You may have recently read articles or heard about OSHA and a new recordkeeping rule. As with many news releases, you may be wondering, “But what do I really need to know?” In this column, we’ll talk about how this news may affect you and your shop.

You may have recently read articles or heard about OSHA and a new recordkeeping rule. As with many news releases, you may be wondering, “But what do I really need to know?” In this column, we’ll talk about how this news may affect you and your shop.

Injury Data Collection

On May 11, 2016, OSHA issued a final rule to modernize injury data collection. Its goal is to better inform everyone, including workers, employers and the public, about workplace hazards. Did you know that there are more than three million workplace injuries per year, according to the Bureau of Labor Statistics? Right now, a person – whether it be a prospective employee, a business or even the inspectors at OSHA – cannot search for injury data from a specific workplace. Knowledge is power, especially when it comes to safety, and OSHA wants to make this information accessible.

What’s the Rule?

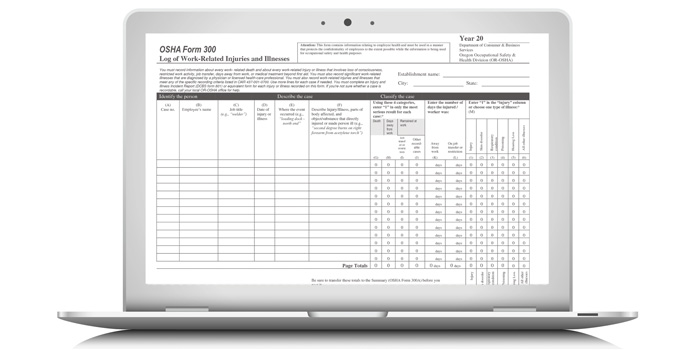

Under the new rule, all establishments with 250 or more employees in industries covered by the recordkeeping regulation must electronically submit their OSHA forms 300 (Log of Work-Related Injuries and Illnesses), 300A (Summary of Work-Related Injuries and Illnesses) and 301 (Injury and Illness Incident Report). Establishments with 20 to 249 employees in certain high-risk industries must electronically submit information from OSHA 300A only.

This won’t require businesses to collect any new information; it will just change the way businesses report their data. OSHA will then post some of the data, which will be available for search and download. To protect confidential information, employee data will not be collected.

The new requirements take effect Aug. 10th, with phased-in data submissions beginning in 2017. Reporting requirements will be phased in over two years. For businesses in states that have an OSHA state program, this rule will also apply, taking effect six months after the final rule. States will have to adopt similar requirements and can choose to use the federal OSHA data collection website or provide their own site.

The Whys Behind It

Although you may not have 250 employees in your business and may not be required to electronically submit the injury data, it’s important to note why this knowledge can be a benefit. Even though your shop may not be required to submit injury information electronically at this time, you can probably assume that at some point this will be a mandate for you as well.

When businesses start electronically submitting injury and illness data, OSHA will be able to use the data to better identify, target and remove safety and health hazards. This will surely result in fewer injuries, illnesses and deaths in the workplace.

As an employer, you’ll be able to use the data to improve workplace safety. Businesses can use this information to measure their own safety performance, comparing it with others in the industry. OSHA says that employers will be able to compare injury rates at their businesses to those at comparable businesses, and then set safety goals based on those benchmarks. As a recruiting tool, employers can use the data to show they’re making injury prevention a priority.

This can be beneficial for technicians and those entering the industry because they can rest assured that safety in the workplace is a priority. Ultimately, the rule will help prevent worker injuries, illnesses and death.

An Important Reminder

Whether or not you’ll be required to report 300 log data electronically, it’s important to remember that all employers under OSHA jurisdiction must report all work-related fatalities within eight hours, and all work-related inpatient hospitalizations, amputations and losses of an eye within 24 hours. This information can be submitted online as well.

Ultimately, it’s up to you to keep your employees safe and make safety a priority in the shop. When you’ve identified the hazards in your shop and trained workers about safety, they’ll watch out for others and themselves. This will result in fewer injuries and illnesses in the workplace, and make reporting a breeze.