By now, we’ve all heard about aluminum repair and the cost of training and equipment. You all have your opinions on how feasible and viable it is. Many are evaluating whether it’s worth the money and time. I can’t answer these questions for you, since the variables are across the board. People tell me all the time that “It’s not hard, just different” does not apply. And I’m here to tell you it’s not hard, but it is different. Very different.

Equipment and Training

Yes, there is the cost of equipment. We’ve all heard the stories about how much shops have spent. I’ve also seen shops that achieved the requirements very economically. It all depends on your research into the tools and what abilities you want your shops to have.

Then, you have to consider training for your technicians, which I-CAR can offer. After that, it’s learning the process and tools needed to do the repair.

What I just described is what we all went through to learn how to repair the newer steels, along with plastics. The industry is evolving and changing. We’ve evolved and changed before, and we’ll keep doing so. Your competitor is.

Should It Be Repaired?

As vehicles evolve and the repair of vehicles changes, we need to evolve and change too. I recently visited a friend’s shop and the manager was asking if he thought the hood could be repaired. It was made of aluminum. I examined it and basically said anything can be repaired, but should it? How much time and cost are you willing to put into a repair? He thought it was worth the time.

I was there doing a welding test and started to do my I-CAR thing. Awhile later, the manager came up and said the repair did not work. Why not, I asked. He said the tech stretched the metal out too far in trying to repair it. I went to take a look and thought, holy Hannah! What did he do? I asked him what he had done to remove the damage, and his reply disappointed me, to say the least. I asked him if he had taken any aluminum repair training, and he said yes. I asked how long ago, and he said last year.

Practice Makes Perfect

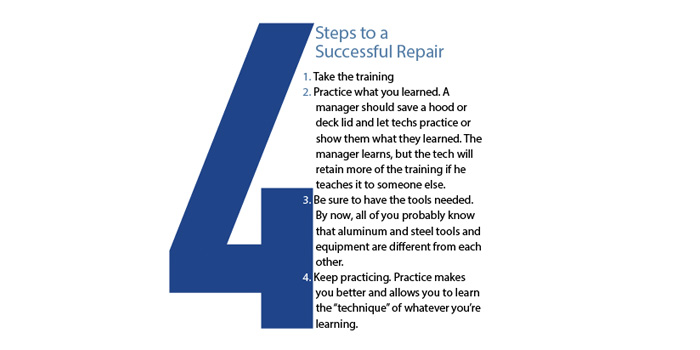

You can learn a lot about aluminum repair by taking classes, but then you need to apply and practice those skills before you forget what was learned. This is a major problem in our industry. We take classes, but we don’t practice and apply what we learn hands-on. This why the I-CAR welding and MIG brazing classes are so important. They teach not only background but hands-on skills.

In my opinion, the tech at my friend’s shop was set up for failure. Now he has lost respect for management and has no desire to try this kind of repair again. Nobody likes to fail. If he had practiced or taken hands-on training after classes, he would have had at least a chance to succeed.

Succeeding with Aluminum

We’ve been working with steels for so long that we may not even think about the procedures we take to repair them as they’ve become second nature to us. Aluminum has some differences, though. If we do not consider these, we set ourselves up for failure.

Just as there are different grades or strengths of steels, there are different grades or strengths of aluminum. Knowing the strength of the aluminum is critical to determining how much repair time will be involved. Since this can be a major factor also in whether we repair or replace the panel in question, it seems a good place to start.

Knowing the series of aluminum and alloys is step one. The correct wire is critical to successfully welding tears or attaching panels. Vehicle manufacturer websites and ALLDATA are good sources of material and repair requirements.

Knowing the temper is also a factor since it directly correlates to repair time. Aluminum with a high temper such as T6 reacts like ultra high-strength steel. It’s very strong but also brittle and prone to cracking. This will involve more time versus repairing aluminum with a lower temper such as T0 that’s soft and malleable. We’ve seen most automotive applications to be T4, with some being T5.

