I recently researched scan tools and found there really is a lot you need to know about what you’re required to do and what you need to do about it. What’s the best way to handle scanning, purchasing a scan tool or subletting your scanning or recalibration? I wish there was one plan or program that fits all, but there isn’t.

So what can you do? Let’s take a look at wants and needs. What do you want to do and what do you need to do? There is a difference. And usually somewhere in between is the best choice.

Thank You, I-CAR!

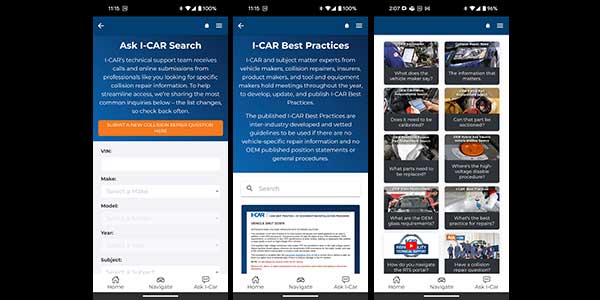

The first thing I want to do is thank I-CAR for being proactive and on track on pre-scan, post-scan and recalibrations. The new RTS website chock full of information should be appreciated by everyone in the industry. It has links to great articles to help you understand what’s changing and how much more we’ll see. Scanning and recalibrations is not going away; if anything, it will be more involved in the future.

Knowing the Difference

It’s critical to this process that we recognize the differences between pre-scan, post-scan and recalibrations. I’ve seen many companies scan a vehicle’s electronics when a recalibration was required. This can lead to serious liability for a shop and danger to the vehicle driver.

A pre-scan tells us what was damaged or what codes were set prior to or during collision, which helps to determine what is collision-related or not.

A post-scan tells us the same as a pre-scan if it was not cleared. The post-scan will also tell us what was set as codes during the repair of the vehicle. Shops working with all the new electronics will set codes on tasks as simple as disconnecting the battery. This will be the new norm as all functions will be monitored. A post-scan will tell us whether all the electronics are functioning correctly as far as connections and computer function.

Recalibrations determine if cameras or sensors are aimed and performing as required. A scan can tell you a sensor works, whereas a recalibration can indicate that the bracket the sensor is mounted to is bent. Recalibration is needed for many repair procedures, particularly on active control systems. Many bumper R&I’s and/or repairs along with windshield R&I’s or windshield replacements will require recalibrations.

What’s at Stake?

Why is there so much focus on these issues? It all comes down to the fact that vehicles are doing more for driving and stopping than ever before. Most of the issues relate to autonomous driving features in vehicles such as advanced driver assist systems (ADAS). The ADAS features offer collision avoidance options in vehicles.

There are two systems to think about:

Passive systems. These are electronics and systems that monitor and warn the driver of issues or environmental dangers such as blind spot or lane departure. These passive systems use lights, tones and maybe vibrations in the seat and steering wheel. They only warn drivers of dangers or concerns while driving.

Active control. These features and systems do much more. They still do all that passive systems do, but they can assist or take control of the vehicle in a collision or encounter with a pedestrian.

What You Want

You want to be a one-stop shop and be able to do all services in-house, limit supplements and keep your cycle time low. You can have it all, but it depends on how much you want to spend. It will take a long time to see any return on your investment, but maybe you will. The fact is there is no one scan tool or recalibration tool that will do it all.

If you wanted to do it all, you would need to buy the vehicle manufacturers’ systems individually. That is a considerable expense, and these systems would need to be updated every year. Even the scan tool services that offer to scan remotely using manufacturer software are limited when it comes to scans and recalibrations. Verifying all aspects required for a scan or recalibration may require someone who knows how to perform the procedure or is present to make sure all parameters are correct.

What You Need

Not properly repairing and verifying that systems are operational can lead to a disaster for the vehicle driver or owner. This liability to a shop and its employees is not to be taken lightly.

So what do you need? The need I’m referring to is, what ability do you need? The first ability is to find information on what needs to be done during scanning or recalibrating on repairs performed. This is where the I-CAR RTS website comes in. If your estimating software doesn’t have any information and you don’t have ALLDATA, the I-CAR RTS site is a fabulous resource for the information.

