Looking back is a favorite pastime of mine, perhaps because I’m an old fart and have more to look back on than look forward to. One of the things I recalled recently was an experience I had about 20 years ago with a plasma cutter. Although I had used all sorts of cutting tools, the plasma cutter was new to me and so I needed to figure out how it worked. I remembered making some cuts and being convinced that it cut similar to a torch yet was electric.

Looking back is a favorite pastime of mine, perhaps because I’m an old fart and have more to look back on than look forward to. One of the things I recalled recently was an experience I had about 20 years ago with a plasma cutter. Although I had used all sorts of cutting tools, the plasma cutter was new to me and so I needed to figure out how it worked. I remembered making some cuts and being convinced that it cut similar to a torch yet was electric.

I had been trimming out an A pillar on a 1955 Chevrolet that I was helping a friend rebuild. The body had already been sent to be acid-dipped to rid it of all the rust, and I was at the stage where we were trimming away the jagged edges in order to plan out the restoration of the missing metal areas. As I trimmed away the excess, I thought to myself, “I know exactly how this machine works!” To cut away metal in the past, I had taken wet welding rods with an arc welder and turned up the amperage when I didn’t have a torch readily available. The arc welder left a wider cut, but I thought it was just a matter of getting the metal grounded and striking an arc on the metal at an amperage high enough to melt away the kerf. Well, as I was cutting along on the Chevy, I had a rude awakening when I looked over to find the work lead wasn’t hooked up, yet I was still cutting like a banshee screaming in the night!

“Holy mother of slag!” I thought. “Could this really be happening?” My whole theory had been blown away. As I stopped to gather my thoughts, I realized, as many of us do, that there were machines and procedures out there that I hadn’t been exposed to. That’s right – I had to dent my ego and admit that I didn’t know everything. I had certainly been ignorant about plasma cutters.

The Fourth State

I’m still a humble technician who just barely has a grasp on how plasma cutters work, but using all of my research on them back in the day combined with all I could find on them today, I should be able to share with you some insights.

The first thing I found out was that there was something called plasma that has nothing to do with blood. That’s right – “plasma cutter” isn’t just a clever name or the drink of choice for vampires. This machine produces plasma, which is also known as the fourth state of matter.

Most of us are well-versed in the other three stages of matter: solid (such as ice), liquid (such as water) and gas (such as steam). But if you’re like me, the fact that there’s a fourth stage of matter is news to you. Plasma is a very conductive gas that has been raised to an extremely high temperature, usually 30,000 degrees or more. If I understand it right, plasma is common in the universe but not so common here on earth. We can find it, however, in lightning and a low-temperature version of it in neon signs. Apparently, plasma is the norm on the sun but the exception here on our floating blue-and-green orb.

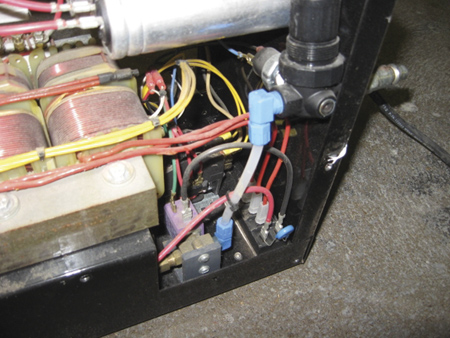

Producing plasma to cut metal involves the splitting of an atom, where the electrons separate from the nucleus and the negatively charged ones begin to move rapidly. This is accomplished by sending a pressurized gas, which could be an inert gas such as argon, nitrogen or oxygen, past a negatively charged electrode at a high rate of speed. When this reaction is achieved inside the head of the cutter, the plasma is sent at approximately 20,000 feet per second through the conductive material we’re trying to cut. Plasma will cut pretty much anything that’s conductive that allows it to become part of the circuit. In other words, it won’t cut wood or plastic, for example, because these materials aren’t conductive and thus the plasma can’t react with and pass through them.

Shopping Around

To me, all that stuff sounds like it’s from Star Wars, and I still can’t quite get all those atoms, electrons, protons and neutrons to line up in my noggin. Therefore, I’m going to head off on a little different path and provide you with some information you can actually use.

The technology in these machines is changing. Now, with inverter technology, plasma cutter manufacturers are able to make lighter, more efficient machines. Some even have compressors built into them, eliminating the need to hook up air hoses. As far as choosing the one that’s best for you, you should use the same criteria as you use when choosing other pieces of equipment. Spending too little is the worst crime because you’ll still need or want something you didn’t get and the money is gone. On the other hand, there’s no need to buy a machine that can cut 2-inch steel if all you’re ever going to use it on is sheet metal. But the same principle applies: you always get no more than you pay for, and sometimes spending more costs you less. For example, some of the cheaper machines I looked at would cost more to use because of the type of arc initiation they use. The sparks that come out of these machines have to be wearing on something; better designs concentrate on cutting metal instead of the consumables. Most companies will have a projected consumables cost to illustrate a comparison of costs between different models. But when you’re comparing different brands, keep in mind that different manufacturers use different criteria when figuring these costs. Perhaps then you can figure out if it’s worth spending more initially for a machine if the savings on the costs of consumables over time could afford you a better machine.

As a rule, a machine with higher output will give you a longer duty cycle at the lower settings, which are what body shops are most likely going to use. Consider how much time in a day you’ll be continuously using the machine. If you commonly spend two or three hours continuously cutting on floorboards for rust repair, you might want a higher duty cycle than someone who cuts off the end of a frame rail occasionally.

Also, when you’re ready to get a new plasma cutter, it’s wise to consult with the people who you’ll most likely be dealing with on a regular basis once you get one, such as the distributor of your gas bottles and welding supplies. You might even talk to the tool guys we all seem to have on a weekly payment plan. As long as you owe them, it seems like they stay interested in helping you with your needs! They can advise you on consumable costs as well as the limitations of each model they sell.

A Mysterious Beast

In order to deepen my knowledge of plasma cutters, I talked to fellow techs and even vendors who sold the units. Much to my surprise, the average person I found using or selling plasma cutters had no more of a clue than I about how they worked. The look on the face of one jobber when I told him about my experience of cutting without the ground connected was priceless. Of course, in my opinion, it’s not crucially important to understand how a plasma cutter works when you’re cutting metals, and I can’t say that learning what little I have about them has made my cuts any smoother. But I do have a bit more respect and appreciation for this mysterious beast.

I’m definitely old school as far as using new tools and changing the way I do things. But I do keep my mind open to new possibilities and occasionally try something new – as long as I’m convinced that the new way is a better one. Will I do away with the old torch and cut-off wheel and switch to plasma cutting only? Of course not. Things would be a lot more difficult for me if I didn’t have either of those tools. The plasma cutter is easy to get used to, but it shouldn’t be considered a magic cure-all as it seemed to me when I first started using one. Still, I’ll most likely keep one around as long as I’m able to work on cars, or at least until something more mind-blowing comes along. May the force be with you!

BUYING TIPS

1. Consider how much time in a day you’ll be continuously using the machine.

2. Compare costs based on projected consumables.

3. Remember the golden rule: You always get no more than you pay for, and sometimes spending more costs you less.

4. Consult with individuals such as your “tool guy” and the distributor of your gas bottles and welding supplies.

Contributing Editor Keith Combs is the body shop manager at Bill Roberts Chevrolet, where he’s been employed for more than 25 years. He was named GM/ASE Master Collision Repair/ Refinish Technician of the Year in 2000 and was one of the first to achieve GM’s World Class Technician status in 2002.