Is there a difference between a “collision” wheel alignment and a “tire center” wheel alignment?

Is there a difference between a “collision” wheel alignment and a “tire center” wheel alignment?

Depending on what side of the industry you’re in, the answer can be strikingly different. The repair side of the industry is experiencing a disturbing trend, with many crying “fowl” about the capping taking place for wheel alignment.

We’re seeing this happen with a few insurance companies and/or rogue adjustors. It’s been documented that some insurance companies are allowing only the value of what the local tire centers charge for this service — with the insurance representative not taking into consideration the real-world differences between a tire center wheel alignment (or “maintenance alignment”) and a collision repair wheel alignment.

This has become an unfair comparison with the repair side being short-changed on a collision wheel alignment — which, in most cases, is a very technical, time-consuming operation.

It’s well-known that tire centers across the country often use wheel alignment as a come-on or a loss-leader to boost tire and other related sales. Take some of the big-box stores for example, where they’ll often do a wheel alignment at less than cost.

This trend has lead to the type of wheel alignment known as, “Set the Toe and Let It Go” — a term that describes what can only be called a “shallow” or “scratching the surface” wheel alignment at best.

Tire center wheel alignment technicians aren’t saddled with the same in-depth scope of “thought process” or “process of elimination” that a collision technician must go through; there are many more factors inherent to crashed vehicles to consider.

After a collision, it’s expected that the vehicle handled as the manufacturer designed it to. And this places a much higher degree of responsibility on the collision wheel alignment technician, requiring him to look for and to diagnose handling symptoms/characteristics that a tire center wheel alignment technician wouldn’t be expected to.

Tire center wheel alignment will generally focus on tire-wear-related problems (simple camber and toe adjustments) caused by wear and tear, while a collision wheel alignment must go well beyond tire wear and address handling characteristics, which is a much more involved process.

It’s often assumed when collision repairs are completed, if the sheet metal aligns and the vehicle looks good, then the vehicle should be able to have the wheels aligned back to factory tolerances with little or no difficulty. But is that really how it is?

Using the most modern pulling and measuring equipment to complete structural, suspension and steering work (whether on a unibody or a full-frame) doesn’t ensure that the suspension and steering components can be adjusted back into specifications and that the vehicle will handle as is did before. Many conditions will cause a vehicle to be un-alignable, falling into the category of “close, but not close enough.” This common situation can lead to exhaustive diagnostic efforts in isolating the problems and, more often than not, without compensation.

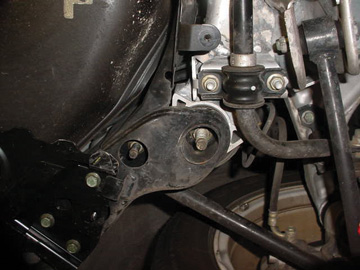

It’s also common that after going through the wheel alignment process, a technician will find that the vehicle will have to be remounted on the frame machine to do some “cleanup work” — additional pulling in the suspension mounting area, an area that can’t be accurately measured with frame measuring equipment.

What follows are conditions that often exist after repairs have been completed:

1. Camber adjustment isn’t sufficient to bring vehicle within specifications.

- Do a SAI check to determine the “included angle.”

- Check ball joints.

- Check strut.

- Check shock tower.

- Check for bent fasteners.

- Check position of engine cradle and/or lower control arm mount area, including engine cradle isolators.

- Check upper control arm mount area.

- Check wheel bearing.

2. Caster adjustment isn’t sufficient to bring vehicle within specifications.

- Check wheel base and lower control arm for damage.

- Check frame length at control arm mount area.

- Check strut tower for rear movement.

- Check ball joint.

- Check radius arm/tension rod, bushings and mounting bracket area.

- Check upper control arm mount area.

3. Right and left caster and camber fall within specifications but the right to left reading isn’t within tolerance.

- Check engine cradle and support isolators.

- Check strut towers.

- Check SAI.

- Check for damaged suspension components.

4. You can’t center steering wheel.

- Check steering sector shaft for twist condition.

