Not even a blizzard could keep us from fixing the plastic bumper cover of my son’s 2005 Pontiac Grand Am GT Coupe. That’s right. Tammy Horvat, manager of Fred Martin Collision Center in Norton, Ohio, and Dave Cottrell, production manager, generously allowed us to use their equipment and shop last Saturday to repair a crack in the bumper, but Dave texted me the day before to ask if we were still on because the area was expecting four to eight inches of snow and we had to drive an hour south to the shop.

“Well, knowing my son’s enthusiasm for the project and impatience, I say yes, we’re still on…unless disaster strikes and the blizzard hits just before we hit the road,” I texted back.

We did get walloped with the white stuff overnight, but fortunately the plows cleared the roads by the time we took off at 2:30 p.m.

Dave put the vehicle on a lift and took the bumper cover off. I never realized how many bolts and fasteners were involved in what I had previously thought was a fairly simple operation. In the process of doing this, we discovered one of the foglight’s brackets was cracked and one of the headlamps was loose. Easy fixes, just glued the bracket back together and secured a clamp for the headlamp.

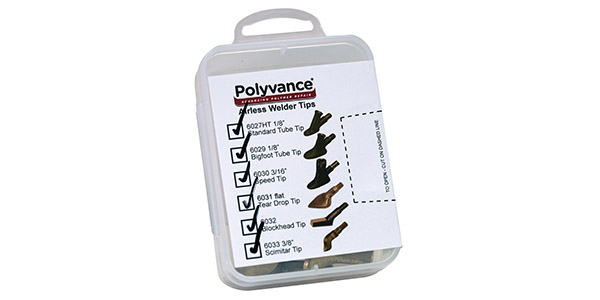

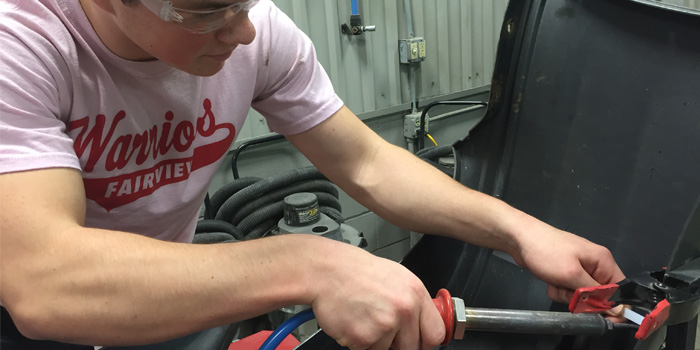

Fixing the crack in the bumper was the really fun part. We used a nitrogen plastic welder, and watching a video beforehand on AutoCareVideo.com helped immensely. On the underside of the plastic bumper cover, we carved fissures into the cracks with a Dremel tool, melted plastic rods into the fissures and then smoothed out the plastic. Then, we used a two-part adhesive and reinforcing screens. Man, did that adhesive stink! I thought a skunk had secretly slunk into the shop. And it was really hard to squeeze the adhesive out of the gun, even for Mr. Football himself!

My son and I traded turns doing the procedure, and as I watched him work away, I marveled at how well he was doing for his first time. More and more, I could see him doing this kind of stuff for a living. Afterward, he said he really enjoyed it and looked forward to painting over our work next…which meant going to get the paint that night, of course! We visited Advance Auto Parts, but unhappy with the color options he saw, we walked away empty-handed. He wanted a PERFECT match and would settle for no less! More work on the car lies ahead, I’m sure, which means more learning experiences.