Many of you have probably been sending yourself

and your employees to training classes since the early 1980s,

right? Now it’s the late ’90s, and you’re still sending yourself

and your employees to training classes.

Does it seem like it’s never going to end?

To be honest, it probably won’t ever end.

The type of training needed in the future will change, but training

will still be needed to succeed. One of the best analogies I’ve

ever heard about why training will continue to be necessary relates

to milking a cow: The cow doesn’t stay milked! When it comes to

training, there’s always something to learn that will make you

and your employees more competitive.

Before we go any further, take a few minutes

and inventory your training needs by honestly answering the following.

Give yourself two points for every "True" and one point

for every "False."

1. ______ Your yearly closing ratio (number

of jobs vs. number written) for your estimators is below 80 percent.

2. ______ Your technicians don’t accept changes

well.

3. ______ Last year’s net profit was less

than 15 percent.

4. ______ You don’t have regular (at least

monthly) employee meetings or in-house training sessions.

5. ______ Your gross profit on materials

is less than 25 percent.

6. ______ Your training expenses are less

than 1 percent of your gross sales per year.

7. ______ Your staff’s primary training is

from I-CAR; paint, equipment or vehicle manufacturer’s; or no

one.

______ Total Score (Add points scored for

1-7.)

If you scored eight points or less, you’ve

realized the benefit of training and communication for the success

of your business. Great job!

If you scored nine points or more … well

… you’re probably wondering what the heck some of these questions

have to do with training. All I can say is this: If you take the

time to consider the information in this article, I’m sure you’ll

see the relationship by the end (if not, call me).

Training: Yesterday and Today

When I-CAR first emerged on the scene in 1980,

there was literally a crisis at hand. Vehicles were changing,

and the knowledge, skills and equipment were going to change as

well. Those of you who remember the early I-CAR classes remember

the instructor was often just a facilitator of information; many

times, he had just returned from a training session in Detroit

and simply related the "latest" information to class

attendees. Testing or other learning evaluations at the end of

the class were out of the question – no one would have come.

Certainly one thing has changed since those

early classes: The expectations of students have increased. Today,

the normal industry student expects not only to be taught, but

to be kept entertained throughout the class and also for the instructor

to be an expert. This combination has always been difficult to

obtain with a volunteer-type system for any industry – including

ours.

Another change is how outside influences –

insurance companies – have created an overflow of students in

"required" training classes. With so many participants,

enrollment in these classes is often to high to maintain a proper

learning environment. This is a key factor to consider when there’s

no evaluation of learning performed in the classes.

So what’s the answer? As long as any training

course or testing program testing old information is recognized

by an insurer, it needs to be part of your training budget –

if you’re planning on participating in that insurer’s program.

But stopping there will be a major business

mistake on your part. It will be equally important in the very

near future to begin developing your own in-house training programs

and to find higher-level training programs for you and your staff

to remain competitive.

Types of Training

To truly examine training benefits of any

training program, you must first identify the goals and objectives

of the specific training. For this article, I’m going to use the

following classification types for training programs:

- Participation awareness;

- Participation evaluated;

- Independent awareness;

- Independent evaluated.

Each differs in its goals, objectives and in the method it validates

learning, which is ultimately what may be important in the near

future.

Participation Awareness Programs

Participation awareness programs are, by far, the most common

type of training programs available to our industry. As mentioned

earlier, attendees having to validate what they learned would’ve

lessened the attendance count. This still holds true today. Many

of the possible attendees would be opposed to being tested. So,

these classes generally don’t have real hands-on activities. Instead,

they have simulations or controlled projects. No level of competency

is normally required to pass. You just need to be present.

This type of training is where most of the industry and interindustry

courses and seminars are categorized. You attend, and you receive

the "points" and a participation certificate.

What’s good about this type of training? It accomplishes its goal:

Get people involved, and increase general awareness of the subject

matter. That’s simply its purpose, no more or no less.