- Check right and left steering knuckle/arms.

- Check steering linkage.

- Check steering rack mount area and bushings.

5. Steering has a slight amount of play.

- Check wheel bearing tolerance.

- Check steering gear or steering rack.

- Check inner and outer tie rod ends (remove inner boot on rack-and-pinion-type steering).

- Check idler arm.

- Check steering linkage.

6. Vehicle drifts/pulls.

- Check tires and rotate.

- Check thrust angle (measure wheel base, front and rear).

- Check ride height.

- Check wheel bearings.

- Check brakes.

7. There’s an uneven turning radius.

- Check steering knuckle.

- Check location of steering gear.

- Check steering linkage.

As this list indicates, many conditions can exist after repairs have been completed, and it often takes a thorough inspection of the suspension and steering components along with extensive road testing to diagnose and isolate steering- and suspension-related problems — far beyond what conventional wheel alignment addresses.

Road Testing Tips

For vehicles with suspension and/or steering damage where the obvious damaged components have been replaced, a technician will often have to complete an initial wheel alignment just so the vehicle can be road tested to determine if there are any other steering- or handling-related symptoms.

Symptoms looked for while road testing include (but aren’t limited to):

- Vehicle pulls (air pressure, radial pull or others).

- Vehicle drifts at higher speeds (bad shocks or insufficient caster).

- Vibration at higher speeds (tire balance or drive axle run-out).

- Steering wheel off center (thrust angle or bad steering gear).

- Steering doesn’t return to center after making a turn (bent steering knuckle or insufficient caster).

- Tight spot in steering (bad steering gear).

- Jerky steering (insufficient power steering pump pressure).

- Clicking noise when turning (bad CV joint).

- Road noise (bad tire or inherent to vehicle design).

- Rattles (loose stabilizer bar bushing or shock bushings).

It’s a seemingly endless list of conditions that must be considered when doing collision wheel alignment and the required diagnostic work. And seeing it all down on paper more clearly illustrates the difference between a tire center wheel alignment and a collision wheel alignment.

The data providers go to great lengths to produce fundamental wheel alignment information that’s listed in the Procedure Pages within the Crash Guides. They should be commended for accurately describing what steps are included and what steps are not.

It makes you wonder, when, if ever, have these insurance companies who are capping wheel alignment read the Procedure Pages? Or worst yet, when was the last time you read (re-read) the Procedure Pages? The P-pages are a living guide that’s constantly updated.

The P-page “Included Operations” for front wheel alignment are:

- Position wheels on alignment rack and check/adjust tire pressure.

- Check ride height and adjust to vehicle manufacturer specifications.

- Set-up gauges on all four wheels and check wheel run-out and front suspension for wear.

- Determine vehicle tracking by checking thrust angle to vehicle center line.

- Center steering wheel.

- Adjust front caster, camber and toe-in where applicable.

- Perform vehicle-manufacturer-recommended shimming procedures if necessary.

- Remove vehicle from alignment equipment.

- Verify alignment by road test.

The P-page “Not Included Operations” are:

- Perform diagnostic road test to determine if alignment operations are necessary.

- Straighten or replace suspension parts and/or structural components.

- Shift or align engine subframe/

- crossmember and/or axle housing.

- R&I steering wheel.

- Address non-vehicle-manufacturer shimming.

- Adjust wheel bearings.

- Adjust rear wheel alignment.

Comparing a tire center wheel alignment to a collision center wheel alignment is like comparing the mounting and balancing process for a standard, 14-inch tire on a steel rim to an 18-inch low profile, hard sidewall tire on a $500 aluminum rim. There should be no comparison — the differences speak for themselves.

So the next time you’re offered a wheel alignment at tire center prices, get out the P-pages and educate the person you’re working with. Knowledge and confidence will go a long way in defending what you do.

Writer March Taylor owns Auto Body Hawaii in Kailua-Kona, Hawaii. Not your typical shop owner, Taylor works alongside his employees as a technician. This, he says, gives him “the opportunity to see things how they really are. I’m not disconnected from production or management.”