Five years ago, a shop owner purchased four acres of land with the dream of someday building the perfect collision repair center.

Someday came.

For the past six months, he’s been working with facility designers, architects and bankers, getting his ideas on paper and making sure his banker will back this venture for him. At this point, he’s probably spent hundreds of thousands of dollars for the land, and several thousand dollars for the designer and architects. Not to mention all the time he’s put into the project.

But that’s OK. After all, it’s his dream.

Next on his list of things to do, he goes to the courthouse to get his building permit. There he finds out his county passed a land-usage ordinance three years ago, and his proposed facility will require a minimum of six acres of land.

It gets worse. His property is landlocked by neighbors who refuse to sell him any of their land at any price. Furthermore, even if he could get the additional property he needs, the county is going to require him to put in a ground water-entrapment system with a stand-alone filtration plant to filter any runoff water before it drains from his property.

His dream has turned into a nightmare.

If this scenario sounds scary, imagine having to live through it. I’ve been designing auto repair facilities for years, and I have enough nightmare stories to make an owner want to rent his facility forever. Like the time in Alabama when we were building a facility on a piece of property with a 1-foot-deep by 1-foot-wide stream running through the back of it. We planned to put in a 2-foot concrete pipe to cover it up, but the county inspector decided an 8-foot concrete pipe would be better — making the cost to satisfy the inspection nearly $1 million. At this point, the shop owner abandoned the project, even though he’d already made more than $100,000 in property improvements (moving dirt, pouring foundation, etc.). It took him six years to sell the property at a break-even.

Want more? Another time, we were called in to consult on a project after the shop owner had designed and built a facility with 8-foot-wide doors and 9-foot-wide stalls. What was the big deal? Some vehicles won’t clear an 8-foot opening without touching on both sides.

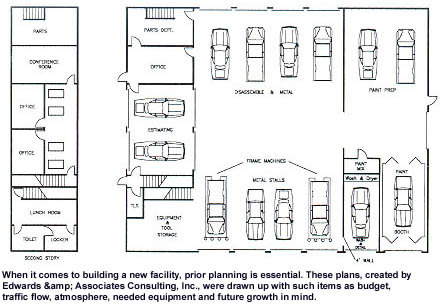

I’m not telling you these stories to scare you away from designing and building your own facility. What I am trying to do is point out that prior planning is a necessary ingredient to the successful completion of any building project. Also, please understand that just because you’re the world’s most successful collision repair shop operator doesn’t mean you’ll be the world’s most successful facility designer. I’ve seen shop owners lose more money on a new facility in one day than they’ve been able to make in a lifetime.

Undoubtedly, prior planning is essential. But what sort of planning? Let’s take a look at some of the key ingredients of a good facility development plan.

The Budget

First, establish a budget. The process of establishing a budget helps you look at all of the variables that make up the plan. Your budget should include land, facility, equipment and down time. Seldom ever does a new facility come in as planned.

If you’re leasing now, can you get a month by month extension? What will it cost you to stop all sales and production for five days to move? These items should be considered in your budget.

Several methods can be used to establish a budget. Some to consider include finished cost per square foot, monthly rent, depreciated cost, comparable rent, comparable investment and the value depressant effect of a single-use facility. Many of these terms are self-explanatory, but let’s look at a few of them in depth.

• Finished cost per square foot looks at:

Land cost

+ Land improvements

+ Building cost

+ Office cost

= Total cost

Divided by square footage of facility

= Finished cost per square foot.

Note: This formula doesn’t take into effect equipment cost and/or down time. These must be factored into your budget separately.

• Depreciated cost takes into account two monthly cost factors: interest expense on the loan (a tax-deductible item) and depreciated expense on the facility (a non-tax-deductible item).

When calculating depreciated cost, here’s what you want to know: How much you’ll have to pay monthly, how much of that payment can be deducted from operating expenses and where the difference will come from.

Ideally, you could own the facility and rent it back to your collision business. But this leads your bankers to another question: If the business doesn’t survive, does the building have multiple-use rental abilities? They must factor this in because it stands to reason that if you can’t make a go of this business, then probably no one else can either. You should also make sure you’re not building a monument to yourself, but rather a facility that will bring a return on your investment.

Once you know your total costs by establishing your budget and know how you’re going to pay for it using depreciated cost or by renting it, then you need to calculate your financial return on this investment. Calculating your return tells you whether to build a new facility or to keep your present facility and invest your profits into something with a better return.

• Comparable investment for owner-supplied facilities formula:

Annual rent

– Taxes and maintenance

= Annual income

Divided by facility cost

= Percentage of annual return on investment.

I can’t offer you any examples of what a good return is because you have to make this decision yourself by asking: Should I invest my current collision repair shop’s earnings in this facility for ____ % of annual return, or should I invest my money somewhere else for ____ % return?

Three Items of Impact

When preparing your budget, three items will have the greatest impact on your ultimate facility costs:

1. Production Methods

— conventional shop;

— support-group shop;

— team shop;

— assembly-line shop.

2. Type of Building

— drive through;

— drive-in stalls;

— combination.

3. Building Codes

— organizations that impose restrictions: lenders, insurers, fire department, others.

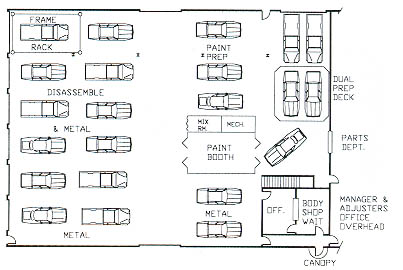

1. Production methods. Each type of production method utilizes different stall-to-technician ratios. Conventional production methods require two or more stalls for each technician, team production systems can employ one-and-one-half technicians per stall and assembly-line shops can employ as many as three technicians per stall. The type of production method you employ will ultimately dictate how many stalls will be required.

