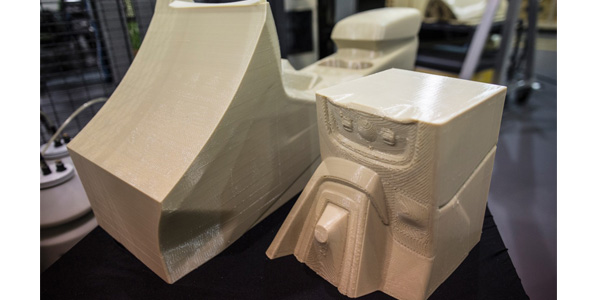

Ford is pilot-testing a Stratasys Infinite Build 3-D printer to see if it’s feasible to print large-scale one-piece car parts – such as spoilers – for prototyping and future production vehicles.

Capable of printing automotive parts of practically any shape or length, the Stratasys Infinite Build system could be a breakthrough for vehicle manufacturing – providing a more efficient, affordable way to create tooling, prototype parts and components for low-volume vehicles such as Ford Performance products, as well as personalized car parts, according to the automaker.

The new 3-D printer system is housed at the Ford Research and Innovation Center in Dearborn, Mich.

“With Infinite Build technology, we can print large tools, fixtures and components, making us more nimble in design iterations,” said Ellen Lee, Ford technical leader, additive manufacturing research. “We’re excited to have early access to Stratasys’s new technology to help steer development of large-scale printing for automotive applications and requirements.”

3-D printing could bring immense benefits for automotive production, including the ability to produce lighter-weight parts that could lead to greater fuel efficiency. A 3D-printed spoiler, for instance, could weigh less than half its cast-metal counterpart, according to Ford.

The technology is more cost-efficient for production of low-volume parts for prototypes and specialized racecar components. Additionally, Ford said it could use 3-D printing to make larger tooling and fixtures, along with personalized components.

How It Works

With 3-D printing, specifications for a part are transferred from the computer-aided design program to the printer’s computer, which analyzes the design. The device then goes to work, printing one layer of material at a time, then gradually stacking layers into a finished 3-D object.

When the system detects the raw material, or supply material canister is empty, a robotic arm automatically replaces it with a full canister. This allows the printer to operate unattended for hours – days, even.

Using traditional methods to develop, say, a new intake manifold, an engineer would create a computer model of the part, then have to wait months for prototype tooling to be produced. With 3-D printing technology, Ford can print the intake manifold in a couple of days, at a significant cost reduction.

3-D printing is not yet fast enough for high-volume manufacturing, but it is more cost-efficient for low-volume production. Additionally, minus the constraints of mass-production processes, 3D-printed parts can be designed to function more efficiently, Ford noted.