Every time I read industry trade magazines, I can’t help but think we’re missing the boat. Articles seem to be focused on things like improving your margins, adding new revenue sources, learning new repair techniques or getting paid more through better estimating practices. Occasionally you find some good information, but no one seems to be talking about the real problems and offering real solutions.

As a former national operations director for one of the largest collision repair chains in the United States, I’ve had the unique opportunity to work toward building a better collision repair business on a large scale. I’ve also had the unique opportunity to work with professionals from outside our industry — professionals who bring a unique perspective to business problems and solutions without being attached to the emotional “status quo,” which keeps most body shop professionals from ever changing.

Because of these opportunities, I’ve developed a different understanding of what’s really wrong with the collision repair business, as well as new solutions. Here’s the world as I see it …

1. The customer and his needs have changed.

If you look at how body shops operate (I mean the process of running a body shop that we all use), you’ll recognize that it’s virtually the same as it was 50 years ago.

Technicians are basically subcontractors inside our business. They bring their own tools and control the direction of the repair, as well as the quality and time it takes. We feed them work and do our best to manage the customer and workload.

This process of operating shops used to deliver good results when customer expectations were lower. Let’s face it. It wasn’t too long ago when customers were satisfied if they just weren’t bitten by the shop dog, or they didn’t have to pay the deductible.

Customers came to your shop usually through a referral by a friend or family member. Customer-pay work was at a much higher percentage, and negotiating with insurers was a completely different game.

Today, expectations are much different. Insurers foot the largest percentage of the bill. And they, as any other business owners, are focused on their own profitability and costs.

In the old days, claims departments were managed by individuals who had come up through the ranks — probably former technicians or shop owners who were now in charge of handling the dirty, unwanted process of dealing with body shops. Today, claims departments are run by young MBAs and executives with stock options and a vested interest in delivering corporate objectives.

Insurers now have the ability to direct a majority of all work to you or your competition, as well as dictate the price they’ll pay for repairs.

You can deny this, fight it, attempt litigation, kick, scream, “educate drivers,” call your congressman, whatever …

But the reality is that the customer is now as much the insurer as the vehicle owner. And this customer wants from the collision repair industry what all customers want from any business: They want the best price and the best quality, and they want it done quickly. Better, cheaper, faster …

2. You must give customers what they want or someone else will.

Knowing that the customer is as much the insurer as the vehicle driver, you must take a look at your business and ask:

- Am I delivering to customers what they want?

- Does the current process of operating collision repair shops deliver the results that customers seek?

- Is it possible to deliver to customers our services at the price they’re willing to pay, with the speed and quality they seek?

- Can I deliver these results and make a profit?

The answer in most cases is no.

shops was built to serve the needs of customers 50-plus years ago. It’s

not built to deliver low cost. It’s not built to deliver speed. It’s not built to deliver predictability — yet, we still use it.

The real reason we’re in this shape, as an industry, is that the current process we use to operate collision shops was built to serve the needs of customers 50-plus years ago. It’s virtually the same systems with some fancy new equipment.

It’s not built to deliver low cost. It’s not built to deliver speed. It’s not built to deliver predictability — yet, we still use it. But if your business isn’t delivering to customers what it is they desire today, you won’t be in business for long.

These shifts in the market happen to all industries, all the time. Some industries have tried to pull together and fight the change by refusing to deliver. This never works and, in most cases, is illegal. Sometimes the customer goes overseas to find these goods and services. And sometimes, a “disruptive innovator” appears and says, “ If I know what the market has to bear, and I know what they’re willing to pay, I can create a profitable way to deliver to them what they want.”

Companies like Southwest Airlines, Toyota and Dell are good examples of companies that found themselves in an industry where the customer demanded something different. They responded by completely rebuilding themselves with the customer in mind, and today, they dominate their segments.

3. You must redesign the process of operating your shop. Rebuild yourself.

You can fight the customer (not a good idea). Or you can change to meet their needs today, while creating profit and value for your business and employees.

I will tell you. This isn’t easy, but it’s also not impossible.

We’re lucky that other people in other industries have had to deal with these shifts in the market, and that proven, documented examples of their work exists. I was fortunate enough to work with some of these people in the past and to have their help in applying these improvement principles to the collision repair business.

I can tell you that it is possible to deliver everything a customer wants and to not simply maintain your profitability — but to greatly increase it.

Since 1999, I’ve studied the path Toyota has taken over the last 50-plus years. While many components of the Toyota Production System (TPS) are recognized as improvement tools — Just in Time Production (JIT), Total Quality Management (TQM), Theory Of Constraints (TOC), Six Sigma, etc. — we’ve proven that TPS has a practical application in collision repair.

