Competitive advantage comes from delivering the highest levels of quality, speed and cost performance. Developing standards, executing on those standards and continuously improving your processes is critical to achieving and maintaining that competitive advantage.

Three Objectives

Carubba Collision’s efforts relative to standard operating procedures (SOPs) are based on three objectives:

- Improving our training and coaching effectiveness and efficiency

- Improving (first-time) quality, eliminating rework, waste and relative cost

- Enabling continuous improvement

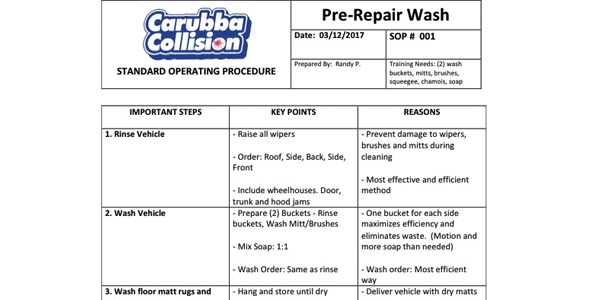

Our SOP documents are designed to support our efforts aimed at those three objectives. These documents include three columns:

- Important Steps (what to do)

- Key Points (how to do it)

- Reasons (why we do it this way)

The document is then used to guide training and coaching – where the work is being done – on the shop floor or in the office.

Continuous Improvement

Research (backed by our experience) suggests that left alone, up to 70 percent of all improvement efforts fail over time. So our managers follow up training sessions to make sure the SOP is being followed as trained and get the process back on track if necessary.

The SOP document is key to continuous improvement. Without clear and documented SOPs, trying to improve is like trying to hit a moving target.

SOPs to Consider

Here is a partial list of potential SOPs to serve as thought-starters:

- Telephone etiquette

- Answering the telephone

- Scripts

- Putting callers on hold

- Transferring calls

- Customer service

- Greeting customers

- Determining customer needs, wants and expectations

- Sales process

- Authorization to repair

- Creating the job information pack

- Hand-off to vehicle check-in

- Vehicle check-in process

- Identifying claim-related damage

- Mapping unrelated damage

- Crash wrap

- Photos

- Quality verification

- Meticulous disassembly

- Mapping authorized repairs

- Mapping supplement repairs

- Bagging hardware

- Parts cart organization

- Final blueprint and internal information pack

- Parts procurement

- Parts ordering

- Parts check-in

- Parts quality verification

- Parts mirror matching

- Parts delivery to tech

- Parts returns

- Quality verification

- Damage assessment

- Meticulous disassembly

- Body, structural, mechanical repair

- Paint prep and paint

- Assembly

- Detail

- Final quality verification

- Delivery

- Required delivery documents

- Customer take-home folder items by insurer

- Positioning of vehicle upon pick-up

- Reselling completed repair

Developing SOPs

Here are some steps for developing SOPs:

- Go to where the work is being done (on the shop floor, in the paint room, at the car wash bay, in the office, etc.).

- Observe the work being done, identifying important steps, key points and reasons why the work is done a certain way.

- Document how the work is actually being done now. This will serve as the current standard and fuel discussion around how the work should be done, creating an improvement opportunity.

- Use the SOP document to engage the people working in the process to improve the process, distribute documentation on how things are currently being done and schedule a working lunch to have a discussion around improvement opportunities. Have the meeting where the work is done, not in the lunchroom.

More Benefits

SOPs offer many benefits that go beyond the three objectives I mentioned earlier.

Good SOPs will do the following:

- Strengthen competitive advantage of quality, speed and cost performance.

- Improve training effectiveness and efficiency

- Eliminate waste and relative cost

- Reduce mistakes

- Improve (first-time) quality workmanship and customer experience

- Enable development of resources and flexibility to perform a job.

- Example: A disassembly technician calls in sick and will not be able to work for four days, leaving store “A” short in that department. Transfer to another store is easy when all disassembly technicians perform work to a standard.

- Example: A parts manager gets swamped with orders arriving, so he recruits help from a shop porter or technician to perform parts check-in, quality verification and mirror matching.

- Example: A customer service representative (CSR) is out three days while attending a training program. A CSR from another location is brought in to compensate for the CSR being away for a few days.

- Reduce workplace stress.

- Enable load leveling of people and/or jobs.

We’re Never Done

The collision industry continues to change at a rapid rate. With change comes many new and extraordinary opportunities that require us to continuously improve our processes and our systems.

Every improvement requires change, and change is always the challenge to overcome. We believe developing, executing and improving our SOPs is critical to our success today and in the future.