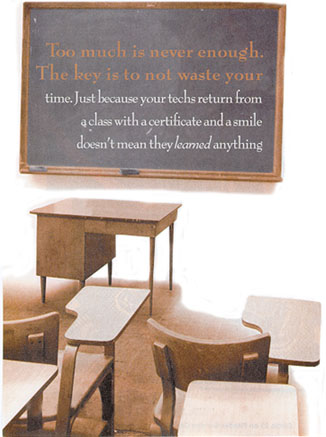

So what’s the downside of this type of training? Even though some

may argue its value and effectiveness based on the instructor’s

quality, there’s still no validation of learning. Without accurate

validation of learning, no class standards are in place to hold

the instructor or provider accountable. No matter how well-written,

the courses are very instructor dependent and can become more

of a "show" rather than a training program. Without

accurately evaluating the student learning, classes that are intended

to last 12 hours can be cut very short, as long as they’re still

interesting. After all, how many people complain that the class

ended early? A few maybe, but not many.

In these types of programs, review questions and home-type exams

are intended to reinforce the learning process and, in some way,

validate learning. Unfortunately, this is very reliant on the

quality of the questions, the method in which the presenter uses

them and how they’re reviewed. In the best-case scenario, they

can assist in clarifying points of content, but they don’t validate

learning or application.

Participation Evaluated Programs

Participation evaluated programs also require the attendees to

be present for the entire seminar, but they include some form

of learning validation as well. This can be achieved many ways,

one of which could be a final exam at the end of the class. Unfortunately,

this can easily result in the presentation "teaching the

test."

Naturally, the seminars that include a final exam that isn’t secured

(secret) have attendees who score very high (look at the other

industry classes that fit into this category. Real estate is one

example). This can be very misleading, since the retention of

the course material may be no longer than the final exam.

You probably can relate this type of training to many of your

secondary-education classes. In these settings, you were often

required to attend the class and pass some type of exam. But,

many times, as soon as the exam was over, so was the need to remember

the information. I bet you can think of a few classes in high

school that fit this example. (Hopefully not all of them!)

Vocational education – properly done – generally goes to the next

level: competency-based performance. This way, the student not

only attends the course and passes written exams, but must perform

to a preset standard. This sounds like ideal education, and it

is, but it’s very costly in time and money – neither of which

is normally available.

The fact that a final exam and attendance are required to get

credit has always increased class participation and focus during

the presentation. But they don’t necessarily translate into validation

of learning. Learning takes time. If the testing was performed

independently at a later date, it would then be able to validate

learning – if the test remains secure. If the test becomes unsecured

and the instructor is given the final exam questions, the instructor

will – whether consciously or subconsciously – emphasize these

points during the course, especially if his performance is based

on how well the students do.

Until recently, this type of training was considered the best

method of "really teaching," when done properly. However,

our industry has had very few examples of this type – short of

top vocational programs – because the secured testing available

doesn’t currently match the latest technology required for today’s

vehicles.

Independent Awareness Programs

Independent awareness programs are available in many forms. A

magazine article such as this one, newspaper articles, TV shows,

reference manuals and computer programs are but a few resources

that can provide this type of training. The key is that there’s

no one checking to see if you’re going through all the materials,

and there’s no testing of information. On the positive side, students

can progress as fast or as slow as they wish with many types of

these programs.

This type of training offers the highest amount of flexibility

and can reach the masses very inexpensively. The TV infomercial

has reached millions and sold many products.

The downside of this type of training? Hitting a learning objective

is difficult, if not impossible, to quantify since no validation

of attendance (completion) or learning is performed.

Independent Evaluated Programs

Independent evaluated programs are best demonstrated in the post-secondary

schools. For many college courses, attending the lectures isn’t

required. Just pass the exams (which, it should be said, isn’t

always easy).

Video tapes with self-testing programs fall into this category

but may not validate learning. They do, however, help teach students

to look up answers. It’s important to note that this process of

knowing where to find information is an important skill. With

the many different "systems" being used today, it would

be very unlikely for someone to know all the systems. But I do

want to clarify that there’s a big difference between knowing

where to find the information and how to use it, compared to looking

up answers to questions and not remembering the answers immediately

after completing the exercise.

Also, Internet and computer-based training (CBT) programs fit

into this category, as long as the final exam is secured. The

students learn at their own pace and then take an exam at the

end.

This category is an ideal learning environment for many students,

but not all. Many students require the interaction with others

to complete their learning cycle. Others can simply read the manual,

watch a video or listen to a tape, and easily pass a written and/or

performance test. This is what makes the need for a secure examination

so important. It becomes the one constant in the learning process.

