At one point or another, most shop owners contemplate the issue of shop layout and design. Whether the goal is to improve workflow through an existing facility, add on to an existing building or start from the ground up, all owners are anxious to reap the benefits of a well-designed facility.

Before taking on any design project, some important planning stages should be considered. A common misconception among many shop owners is that more equipment and more square footage will automatically yield more profit. While these elements can increase capacity, they simultaneously increase overhead and operating costs.

The truth of the matter is, productivity and profitability are just as much functions of management as they are functions of physical capacity. Evidence of this exists in the number of successful shops throughout the country that seemingly defy the laws of collision repair. Many of these shops are found in aging structures, which are often the result of incremental expansions that occurred with gradual business growth. Some of these buildings, which were never intended to be repair facilities, are filled with columns and are divided by load-bearing walls. Others have body shop operations isolated in multiple buildings, making the repair process seemingly disjointed. All of these buildings make unlikely homes for thriving collision repair businesses, yet that’s exactly what they are — thriving businesses.

The productivity standards against which most body shops benchmark themselves are representative of the work these shops produce on a consistent basis. How do they defy all shop layout principles yet maintain high productivity and profitability levels? They do it with sound management techniques and a thorough understanding of their businesses.

It Takes More Than Design

Savvy owners realize a good shop layout doesn’t make a shop productive, it simply makes an already productive shop more efficient. If your facility isn’t producing at a rate close to industry standards, then chances are the problem isn’t the facility layout or lack of space. It’s more likely management or personnel issues that should be resolved prior to embarking on any facility expansion project.

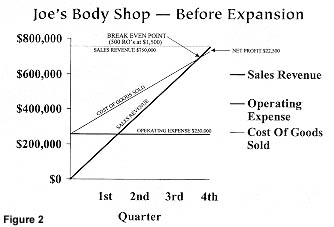

Expanding a marginally profitable business can be a less-than-rewarding proposition. A sudden increase in overhead and operating expense without an increase in cash flow can produce disastrous results. So, before proceeding with any construction plans, sit down with an accountant and prepare a detailed financial plan for the project. Consider the following hypothetical example:

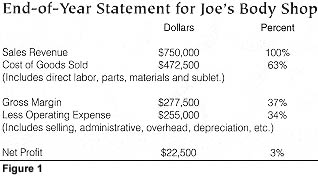

Joe’s Body Shop is 8,000 square feet in total size and employs six technicians and three office personnel. The shop’s end-of-the-year profit-and-loss statement looks as follows (see Figure 1):

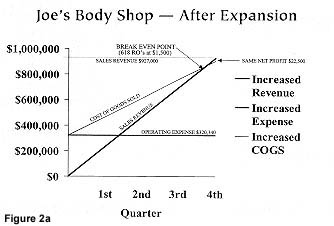

Now suppose Joe decides to expand his shop in an effort to grow his business. He decides to make his existing building strictly body shop and offices and to build a 6,000-square-foot addition to house a new paint shop that will be fully equipped with two downdraft booths, two double downdraft prep stations and a paint-mixing room. The approximate cost for this endeavor: about $240,000 (6,000 square feet x $40 per square foot in construction costs and another $150,000 in equipment). What effect will this have on the monthly operating expense?

The operating expense must be adjusted to include the monthly mortgage payment for the building of approximately $1,995 ($240,000 borrowed for 20 years at 8 percent) and the lease payment on the equipment of $3,450 (based on $150,000 at an approximate rate of $23 per $1,000 borrowed per month over five years). The operating expense for the year has now increased an estimated $65,340 (12 x [$1,995+$3,450]).

Operating at a 37 percent gross margin, this facility will have to generate an additional $177,000 in total sales just to cover the cost of the capital expenditure for the addition and the equipment. Using an average repair order of $1,500, this shop will need to process approximately 118 more jobs per year to essentially break even on this investment (see Figure 2A). Note that this example doesn’t account for other expenses that would also increase as a result of expansion, such as taxes, insurance, utilities and

maintenance.

It’s also important to realize that it may take as long as two years to ramp up production and reach full capacity after expanding or building a new collision repair facility. Many obstacles will be faced in the months following the completion of construction. Finding additional qualified, competent technicians to reach increased production levels is always difficult in the collision repair industry, and increasing the volume of work coming in the door to sustain expanded operations may also present a significant challenge.

