have to make a choice to stay or go somewhere else. Employers of choice have less to worry about in that regard. The longer a quality employee stays with an employer of choice, the more the employer benefits from his performance and from not having to replace him and train his replacement. There’s a high level of trust between management and long-term employees at an employer of choice. And the trust is strong between employees, too, creating an atmosphere of familiarity and teamwork. Everyone’s needs are being met.

Less turnover, greater loyalty. Happy employees tend to stay with their employers. Employers of choice show appreciation for their employees’ hard work and provide appropriate praise and recognition. Happy employees who feel wanted and appreciated tend to stay. This reduced turnover adds to the bottom line and enhances morale and dedication to the employer as well, which in turn will enhance performance, quality and profitability.

Locating the best people. Imagine being such a great workplace that people actually seek you out. Being an employer of choice means you’re more desirable to your potential prospects. Employers of choice not only have better luck at finding good employees, the overall quality of all applicants goes up as well. Sub-par talent typically won’t even apply for work at an employer of choice because they know they can’t cut it there. Top-shelf employees seek out employers of choice because they can apply themselves, use their talents, be appreciated and be part of a superstar team. People seek places where they can “belong,” and stars want to belong to a star team.

Efficient, effective and profitable. Recruiting new talent is less of an issue for employers of choice because reputation and word of mouth will bring talent to their doors. Better still, because of the reputation of employers of choice, most of the less desirable candidates will actually pre-screen themselves and not bother to apply. This makes recruiting top talent more efficient and effective. It stands to reason, then, that the company will be more profitable as a result.

A file of great candidates on hand. Should someone actually leave or retire, employers of choice have less downtime because they usually have a file containing the applications of several top-level candidates. What a luxury it is to not have to run an ad and go through the normal recruitment process like everyone else!

Fun atmosphere, less stress. The atmosphere in an employer of choice is fun and thus there is less stress. As a result, employers of choice have less absenteeism because everyone wants to come to work. Managers have less stress because these top-level, loyal employees want to be there and are easier to manage because they don’t push back. Managers can coach and encourage rather than discipline and control.

This may all sound great, but there are a couple of disadvantages to being an employer of choice. First, employees of an employer of choice can be susceptible to overload and, consequently, burn out. They can love what they do so much that they can become consumed by it. But all work and no play can make your employees crash hard. Managers need to watch out for this phenomena that employers of choice can experience.

Also, employers of choice have huge targets on their backs. Competitors will relentlessly try to hire employees away from them. More often than not, however, employees working for an employer of choice will be reluctant to leave because they’re happy where they are.

Employers of choice turn the looking glass inward for starters. They also find out how they’re perceived in the community. They consider what they need to do to make their businesses attractive and what makes employees want to stay. They look at what others have done to attract and retain top-level talent and emulate them.

Shortage? What Shortage?

There’s no tech shortage, there’s just too many shops! Have you heard anyone say this? That may well be true, but beware. This is a trap that you may never find your way out of.

While it may be true that in some markets, there’s an overabundance of shops that are working at less than capacity, there are some important questions that need to be answered before we conclude that there are too many shops:

• How does this solve your shop’s short- and long-term employment needs?

• Which shops in your market are going to close their doors so you can cherry-pick their best techs from them?

• Between now and when those shops close their doors, will you have any employment needs? What if it takes a year? Five years? Ten years? What if they never close?

• Do you really want to hire someone else’s so-called “A-techs” after that someone went out of business?

• Do you understand that if you fall into the trap of thinking there are too many shops and an adequate number of techs for today’s needs that it’s only a matter of time before this strategy comes back to haunt you?

Believing that our undercapacity in some markets is the way to solving the entry-level needs of tomorrow is a dead end. In fact, taking this approach is to deny the very issue of worker shortages or, at the very least, to delay having to deal with it.

And deal with it you will. Maybe not today, next week, next month or next year. Maybe not for a few years. Still, that’s good enough for a lot of shops that will keep barging ahead and conduct business as usual until they hit the wall. These shops will end up trying to steal techs from shops that are taking this issue seriously now.

“Thanks very much for training our workers for us,” they’ll say.