These are the kind of solutions our industry needs to be discussing. The problem needs to be addressed at its core. You must look at solutions that deal with the root cause.

TPS gets to the root of the problem.

How does TPS or “lean manufacturing” work? The purpose of TPS is to create sustainable profitability in your business while delivering to the customer the highest levels of quality, service and speed, at a lower cost (which is what the customer wants). It’s a system that recognizes that the market will continue to change and creates awareness to changes, as well as the flexibility to respond. It’s also a process of continual improvement, which will always keep you ahead of the competition.

The goal of any business should be to make money (profit) and to do it in a way that’s honorable (delivers good things to the customer, the employees and the community) and sustainable (will be around long after you’re gone).

But if you’re going to make more money, you only have a couple of choices. You either can move more cash through your business with the same amount of resources (fix more cars with the same cost) or you can reduce your cost while moving the same amount of cash through the business (fix the same amount with less cost). You must do one or the other to make more money, but you cannot forget the honorable or sustainable part.

TPS creates a process that delivers all these things.

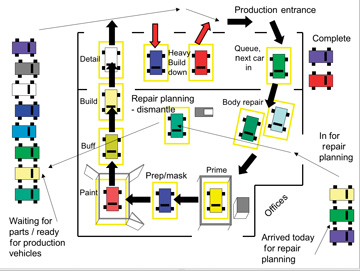

TPS works by thoroughly thinking through your current business model and identifying all the things you currently do that don’t serve to deliver (waste) to customers what they want. It then creates a single process in your business that takes your product or service, uninterrupted, from first step (sales and scheduling) to last (payment and job closing) to completion.

And each step is performed in a specific, documented way that’s been designed so that it can be done exactly right the first time — with the least amount of effort.

It’s not as difficult to make these changes as you might think, but it does require courage and support from someone who’s been through it.

Living Proof

There aren’t a lot of shops out there today that are pulling down the cash they used to. Market studies have shown that the profitability of body shops has decreased each year. Some insurers show that their severity also has decreased each year. And more administrative work and costs have been shifted to collision

repairers.

It’s not a pretty picture. Costs rising, sale price decreasing.

It’s not an impossible situation, but dramatic improvement is required. And dramatic improvement requires dramatic change.

We have made these dramatic changes and know that you can thrive in this environment.

The issues discussed today are merely band-aids. It’s important that we as an industry help each other and share our successes, or things will continue to worsen.

Vehicles will still need to be repaired, and the wrecks won’t be shipped to China or Mexico. Someone who has the financial staying power and smarts will move in and dominate this industry.

Don’t be the small hardware store watching Home Depot being built down the street.

We’re currently building a network of collision shops using these principles and would be happy to share our information with you. I believe a lot of shops are looking for answers like these.

Writer John Sweigart is a principal partner in The Body Shop @ (www.thebodyshop-at.com). Along with his partner, Brad Sullivan, they own and operate collision repair shops inside of new car dealerships, as well as consult to the industry. Sweigart has spent 21 years in the collision repair industry and has done everything from being an independent shop owner to a dealership shop manager to a store, regional and, ultimately, national director of operations for Sterling Collision Centers. Both Sweigart and Sullivan have worked closely with former manufacturing executives from Federal-Mogul, Morton Thiokol and Pratt & Whitney in understanding and implementing the principals of the Toyota production system.

|

Benefits of Lean Manufacturing in Collision Repair

• The quality of the product greatly increases because defects in the work cannot be passed along through the process or the entire system shuts down. • It’s a simple system that requires very little management intervention. People inside the process know exactly what to do, how and when to do it, and where it goes when complete. The entire process is represented visually in your business so that how the process works as well as the current status of the process or any component are known to anyone and everyone. • The entire business is incredibly clean and organized, and maintaining this is built into the process. • The time it takes to perform the work is reduced to a fraction of the time it took initially. In this system, all work moves along at a specific pace. Determining when work will be complete is as simple as understanding when work will start. The total efficiency of the process is increased by a multiple, allowing you to produce much more work with the same amount of resources. • Because work moves one at a time, from step to step, you wind up needing less space to perform more work, as well as less equipment. • The number of total people required to produce work, both direct labor and overhead, is greatly reduced. • Problems that occur in the system are quickly identified, resolved and documented without management intervention. These problems or work stoppages are reviewed periodically to identify process constraints or design issues, and improvements are made to the process to eliminate these issues. • The end result is that you now have a very inexpensive system for operating your business that delivers high-quality repairs quickly. |