Early film versions of the Titanic saga depicted

the mayhem that resulted from the mistakes made during the vessel’s

maiden voyage. For its time, Titanic was well-designed. And though

the latest romantic depiction of the ship’s fate might lead you

to believe otherwise, many experts contend that the damage could

have been managed had the true extent of the problem been realized

immediately.

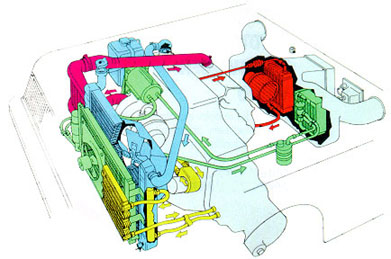

Too often, today’s collision repair shops

work off a similar assumption – that a bird’s-eye view of mechanical

and other related systems is all that’s required to solve the

problem and get the vehicle out the door. One area that frequently

suffers from this assumption is the automotive cooling system.

Cooling-System Concerns

The single biggest concern techs have when

repairing a head-on or front-impact collision is re-establishing

control points and establishing correct datum lines. Often, a

core support is repaired when it should be replaced because it

will be well-hidden behind grillwork, the condenser and other

assorted hardware. The problem with this is that the radiator,

as well as other sensitive components, may be placed under tension

and eventually develop leakage. (Radiator core and other post-collision-related

leaks can be the No. 1 killer of multi-valve aluminum-construction

engines.)

The Automotive Service Association (ASA) says

that even small leaks can result in continually low systems that

transfer steam to critical areas, creating super hot spots as

well as gasket and casting failure. Ever noticed all of the air

bleeds currently found on modern cooling systems? This should

tell you that air – even a little air – is taboo in these systems.

Pressure testing for leaks should take place

prior to draining a system for repairs and after radiator or other

system replacement. If possible, a flush/recycle machine can be

used to remove deposits in the system; it can also do a better

job bleeding the cooling system than if you simply used the factory

bleed screws. Even if you’re not inclined to get involved in cooling-system

recycling services, these reverse-flush machines with pumps are

great for ordinary service.

Cooling-System Check Points

How can you be sure your technicians are conducting

a thorough examination of a vehicle’s cooling system? The following

component check points should prove helpful:

- Radiators – Three- and four-row radiators used to be

few and far between in basic passenger cars, but not anymore.

Hotter-running engines with bigger transmission packages – as

well as other complications created by higher-pressure, hotter

condensers used with H.F.C. 134 – have changed all of that. Today’s

new air conditioners depend on the efficiency level of the radiator

to aid in the convection process when heat is given up at the

condenser. Any radiator problems will make an air conditioner’s

life a very short one if not taken care of directly. Shops should

also check for restrictions from post-collision debris or foreign

material, such as masking paper and the like, that might cause

problems after the repaired vehicle has been released. - Thermostats – It never hurts to replace the thermostat

with the factory-recommended design when you’ve opened the system

for major cooling-system repairs. The reason might be time or

mileage. Also, don’t forget that hard calcium-like deposits knocked

loose during the collision could have made their way into the

water jacket and thermostat housing, causing the unit to stick

shut or open. Take note of how the thermostat is mounted. Some

Ford designs, for example, require that the thermostat be sort

of cork screwed in place. A mistake here can cause plenty of future

cooling-system problems. - Plastic tanks – Plastic tanks on radiators and other

more creative core designs of similar nature can be less of a

problem if you remove the items and do a submerged core test using

air pressure. A leap of faith here – rather than a sure test –

might make you very sorry later. I know of one shop owner who

suggests the customer pay the difference between the component

the insurance company pays to replace and a heavy-duty upgrade,

such as those found in the aftermarket. The difference in cooling

capacity alone makes it beneficial, he says. Add to this the future

reparability of the heavier unit, and it’s a win/win situation

for all involved. - Fans – Electric cooling fans are more survivable than

initially thought to be. The motors will usually hold up even

if they were engaged at the time the impact took place. Being

careful when replacing fan-blade assemblies and mounts can eliminate

vibration and noise, as well as add to cooling-system efficiency

levels.

Cooling fans that are computer controlled through relay banks

or operated directly via sensors are generally very survivable,

say most collision shop owners. Scan tools are a big help in finding

problem areas. Often, a computer sensor or the vehicle control

module (VCM) is found to be the problem when a fan system doesn’t

work properly.

- Belts – Timing belts are good as gold in most vehicles

until around 70,000 miles. Cooling systems that fail after a collision

repair because a timing belt was replaced but a worn or damaged

water pump was neglected seem to be frequent problems for shops.

Insurance companies may not want the extra expense, but who’ll

be left bobbing around in open water when the pump fails a week

later when your customer is driving on the freeway? Keeping the

customer involved in the repair is your best bet here. Be sure

to suggest any repairs that will keep you out of trouble.

And don’t forget to follow routing directions for reinstalling

accessory drive belts and pulleys. We’ve all seen water pumps

and mechanical fans turning backward. These kinds of mistakes

are easily prevented by strictly adhering to parts-manuals data

or by heeding any applicable footnotes.

- Airflow – Today’s automobile is designed for a low

drag coefficient in a wind tunnel, so fairings, air dams and duct

work all must be in place and in proper working order to deflect

cool air toward the radiator and engine compartment to exchange

heat. However, this doesn’t mean we can ignore the need to route

air efficiently and cool the power plant. During inspection for

body or chassis damage, pay close attention to these items so

they can be repaired or replaced correctly to allow for correct

cooling-system operation.

The Right Tools

Failing to locate a clogged radiator, a bad water pump or a restricted

cooling passage won’t make you any more popular than White Star

Lines was just after the sinking of the Titanic. Finding the problems

mentioned earlier will help build a solid reputation for your

shop and put some bucks in your bank account. And with the right

tools, identifying cooling-system problems should be easy.

Toys of all kinds are out there to help you find cooling-system

problems invisible to the naked eye. I came across a neat flow

device that can determine the total rate of flow in the cooling

system. Other neat gadgets that have improved with time are ultraviolet

(UV) leak-detector systems that use dye in the cooling system

to pinpoint small leaks that otherwise might be overlooked.

Prices on this equipment have come down considerably, and any

collision shop could use one for basic inspection, as well as

for the final check before the last road test.

Smooth Sailing

Conducting a thorough inspection of a vehicle’s cooling system

and related parts is an important part of the total repair process.

However, it often gets neglected because many of the necessary

repairs are hidden from the naked eye. “Out of sight, out

of mind,” they often say. Unfortunately, the vehicle won’t

be out of sight for long when the customer brings the vehicle

back to your shop complaining of cooling-system problems you could

have – and should have – fixed when the car was in for repairs

the first time.

Contributing editor Bob Leone, a retired shop owner, is ASE

Three-Way Master Certified and is completing qualifications as

a post-secondary automotive instructor in the vocational school

system in Missouri.

Vehicle maintenance schedules recommend cooling-system services The rules here are simple: If the system has been filled with another type of coolant, namely If you’re working on a system filled with the new organic coolant, Other tips to remember when working with antifreeze include:

|