Stealing techs may be harder than it seems, however. Our experience at Mentors At Work has been that most apprentices who graduate from our apprenticeship system and begin working on their own or in teams feel a certain sense of loyalty to the employers who first gave them a chance.

We constantly preach this message to apprentices: “Don’t reward the shops that weren’t willing to invest in your future.” And they listen because they appreciate that only a few shops are willing to invest in them, take the time to train them and match them up with a skilled tech who is also a trained mentor. They also appreciate the fact that following a system cuts the learning curve significantly.

Back to the so-called “strategy” of hiring techs from the overabundance of shops. How many so-called A-techs are actually A-techs? I know we call them that, or they call themselves that, but how many truly are?

Think back to when I-CAR first began to qualify welders in this industry. The failure rate was embarrassing – somewhere near 75 percent of techs who took the welding qualification test failed the first time! In the job interview, they tell you how good they are, but when they come to work for you, how many are actually anywhere near as good as they say they are?

Don’t be surprised when this issue hits your market. Don’t fall into the trap of believing that the shortage isn’t there and that the real problem is that there are just too many shops. That might work for some of you for a finite period of time, but the long-term fix for the coming shortage of skilled workers in this industry is apprenticeship systems in the shop, either in partnership with schools or not.

Return on Investment

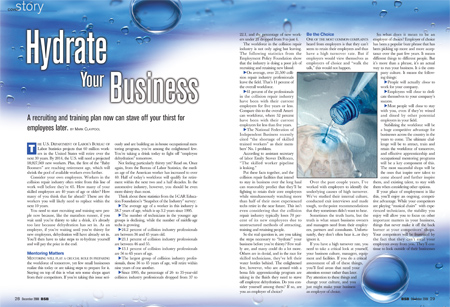

Michael Quinn, co-founder of 911 Collision Centers in Tucson, Ariz., believes that we need to get past the cost of training new people and view training them as an investment in our future. Few view it that way because it takes so much time and costs them money in the short-term. But what if we could show a long-term return on our upfront investment? Consider the following example, which is based on real-life results we’ve seen with several of our Mentors At Work clients over the past several years.

For starters, we fully expect that a new apprentice should be able to carry his or her own weight in 90 days and produce at least $40,000 of billable labor his or her first year.

In year two, apprentices should be able to continue to apply what they’ve learned in year one. They’re more efficient and learn even more new tasks that they can use. Keep in mind that much of an apprentice’s first six months is spent learning the basics, making mistakes, performing re-dos, etc. So, doubling his or her output the second year isn’t that hard when you consider that the basics have been learned and are being applied every day of year two.

We had an apprentice who came into our apprenticeship program with no prior training in school and produced outstanding productivity numbers 22 months into it. He has turned as many as 100 hours a week already in his young career. For the sake of our example, he’s neither our best apprentice nor our worst. Let’s say that his average is 80 billable hours a week. Multiply that by a suggested labor rate of $40 (for demonstration purposes only) and you get $3,200. Multiply that by 49 weeks of actual production time (taking out vacation, sick days, personal days, etc.) and you’ve got $156,800. Our apprentice was only 22 months into our apprenticeship system, yet he was already exceeding $80,000 at the end of three years.

How was this guy doing a year earlier when he was just 10 months into his apprenticeship? He was producing more than 40 hours a week, and at times, significantly more. So he exceeded our example numbers in both year one and long before the end of year two. But remember, this is only to show you that our example numbers are actually low based on a real-world experience and that your results may be different, so fill out your own chart (pg. 38).

I’m consistently asked by shop owners and managers, “What’s in it for us?” or “Why shouldn’t I just hire experienced people? Training new people costs me money, why would I want to do that?” Some of the statistics we’ve shared with you above should answer some of those questions.

The fact is, companies that intend to be in business long-term need to find the answers to these questions so they will no longer delay in doing something about the workforce of tomorrow. Delays in this realm of our businesses will actually cost us money in the long run, but too few believe that.