12 Key Indicators

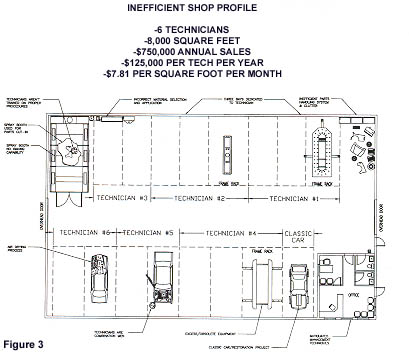

Taking a closer look at Joe’s operation, some simple figures can be analyzed to estimate the productivity of this hypothetical facility. First, the dollars per technician can be calculated by dividing the total sales by the number of technicians ($750,000 divided by six technicians). This equals approximately $125,000 per technician per year (see Figure 3).

Secondly, the dollars per square foot per month can be calculated by dividing total sales by the number of square feet and then dividing by 12 months ($750,000 divided by 8,000 square feet divided by 12 months). This equals $7.81 per square foot (see Figure 3).

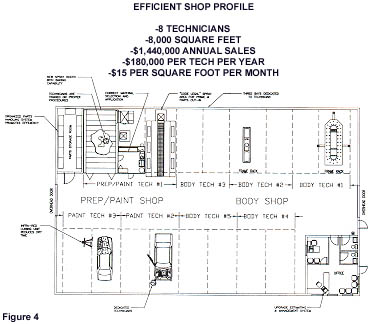

In both cases, the shop is producing well below achievable industry figures. Rapid expansion clearly isn’t the answer for this operation. Rather than expand, the owner would be wise to investigate ways to improve the flow of work and materials through the shop and to make better use of existing space and people. Following is a list of things that should be considered (see Figure 4):

1. Are more than two bays dedicated to each technician? It may be possible to add another technician if the bay-to-technician ratio is reduced to 2 to 1. This will help to increase overall production.

2. Does the shop use dedicated technicians for the repair process? Efficiency is increased when technicians can focus on doing just one part of the repair process: structural, body, prep or paint.

3. Is valuable production space being consumed by a classic car or restoration project? Freeing up this space for productive purposes can increase capacity.

4. Is the current parts-handling system efficient? Parts should be ordered and received in an organized manner to ensure technicians spend little time waiting for parts after the repair process begins.

5. Does the shop have the right amount of equipment for structural repairs? Too much equipment results in idle equipment and wasted space. Too little equipment results in a bottleneck and reduced technician efficiency.

6. Does the spraybooth have baking capability? Air drying paint jobs wastes time, space and money, and it stifles productivity.

7. Is valuable booth time being used to cut in parts and/or prime? Consider adding another “code legal” spray area for these purposes. This will free up the booth for additional topcoat applications.

8. Are portable infrared curing units being used to expedite the drying process? Reducing dry time improves throughput and technician efficiency.

9. Is the shop kept neat and clean or are parts and materials strewn about the place? Organization and cleanliness promote efficiency.

10. Are the right materials being used for the repair process? Correct selection of products can improve productivity and reduce defects and re-dos.

11. Does the shop use antiquated management techniques? Computers and information technology are revolutionizing the way progressive shop owners manage their businesses.

12. Are the technicians trained on a regular basis? Keeping technicians current on the latest repair procedures improves efficiency and employee moral.

Starting the Design Phase

Assuming the potential of your existing facility has been maximized and you’re certain expansion is the answer, you’re ready to begin the design phase of the project. When you begin this phase, it’s important to start with the end in mind. The goals of your project should’ve been accurately defined during the planning process. Unfortunately, many questions still remain unanswered, such as what’s it going to take in physical terms to reach the stated objectives? How many employees will be required? How big of a facility will be needed? What equipment will be required? These questions can sometimes be answered by the design constraints placed on the project.

Shop design projects are often limited by physical constraints. Those aimed at improving workflow in an existing building are obviously limited by the walls that surround the current business. Expansion projects may be limited by property lines or building-to-lot-size ratios. Some projects are limited by the amount of working capital available. Still others are limited by less tangible restrictions that are equally important, such as local market conditions or environmental considerations.

The Variables

In today’s collision repair industry, technicians are still the variable that can be most highly correlated to dollars. For that reason, they remain the focal point of traditional shop design and are often the starting point when defining the physical properties of a construction project. As a rule of thumb, a sales volume of $180,000 per year per productive technician can be used to quickly estimate manpower requirements.

As with any rule of thumb, this number isn’t carved in stone and can vary based on the unique aspects of an operation. Factors affecting this figure include higher/lower than average labor and material allowance, higher/lower than average parts sales (import vs. domestic, luxury vs. compact, heavy hit vs. scratch and dent). This figure is based on a technician working approximately 230 days per year (accounts for vacation and holidays), eight hours per day, at a labor rate of $32 per hour and at an efficiency level of 150 percent. This also assumes labor represents 49 percent of all sales (see Figure 5).