I want to say this as a separate statement to be sure there is no confusion: Aluminum is not difficult, it’s different. Very different. It’s also time consuming to repair.

The higher temper – if it did not crack during the collision – can be difficult to re-form. We are not repairing damage, we are re-forming a panel. This will take time. The lack of memory in aluminum requires a different approach than steel.

Knowing the series and temper will give a starting point to understand how to proceed, if possible.

Damage

Like any material, there is a limit to what can be repaired correctly and economically. Aluminum hardens as it’s worked or formed. Most parts will be labeled “heat-treated aluminum.” The other classification, “non-heat treated,” is a manufacturing term meaning that the aluminum was heated to shape or form. The heat makes aluminum more malleable and easier to form without cracking. The interesting point is that during all panel repairs, the technician can or will use heat regardless of designation.

The work hardening also occurs during damage. This will make damaged aluminum stronger than surrounding material that is not damaged.

Highly formed areas in aluminum like steel will be difficult to repair. The body lines and forms are there as stiffeners for strength and can be very difficult to re-form. Even when heated, aluminum can be difficult to form.

Watch the Heat

Heat must be used in a controlled manner. Depending on the manufacturer, heat can be applied for as long as needed, and multiple times. The one rule that must be followed is not to exceed the manufacturer’s limit in any area or area of repair. Most will be between 400 to 570 degrees. Once you hit the upper limit, the aluminum will be permanently softened, rendering it junk. Using heat crayons or a non-contact thermometer setup for aluminum is best. Non-contact thermometers can sometimes be inaccurate on highly reflective surfaces such as bare aluminum. Emissivity would require changing the surface or tool to read accurately. Again, this is where the training classes work, as these issues and procedures are discussed in all I-CAR aluminum training classes.

Aluminum also has a high degree of radiant flow. This means that heat will radiate out very quickly from the repair area to the whole panel. Thus, foams and sealers will be affected. Using heat effectively and keeping it in the repair zone is critical.

Relieving Stress

Hammer “off dolly” for stress relieving is the best technique to avoid stretching aluminum. Slapping spoons and other techniques are also good ways to relieve stress and not damage the metal. Using a hammer and dolly or stud tools such as aluminum dent removal tools comes down to personal preference. Everyone has different success with different tools.

General Process

OK, so after reaching series and temper and manufacturer requirements, you’ve decided to proceed. The next steps include:

- Evaluate the technique you want to use. Disconnect battery and any other electronics in the repair area.

- Apply heat with your source of choice. Heat up the damaged area. It will start changing right away as stress is released. Monitor the heat and the radiating heat outward. Let it cool and see where the damage changes. If heat radiating out is an issue, use air or a wet rag to cool. Note: aluminum does not change color with heat. Using 80 grit or higher, remove the coatings for attaching studs. Follow equipment manufacturer’s procedures. They’re all fairly similar, but some are a little different. Practice on similar or same panels before ever working on the vehicle. Practice putting studs on a damaged panel area to prevent settings that could blow a hole in the metal. This is kind of like doing a practice weld. Keep in mind also that ground can be sensitive.

- Apply studs. Depending on the dent and body lines. Align pulling tool.

- Apply heat to recommended temperature and apply pressure on bar to pull studs. Once to desired area, stress relieve the surrounding area as the metal cools. Repeat or move as needed. This will take time. When removing studs, cut leaving base then grind off using 80 grit. This will help prevent pulling material or making holes. Don’t twist.

- Refinish similar to steel procedures.

Summary

One of the major points is that we’ve been getting away from heat in steel repairs. Aluminum, however, will need heat – controlled heat.

This article has just gone over the basics. For most of you, it hopefully will have served as a refresher. Repairing aluminum will take practice, and technicians will see best practices as they use these procedures. When you look at the pile of aluminum in the back of the shop, think about how much labor could be laying there.