For decades, technicians in North America have used frame racks to repair vehicle structural damage. But as the automotive manufacturing industry has evolved, bench systems have been growing in popularity. So is one better than the other? How do you choose between a frame rack and a bench? Chief, one of the world’s largest collision repair equipment manufacturers, offers five tips for deciding whether to buy a new bench or a new frame rack.

“Frame racks and benches both offer certain advantages to today’s collision repair shops,” said Lee Daugherty, director of collision sales, the Americas, for Chief parent company Vehicle Service Group (VSG). “This is why Chief offers both. But we recognize that choosing between the two is not an easy decision, and we would like to help shop owners make the decision that best suits their business, their customers and their bottom line.”

Here are five tips for choosing between a frame rack and a bench when making this capital investment:

1. Consider which type of vehicles you service most

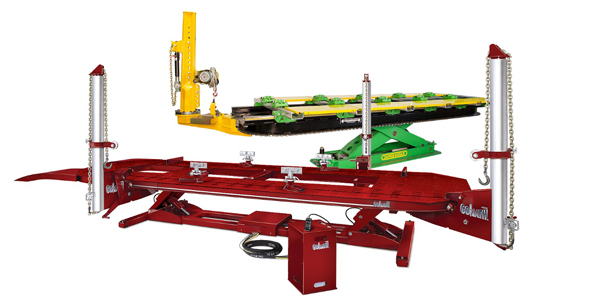

If your shop handles mostly pickup trucks, then you’re probably going to want a frame rack. The best-selling vehicle in the United States for more than 35 years has been a pickup truck, and in huge swaths of the country, shops see more trucks than cars. Large, body-on-frame vehicles like these are easier to fix on frame racks. Frame racks provide a superior platform for providing the pulls and pushes that remain integral to proper truck collision repair.

For shops that service more cars than trucks, a bench may make more sense. Unibody vehicles often require more parts replacement than pulling. A bench is inherently better suited for this type of repair than a rack.

2. Consider your budget

The price tag on a bench system is 50 to 70 percent higher than for a frame rack. There are several types of benches on the market. Some use universal fixtures that give the technician more flexibility in anchoring the vehicle. Others require dedicated fixtures that must be rented or purchased in addition to the bench itself.

If the budget is limited, an economical alternative to purchasing a new bench is to expand the multi-point holding capabilities of an existing frame rack by adding a structural holding system. Structural holding systems are designed to hold vehicles in eight to 12 places instead of just the four pinch welds of a traditional rack. Chief offers adapters that will allow its structural holding system to work with most other rack brands, and has created special adapters that are OEM approved for the aluminum Cadillac CT6 and Ford F-150.

3. Evaluate your available space

The physical amount of space needed around a rack or a bench to perform vehicle repairs, from operating the towers to make pulls or sectioning out damaged parts, is virtually the same.

However, a bench system itself is smaller than a rack, and that offers several advantages. When working with a bench, technicians don’t have to climb or lean over a deck to replace parts, section or weld. Also, some benches recess into the floor when not in use, making it easier to drive a vehicle into position or use a bay for other purposes.

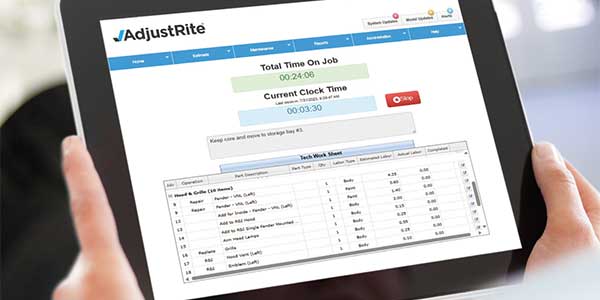

4. Consider training requirements and impact on hiring

Most technicians in North America were trained on a frame rack in school and have used one ever since. It may be easier to hire technicians already trained in the use of frame racks because of their long-time popularity.

Shops that purchase a bench will also need to hire technicians who know how to use it or will need to invest in technician training. Over time, the bench repair methodologies that are migrating from European markets will expand deeper into North American shops, and this will become less of an issue.

5. Follow OEM requirements

Vehicle manufacturers are increasingly specifying the type of equipment that is to be used to repair collision damage to their vehicles. If you want to be approved to repair a certain OEM’s vehicles, you will need to invest in the type of collision repair equipment they require. Check with the OEM’s equipment program for details.

Frame racks and benches are good examples of how collision repair methodology and equipment have continued to evolve and improve. There is no wrong decision when choosing between the two options. Both provide advantages that shop owners should carefully evaluate to decide which will better serve their business in the long run.

“Capital equipment investments for collision repair shops are rarely an easy decision,” said Daugherty. “Shop owners must weigh the benefits for their business, their customers, their employees and their profitability – for years to come.”

To learn more about Chief frame racks or Globaljig Presented by Chief benches, visit www.chiefautomotive.com, contact your local Chief distributor or call (800) 445-9262.