Your shop replaces the left front door shell on a 2007 Dodge Caliber. Everything looks great and the fit and finish is to manufacturer’s standards. Several weeks later, your customer comes back because the window makes a groaning sound whenever it’s raised or lowered. You confirm the problem and provide your customer with alternative transportation.

Your shop replaces the left front door shell on a 2007 Dodge Caliber. Everything looks great and the fit and finish is to manufacturer’s standards. Several weeks later, your customer comes back because the window makes a groaning sound whenever it’s raised or lowered. You confirm the problem and provide your customer with alternative transportation.

Upon further examination, you determine that the source of the sound is the window regulator, which was not damaged in the accident and thus not replaced. What do you do? Replace the regulator without charge? Explain to your customer that the problem is not accident-related and charge him or her for the repair? Attempt to charge the insurance company (if applicable) for the repair?

This situation could result in unnecessary phone calls, rental car costs, customer satisfaction issues and, above all, time and money. Could this situation have been prevented prior to customer delivery? Yes! This problem is described in a Technical Service Bulletin (TSB) published by the factory.

Here is the procedure for repairing a squeak or groaning noise in the door when raising or lowering the window glass on a 2007-2008 Dodge Caliber. Other vehicles that apply are listed under models.

Application

This bulletin involves lubricating the window regulator rails. Models include:

• 2006-2007 (CS) Chrysler Pacifica

• 2007-2008 (LX) Chrysler 300, Dodge Magnum, Dodge Charger

• 2007-2008 (MK) Jeep Compass, Jeep Patriot

• 2007-2008 (PM) Dodge Caliber

NOTE: This bulletin applies to all 2006-2007 CS and 2007-2008 LX vehicles built before Nov. 14, 2007 (MDH 1114XX) and PM/MK vehicles built before May 13, 2008 (MDH 0513XX).

Symptom/Condition

Squeak or squealing sound from the window regulator area when raising or lowering the front or rear door glass. Groaning sound when cycling the front or the rear door glass to the full up position.

Diagnosis

If the customer describes the symptom/condition, verify that the sound is from the regulator and is not being caused by glass run seals or belt seals. If the condition is present, perform the repair procedure on the door.

Parts Required

Chrysler Part #68003883AA – white lithium grease – 3 oz. tube (one tube will lubricate approximately three doors).

Service Information

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials, removal and installation procedures. Always refer to the manufacturer for questions relating to applicable or non-applicable warranty repair information.

Procedure

1. Remove door trim bolster.

2. Remove the door speaker cover and speaker.

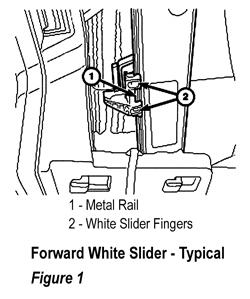

3. Lower regulator to a position where forward (white) slider is visible through opening.

4. Apply 0.5 oz. of white lithium grease to metal rail between slider fingers (Figure 1).

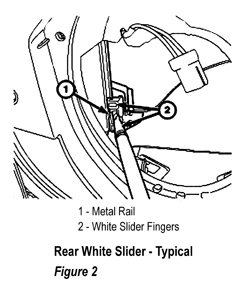

5. Move regulator to position where rear (white) slider is visible through opening.

6. Apply 0.5 oz. of white lithium grease to metal rail between slider fingers (Figure 2).

7. Raise and lower the window three or four times to distribute the grease and verify that the issue is resolved.

8. Install the door speaker and cover.

9. Install the door trim bolster.

10. Repeat the lubrication process only on doors that have a regulator squeak or groan sound issue.

Dan Espersen is the ALLDATA Collision Program Manager. He’s a Gold Pin Member of the Collision Industry Conference (CIC) and holds an AA Degree in Automotive Technology. He has 17 years of experience in the collision industry and 17 years of experience in the automotive industry. © 2008 ALLDATA LLC. All rights reserved. All technical information, images and specifications are from the ALLDATA Product. ALLDATA is a registered trademark of ALLDATA LLC. All other marks are the property of their respective holders. Dodge, Caliber, Chrysler, Pacifica, Chrysler 300, Magnum, Charger, Compass and Patriot are registered trademark names and model designations of Chrysler LLC. All trademark names and model designations are being used solely for reference and application purposes.