The Bureau of Automotive Repair (BAR) has proposed a rewrite of California’s code of regulations on body shop equipment.

Current California code requires any body shop that uses paint to have all the necessary equipment and reference manuals for the repairs. In addition, shops that perform structural repairs must have all the necessary repair, measuring, testing and current reference manuals to diagnose, section, replace and repair the damage.

The proposed revision would require all body shops to have the required equipment and current reference manuals for the types of vehicles being repaired. In addition, the proposition would stress OEM specifications and add that all repairs must be made to vehicle manufacturer specifications.

During a workshop, Mark Guess of the BAR said that repairers who can’t meet this rule in-house could fulfill the requirements by means of subletting.

During the workshop, Guess argued that because repair procedures are getting so specific, the provisions to the regulation are needed. But BAR Advisory Group member Jack Molodanof (California Autobody Association) suggested that the language didn’t allow shops any flexibility. He said shops need such flexibility in order to perform a repair in situations where OEM procedures don’t exist. Guess replied that he was leaning toward clarification that the regulation referred to necessary shop equipment.

In addition, the BAR also included language in the proposal that would:

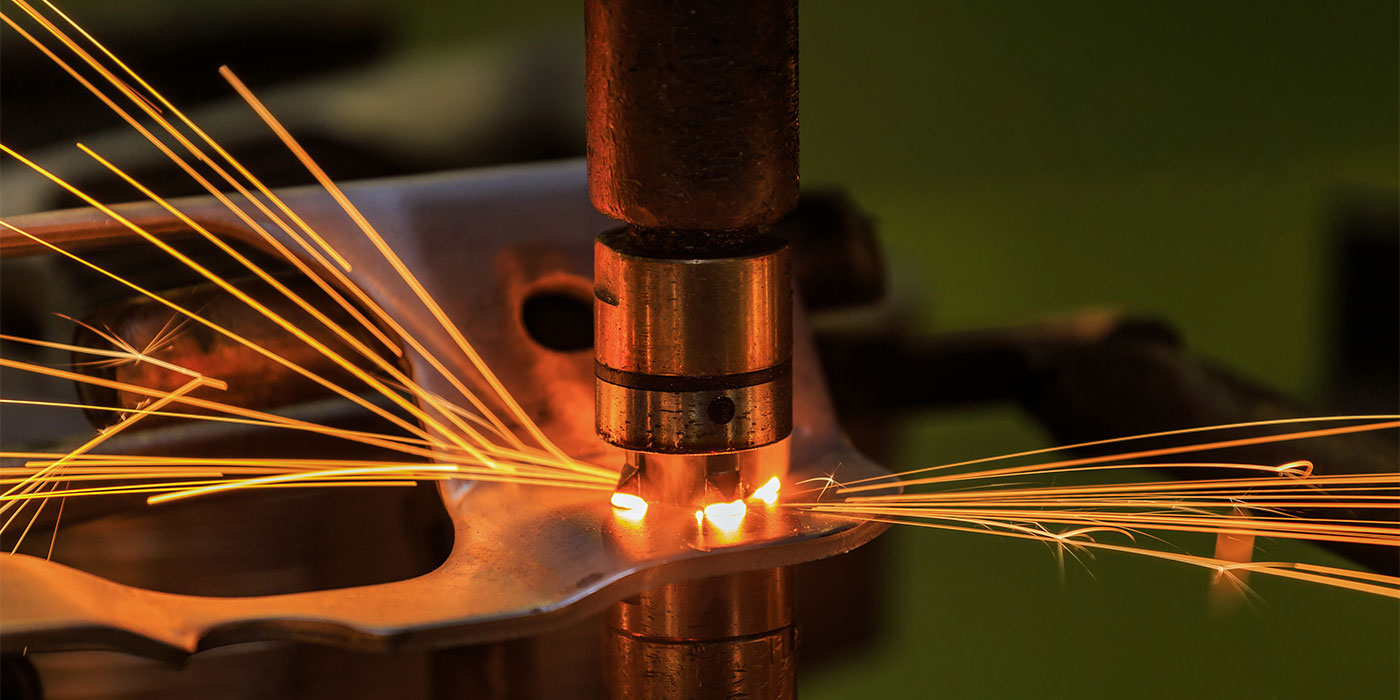

- Require shops performing structural repairs to have the proper welding and panel bonding equipment for the types of vehicle being repaired (rather than a specific welder class; this would be broad enough to include equipment needed for aluminum and carbon fiber as well as proper rivets needed).

- Allow repairers to use devices other than “flexible and rigid wands” and “spray heads” for corrosion protection. Under the proposal, any device which accomplishes the same spray patterns and coverage described in the law would be acceptable.

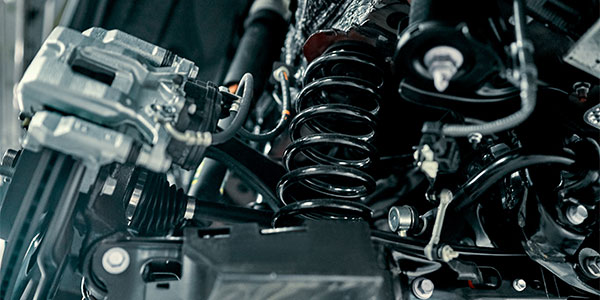

- Require a three-dimensional measuring system that records length, width and height relative to “centerline, body zero, and datum plane” (instead of “three defined reference planes”)

- Require a shop’s four-point anchoring system to be located in the vehicle center section, and that pulling equipment is able to make multi-directional pulls simultaneously. The equipment is also required to generate enough pull force to realign the vehicle structure to manufacturer specifications.