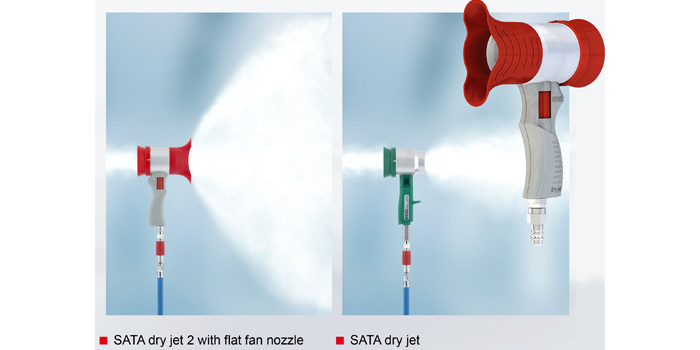

SATA has announced the unveiling of the new SATA dry jet 2. To ensure a fast drying process following the application of waterborne paint, it’s vital to apply as much air as possible within a short period of time onto the painted object. To achieve this objective, the SATA dry jet 2 also relies on the Venturi principle like its predecessor: In addition to the compressed air feeding the system, a multiple of ambient air is drawn in that serves directly to accelerate the drying process. The SATA dry jet 2 has an extra large air footprint, which further increases the drying efficiency, helping reduce the flash-off time and enhance the quality of the drying process at the same time – thus increasing profitability. The recommended inlet pressure is 29 to 35 psi and uses very low CFM of 8.2 to 9.35. With the Venturi principle design, the CFM is magnified by 10 to give a 92.35 CFM output. Due to the integrated air regulation, the painter can precisely adjust the air supply to adapt the airflow volume to ideally suit the requirements of the painted object. A painter can dry an entire side of a car with one SATA dry jet 2. An integrated 125μ sieve serves to filter contamination from the aspirated air. This disposable sieve is simply inserted prior to operating the blower gun and can be easily replaced with a new one, depending on usage and degree of contamination. Thus, the need for time-consuming cleaning of a filter element is eliminated. The SATA dry jet 2 uses the same 125μ filter as the SATA 0.3L RPS cup lids. The filters are also available separately in a 10-pack (order no. 222125). For more information, click here.