No matter what form of training is received, the test is consistent.

In the last few years, I-CAR has introduced a performance test

for GMAW welding on thin-gauged coated steel – and more than 50

percent of the journeymen who took the test failed. Recently,

the failure rate has gone down slightly, but it’s still alarmingly

high for such an important skill.

The reason this I-CAR performance test falls into this category

is that the testing process includes a video tape and information

booklet. They both go out weeks before the test and demonstrate

exactly what’s on the test and how to successfully pass it. In

most of the early surveys, no one watched the video or read the

booklet because, since they weld on a daily basis, they didn’t

think they needed to practice or prepare for the test! This attitude

has, most certainly, spelled doom for most.

Using the old way of educational thinking, the test would have

been deemed bad and considered invalid due to the high failure

rate. (See what’s happening in schools today. Scores are bad,

so the test is changed to make it easier).

For any performance testing to be valid, what’s important is that

the test reflects a true representation of an actual job task.

The learning is independent, but the validation of learning is

consistent with industry standards. High failure rates in this

case don’t represent an invalid test but tell us something very

important: We definitely need better training.

What Does Your Business Need?

What would your answer be if I offered to give you $100 for every

$10 you gave me? "What’s the trick?" would probably

be your first thought. But if it were a legitimate offer, would

you decline? (Hint: No way!)

Let’s re-examine your answers to the seven opening statements.

Look at statements 1, 3 and 5 first.

1. Your yearly closing ratio (number of jobs vs. number written)

for your estimators is below 80 percent.

3. Last year’s net profit was less than 15 percent.

5. Your gross profit on materials is less than 25 percent.

All of these could easily be answered "False" after

you’ve learned how. It just takes proper training and support.

What would an 80 percent closing ratio mean to your sales next

year? What would 20+ percent net profit translate into dollars

for your company? How much money does a gross profit of more than

25 percent on materials realize? All of these are available to

you – and the investment pays great returns.

Now look at statements 2, 4 and 6.

2. Your technicians don’t accept changes well.

4. You don’t have regular (at least monthly) employee meetings

or in-house training sessions.

6. Your training expenses are less than 1 percent of your gross

sales per year.

Changes needing implemented can be seen much more clearly from

the leadership position you’re in compared to the perspective

your staff generally has on a daily basis. To get people to change

with the times, they must see the need, benefits and results.

It’s called the vision. Otherwise, it’s like swimming upstream.

How about monthly training meetings? The greatest reasons for

any system failing is the lack of training and communication.

If you don’t consistently send the same message over and over,

learning won’t take place. It takes time.

Along with this, a budget must be established to allow for a consistently

sent message through your organization. In fact, to prepare your

staff for "your way" of doing business, why not establish

your own in-house training programs? For each job responsibility

in your organization, make training modules available to show

employees exactly how you want it done.

And, lastly, let’s consider statement 7.

7. Your staff’s primary training is from I-CAR; paint, equipment

or vehicle manufacturer’s; or no one.

Participation training without evaluation should be considered

when it accomplishes your training goals. However, it doesn’t

validate the competency of those you train. In the future, you

may not be able to rely on others to supply all your training

needs.

Are We Done Yet?

So, how much training is enough? You could probably never get

to that point. As vehicles continue to change, the way we do business

changes, the skill level required to perform the repairs changes

and the level of competition continues to increase.

Those who have in-house training requirements are going to have

a competitive advantage. Some training without evaluation will

always be necessary, but training that accomplishes your objectives

to perform better and be more efficient will require a different

type of training.

The future is closer than you may realize. Many larger organizations

have already put together training centers bigger than your entire

repair facility. Why? Because they realize they need to rely less

on others to provide training – training in which they have little

control over quality, effectiveness or validation. They’ve taken

on more responsibility, but in the process, they’ve also taken

responsibility for their futures.

Can the same be said about you?

Contributing editor Tony Passwater is a long-time industry

educator and consultant who’s been a collision repair facility

owner, vocational educator and I-CAR international instructor;

has taught seminars across the United States, Korea and China;

and is currently an industry consultant. He can be contacted at

(317) 290-0611 or ([email protected]).