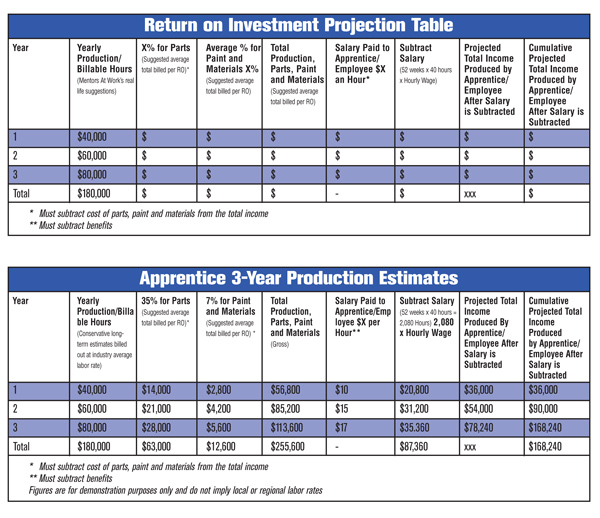

That’s why Mentors At Work has created a “Return on Investment” table that shows collision repair facilities why they need to start an occupational mentoring program (pg. 38). After plugging in your own average percentage of parts per job RO, paint and materials per job and the hourly wage you pay new apprentices, do the math and see what kind of return on investment you can expect if you follow a structured apprenticeship system.

First, we’ve provided you with an example of what a completed table looks like (pg. 34) projected at three years. Check it out and then fill in your own.

As you can see, if you handle apprentices correctly, they can make you money, not cost you money. As they become more and more proficient, apprentices produce more work faster, earn their own keep and then start adding to the bottom line.

Now, let’s figure out your own return on investment. First of all, if you follow a proven system for developing your own talent, it’s reasonable to expect a new apprentice to produce at least $40,000 worth of billable work his or her first year. So, using conservative estimates in column two, we suggest production of $40,000 the first year, $60,000 the second and $80,000 the third.

In column three of our example, we put in an average of 35 percent for parts, and in column four we put in 7 percent for paint and materials. These are added to a typical RO. So, for your shop in year one, figure out your average for each of these, multiply $40,000 by your percentage for parts, enter that number in column three, then multiply $40,000 by your percentage for paint and materials and enter that number in column four. Add columns two, three and four together and enter that number in column five. That provides you with the total an apprentice can produce in production, parts, paint and materials.

That number alone is interesting, but let’s take it one more important step. Consider what you intend to pay a new person in year one. Enter that number in column six. Multiply that hourly wage by 2,080 hours (52 weeks x 40 hours). Enter that number in column seven. Now subtract column seven from column five and enter that number in column eight. That gives you a net produced by your apprentice. Repeat these steps for years two and three.

Because benefits are so varied, they aren’t included in the return on investment table. You’ll need to subtract that from the net in column eight. You’ll also have to subtract some salary subsidizing you’re going to do early on and the short-term productivity loss of your mentor, who will be taking time to teach and train.

So, in our example, this shop has over $36,000 in income (you must still subtract the cost of parts, paint and materials, and benefits) after salary has been deducted – quite a cushion that gives the shop a strong expectation for a return on its investment. Better yet, after you project your figures for years two and three, you can see that the returns just keep on coming at a greater clip.

Even if you do lose a new employee or two while in the initial apprentice stage, you still have room to make that loss up by retaining one or two. And the longer you retain an employee who you trained from the ground up with a proven apprenticeship system, the greater the return will be on your initial investment.

After you figure out your own ROI, what should you do next? Strengthen your existing entry-level training system or start a new one. If you need help, please feel free to to contact me personally. Be proactive and you’ll be in good shape for the future.

BSB Contributing Editor Mark Claypool is the vice president of operations for VeriFacts Automotive and the founder of Mentors At Work (now a division of VeriFacts) and Select Tech Professional Services. He has 25 years of experience in the fields of workforce development, business education partnerships and apprenticeships. Claypool is the former executive director of the I-CAR Education Foundation and the National Auto Body Council (NABC). He was the national director of development for SkillsUSA/VICA and serves, on a volunteer basis, as the TeamUSA Leader for the WorldSkills Championships.