So now we’ve established that you’ll be doing scans on almost all new vehicles coming out in the coming years. Now let’s look at another point. Recalibrations require a little more of a learning curve, as these may require a static test that can be done in-shop using targets and external points. They may also require a dynamic test, which involves one to two people taking a vehicle for a drive. Depending on conditions, this could take up to 50 miles. You must communicate this to the customer as they check the odometer and fuel. Not all procedures require recalibrations, but many do.

Once you know you need to be able to scan and/or recalibrate, what do you do? You can go out and buy a great scan tool, but which one? You need to ask yourself some questions before getting one:

- What percentage of your business do newer vehicles comprise? What percentage are brand-new or within 12 months of their release date?

- Is there a predominance of one manufacturer or another? For example, do GM vehicles comprise 40 percent of your shop’s work?

- Is your shop located near dealerships?

- Is there a mobile service in your area?

- Do you have a person who can do these procedures?

- Do you do windshields?

- Do you do plastic repair?

- Do you do suspension and alignments?

- How much space do you have?

- How do you staff for this?

Why am I asking about newer vehicles? When new vehicles come out, the dealerships receive their updates quickly. In terms of scan tools, it may be months before they receive or accomplish their updates. Purchasing a scan tool that is not from the vehicle manufacturer may not give you coverage on newer vehicles. A newer vehicle would require subletting to a dealer or other source, a cost the shop cannot control.

With this being said, let’s say 40 percent of your business is GM. Purchasing one of the GM tools might give you a quicker return on your investment in that, with an updated tool, you can control costs. If the majority of your work is not performed on newer vehicles, then a scan tool purchase that has the coverage you need would be a sound investment.

The variable here is, what are my resources for getting this done? If you’re located near a dealership that you can use, this is great. Remember, though, that you still have to schedule an appointment, bring the vehicle, wait for them to be done and pick up the vehicle. So what did this do to your costs? You have people driving vehicles back and forth. You need to wait for them to service the vehicle, and now your cycle time is affected dramatically. A mobile service may save you time but may cost more. This would be a concern on newer vehicles if you do have a scan tool. Could you use a variety of options instead of putting all your efforts into just one process?

Scan Tool Capabilities

If you decide to purchase a scan tool, let’s look at some capabilities. The fact that it may not cover all vehicles is a given. It may not be able to do new vehicles unless it’s a manufacturer scan tool.

The first capability is the person running the tool. Who will it be? You’ll be doing a lot of scans, so ask yourself if you can you afford to have a technician spending all his time doing scans. Technicians are hard to find as is, and to re-task one to scans may be financially taxing to any shop. Training must also be considered here. No tool is completely user-friendly, and some of us are just not computer-savvy.

What if you R&I or repair a bumper cover? Does the tool have the ability to recalibrate? It’s one thing to see codes and clear them, but communicating with the computers to start other processes is completely different. What if you replace the roof and have to recalibrate the camera from the windshield R&I? Does your scan tool or company you’re using have that capability? This is an aiming of sensors, not just checking to see if they work. Do you have the level floor or the lighting needed to use the target? These same recalibrations may be required when doing suspension and alignments that change or affect the vehicle’s ride height, as the sensors are critical to angles functioning correctly.

And now the factor most do not even know to consider: As recalibrations will become more prevalent, how much space do you need? For the recalibration of cameras, you may need up to 27 feet of linear space in a well-lit area void of sunlight and human traffic. The area will need to be somewhat flat and not have objects on the walls that would confuse the sensors. How much space can you afford to give to this? Who gets to do this time-consuming task?

Needs vs. Wants

You want to have it all and be simple. The fact is you can have it all, but simple may not be the term I would use. Getting an aftermarket scan tool and having a plan for vehicles not covered by that tool may be a great idea If you use an outside service, you’ll need to plan for situations that call for recalibrations.

No matter which way you choose to go, communicate beforehand what is needed. Look up all procedures before the repair starts and schedule with resources needed. This will not always be simple and will add a lot to your employees’ list of stuff to do. Staffing for these processes may be an issue too no matter what.

Developing a plan is the best thing to do now and get in practice. Waiting will add a lot of stress to the workplace. If you have a high volume of a particular vehicle line, maybe a combination of in-house scanning and using an outside service will be better for your shop. What you want might change, but it will adjust as you actually learn and see what you need. Just know what you need. In time, better tools will become available as that is the American way. As those tools become available, your wants may change or be the same but better-attainable.

This is just a simple look at what we need to do and what you need to plan for. I want all this to be simple for everyone. That won’t be possible for a while, but I need people to recognize what they need to do and be sure it’s done.