Here’s a high school project that most collision repairers would’ve loved to tackle in their youth: assembling a 1965 Ford Daytona Coupe from 1,000 parts.

That’s exactly what 50 Detroit high school student did, as part of a learning experience created by the Ford Motor Company Fund – Ford’s philanthropic arm – the Detroit Public Schools Community District and the nonprofit group Experience Aviation.

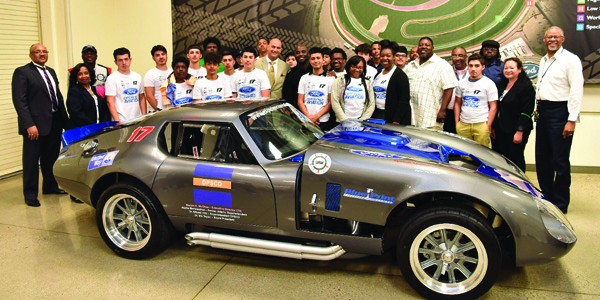

After 18 weeks of assembly, the students gathered in Dearborn, Mich., to unveil their class project.

The hands-on project taught vital skills and provided students an up-close look at how science, technology, engineering, the arts and mathematics come together in a modern work environment, increasing awareness of technology-based career opportunities, Ford said.

“Ford is proud to be a part of a collective effort to help Detroit Public School Community District students prepare for careers in STEAM,” said Shawn Wilson, multicultural manager for Ford Motor Company Fund. “Students who are inspired to learn are better-prepared to reach their full potential in academics and in life.”

Students from the Detroit Public Schools Community District’s Breithaupt Career and Technical Center spent the past 18 weeks assembling the car. It features a Ford 306 engine that delivers 350 horsepower, a Ford TK5 transmission and a new independent rear suspension – all provided with support from Ford Fund. The car was designed by Factory Five Racing.

Instructional support for the students was provided by Experience Aviation by applying principles from Ford’s STEAM Lab digital curriculum. The Ford STEAM Lab was launched in October 2014 to spark student passion for technology entrepreneurship, careers in traditional STEM fields, as well as automotive design and vehicle technology.

STEAM Lab adds an arts component to the original STEM elements of science, technology, engineering and math to help students learn how creativity and innovation can be used in problem solving and collaboration.

Before the test track unveiling at Ford’s Dearborn Development Center, the students were challenged to reimagine how they would improve safety and sustainability through technology. They were joined by students from Douglas Academy for Young Men in Detroit – one of the special STEAM Academies launched by Ford Fund’s Next Generation Learning initiative.

The mini hackathon and panel discussion featured award-winning pilot Capt. Barrington Irving, founder of Experience Aviation, who gained fame in 2007 when he became the youngest person to fly solo around the world.

“The significance of this project is the empowerment and industry knowledge it builds for students,” Irving said. “Now, each student can point the finger at themselves and say, ‘I am the scientist, technologist, engineer, designer and mathematician who made this happen.’”