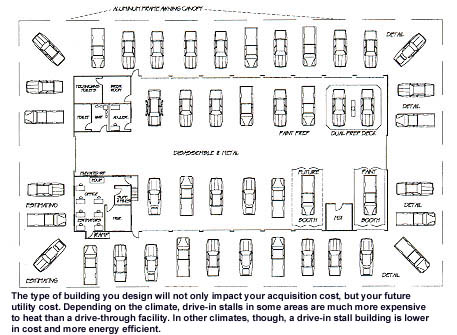

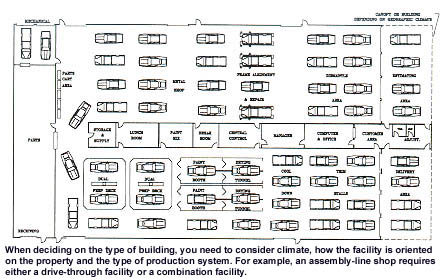

2. Type of building. The type of building you design will not only impact your acquisition cost, but your future utility cost. Drive-through buildings generally have more upfront costs because they have to be wider (15 to 30 feet) than buildings with drive-in stalls. Depending on the climate, drive-in stalls in some areas are much more expensive to heat than a drive-through facility and, over time, maintaining those overhead doors can get expensive. In some climates, though, a drive-in stall building is lower in cost and more energy efficient.

When deciding on the type of building, you need to consider climate, how the facility is oriented on the property (north, south, east or west) and the type of production system. For example, an assembly-line shop requires either a drive-through facility or a combination facility.

3. Building codes. Building codes are where we encounter the most difficulty in meeting projected budgets. And it’s not just the various government building inspectors I’m referring to. Bankers, insurers, fire departments and many other agencies also have the ability to impose restrictions on your building plans — restrictions that can cost you thousands in unforeseen costs. For example, recently we were completing a new facility in Florida. The building was finished, the lot was paved and fences were installed. The owners were already installing the furniture and computers in preparation for their grand opening when the fire department came by for its final inspection. What did the final inspection consist of? The fire department decided to bring its largest ladder truck (for a one-story collision shop) and a crew of eight firemen to do a familiarization with the building. But when they tried to pull this gigantic truck around behind the building, they discovered that because of the tight alleyway along the side of the building, they couldn’t turn the truck into the fenced-in area. Before they would sign off on the project, they required our customer to take down the new fence and relocate it with two additional gates — at a cost of nearly $10,000.

The moral of this story? Before you complete your budget, make sure you have your plans thoroughly reviewed by everyone involved so you aren’t hit with a major un-budgeted expenditure halfway through your project.

Assessing Your Current Shop

Prior to designing a new facility, we like to perform an assessment of a shop owner’s current facilities. This analysis helps establish a baseline of items we can compare to the new facility to determine the differences of the new and the old. Here’s what we look at:

• Understand and list the current facility’s strengths and weaknesses. Before we begin designing a new facility, it helps to list the strengths and weaknesses of the current facility. Then we compare the lists to our new facility’s final design to ensure we’ve incorporated all the strengths and corrected all the weaknesses.

We prepare a list of factors to be considered, and these factors determine all the basic facts about the present facility:

• Rent per square foot;

• Sales per square foot;

• Flag (billed) hours produced per square foot;

• Utilities cost per square foot;

• Storage parking spaces to productive stalls;

• Customer parking spaces to productive stalls;

• Employee parking spaces to productive stalls.

Your New Facility

Designing the perfect facility requires a lot of planning. The following is an outline of items you should consider:

• Clear, concise goals;

• Low-rent factor;

• Highly proficient production area;

• Economically sound project;

• Eye-appealing layout;

• Room for growth;

• What’s at stake;

• Traffic flow;

• Getting customers in and out safely;

• Lot marked clearly with directional and safety signs;

• Parking;

• Easy access;

• Maneuverability;

• Security;

• Customer reception/lounge area;

• Exterior;

• Interior;

• Amount of room;

• Atmosphere;

• General offices;

• Space for growth;

• Access to other areas;

• Shop/technician/parts/paint areas;

• Various processes that will occur;

• Which production concept you’ll use;

• Access to other areas;

• Needed equipment.

Getting Started

>Where do you go from here? For most shop owners, the next step is to hire a professional facility designer to help design the new facility. Granted, some shop owners have successfully planned their own facilities, but they are, most definitely, the exception. The majority of shop owners would be wise to spend the money on a designer because, in the long run, the designer will cost less than all the mistakes a shop owner will make going it alone.

What is a facility designer?

Facility designers aren’t necessarily architects. They’re individuals who specialize in designing collision repair shops. A truly professional designer will have planned hundreds of facilities and will help you commit your ideas to paper and address all the items discussed in this article. A designer will also provide you with a site plan you can take to an architect to develop architectural plans for your new shop.

Overwhelmed yet? Then you’re one step closer to understanding what it’s truly like to plan a new facility. Without a doubt, it’s a lot of work — mostly leg work. But if you plan the way this article recommends, you’re also one step closer to completing a facility that you’ll be proud to put your name on.

Writer Larry Edwards, CMC, is president of Edwards & Associates Consulting, Inc., in Charlotte, N.C., which specializes in collision shop management consulting and has a facility design and layout group that’s been designing service repair facilities for more than 25 years. Edwards & Associates can be reached at (800) 979-9904.