If, for any reason, these assumptions don’t apply to your business, be sure to make the necessary adjustments. Dividing the projected annual sales volume by this figure ($180,000) will provide an initial estimate of the number of technicians that will be required. Assuming the goal is to build a collision repair facility capable of producing annual sales of $1.8 million, the approximate number of technicians required would be 10 ($1.8 million divided by $180,000 per technician).

Having estimated the number of technicians needed, the next step is to determine the distribution of the productive work force. How many body and paint technicians will be required? The old saying, “A chain is only as strong as its weakest link,” can be applied to body shop operations. Put simply, painters can only paint what body technicians can produce and, likewise, the body technicians can only produce what the painters can paint. This is a critical balance that must be achieved to facilitate smooth workflow. In some shops, this critical balance isn’t present. Usually, it’s in the form of too many body technicians or too few preppers and painters. This inherently results in the inability to maximize production and profitability.

The best way to determine what this distribution should be for your operation is to look at the ratio of body labor sales to paint labor sales. Typically, this ratio will be about 3 to 2. This usually provides a good starting point when determining the number of body technicians and paint technicians. Referring back to the calculation that estimated the total number of technicians required for a $1.8 million dollar shop to be 10, the distribution between body and paint would be roughly six body technicians and four paint and prep.

The number of technicians can then be related to the number of work bays required in the facility. Most body shops are designed to allow for two bays per technician. While this theory hasn’t been scientifically proven, industry acceptance suggests this technician-to-bay ratio provides the best return on investment. Allocating three bays per technician may result in higher individual technician efficiencies, but it’s not typically high enough to compensate for the productivity increase that would result from adding another technician.

The approximate size of the facility can also be estimated if projected total sales have been pre-defined for the project. Using a standard figure of $15 per month per productive square foot of space, the production area can easily be calculated by dividing total sales by $15 and then again by 12 months. Using the $1.8-million shop described above, approximately 10,000 square feet of production space would be required ($1.8 million divided by $15 per square foot divided by 12 months). This figure can then be related to the total square footage.

Other non-productive areas, such as offices, parts storage and employee areas, typically make up about 25 percent of the total. Relating this to the 10,000 square feet of production space calculated above, another 3,300 square feet would be required for non-productive areas (10,000 divided by .75 = 13,333 square feet). Keep in mind that this is only a general starting point. Facility size will ultimately depend on other specific requirements.

Layout — The Most Complex Element of Design

Having estimated the number of technicians and facility size, attention can be turned to the most complex aspect of shop design — layout. Determining the size and location for various body shop operations can be a complex task due to the special requirements of each and the relationships that must exist between them. The many variables must fit together like pieces of a puzzle. And changing the size or configuration of just one piece of the puzzle often has a ripple effect that disturbs the entire layout.

Shop layout is ultimately a balance between productive work space and convenience. The most efficient use of space is simply to provide overhead doors for each work bay, thereby eliminating the need for aisles. The most convenient layout provides multiple aisles to facilitate the transition of vehicles through the various stages of the repair process. This also applies to non-productive areas where usable space is often traded for aesthetics and creature comforts.

Perhaps the best way to solve the layout dilemma is to consult with professionals who have experience with body shop design. A number of shop design consultants have emerged over the years. Some equipment manufacturers can also provide design consultation, which is extremely helpful when it comes to exact equipment specification and placement. These consultants commonly focus on a specific area: frame equipment manufacturers focus on the body shop, spraybooth manufacturers focus on the paint shop, etc. Many paint manufacturers also offer design assistance and provide a complete in-house planning service.

Some independent design consultants have also emerged who specialize in body shop design and construction. These independents can typically provide a large range of services, although they usually come at a higher cost than the manufacturers. (Note that a shop design consultant isn’t usually a substitute for a licensed architect. When selecting an architect, try to find one who has previous experience in the collision repair industry or at least a basic understanding of the business.)

Working Designs

Following this basic model and answering the questions outlined will enable you to make informed decisions regarding the renovation, expansion or construction of a collision repair facility. If it’s possible, get out and see what others have done and learn from their successes — as well as their mistakes.

For many, expanding or building is a once-in-a-lifetime opportunity. And since you only get one chance to do it right, take the time beforehand to prepare so you won’t have to learn from your mistakes later.

Writer Randy Slama is a Sherwin-Williams Automotive Finishes design engineer.