A few weeks ago, I was inside the local tire store dropping a car off for an alignment. Standing at the front counter, I was talking with Tom, the store’s manager. As we stood there chatting about our businesses, Tom evaluated a new customer walking into the store.

The customer started brashly asking about the cheapest tires available for his vehicle. As you can imagine, just the thought of “cheap tires” makes the hair on the back of my neck stand up. For several minutes, the car owner kept going on about just putting the cheapest tires on his car because, “All these damn tires are the same.” The car owner went on and on, saying, “Rubber is rubber.”

I thought to myself, “It’s his car and you can’t fix…” Well, let’s not go into what I thought to myself.

Anyway, Tom usually lets his front office staff handle the customers, but this time was different. He politely excused himself and expertly injected himself into the other conversation. Curiously, I went over and looked out the window to see what the customer was driving. He was in a late-model Chevrolet Camaro. Now, even the base model Camaro is capable of producing over 300 hp, and this coupe was not the base model. I immediately understood that the gentleman in his mid-20s was going to end up in a ditch very quickly by putting the “cheap” tires on his car.

Good for our industry, not so good for Tom’s customer.

Good Deal

No doubt about it, everyone wants a good deal, not necessarily a cheap or poorly built product. “Cheap” denotes a lack of quality and longevity of usable life that you won’t get out of a quality product. This is the balancing act we do every day in the collision repair industry. Do you buy a quality product, sometimes at a premium, or purchase products that are less expensive with a shorter shelf life? It’s not such a simple question.

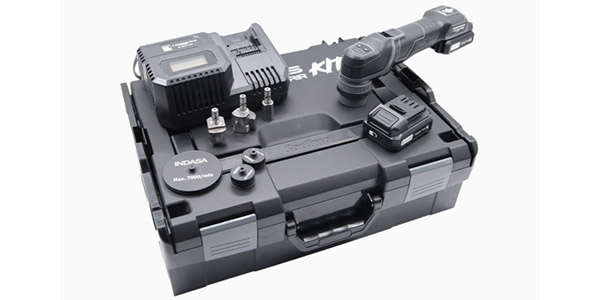

Which leads me to this month’s topic: sanders. Sanders, in many different forms, are required tools in today’s collision repair shop. Body techs and painters rely upon them every day to achieve that perfect finish on your customers’ vehicles. Whether you’re prepping a panel for paint or removing imperfections before delivery, having the quality tool and quality abrasive in your staff’s hands makes the difference between explaining why their vehicle “should look like that” and a satisfied customer.

Like with any other tool, sanders have a lot of different options, configurations, etc. Let’s be honest with each other, when you think of buying shop equipment, your mind immediately goes to the big ticket items: welders, frame machines, spraybooths, etc. Sanders, while a much smaller monetary expenditure, are a huge investment in your shop’s production efficiency and product quality.

Let’s get into the ins and outs of sanders. For the most part, we will discuss random orbital or dual action (DA) sanders. For the purposes of this article, we’ll refer to these uniformly as DAs. We will also touch on hand sanders and abrasives.

Types

DAs come in many physical forms, but only three main power types: air-driven (pneumatic), electric and hand. Pneumatic DAs hold the predominant position in the collision repair industry with the majority of sales each year and have been in use for decades. Electric sanders are a very small percentage of sales today and have a higher initial cost than their pneumatic counterparts. Manufacturers of electric DAs are anticipating increases in adoption in the coming years.

You can’t talk about sander types without talking about the facility requirements to support them. With pneumatic DAs, you must have an adequate, clean and dry air supply within your shop. Humidity and water in your air delivery system will impact the useful life of your pneumatic tools. Many distributors will work with you to determine the quality of your air system and help you determine if you have enough capacity to run your new air tools.

If your compressor is on the borderline of providing enough compressed air volume to adequately supply your facility, an electric sander may be a better choice. Verify you have electrical power close to the stalls in which you’re going to use the tools. Most electric DAs have the ability to finely control the tool’s disc speed, giving you more control over the cut rate.

Hand-powered sanding blocks have been around since man began making smooth surfaces. The flexibility of sanding blocks give them an advantage in situations that require a light touch, inside tight or odd spaces and areas where palm sanders just don’t fit. Sanding blocks also provide the technician or painter the ability to “feel” the surface as they’re cutting the layers down. When it comes to getting the exact angle necessary on a surface, sanding blocks provide you a large amount of options, styles and configurations.

Sizes/Orbits

You’ll find that DAs come in a number of sizes and orbits. The larger the size of the pad and the wider the orbit, the larger the surface area you’ll be able to tackle at any one time. That doesn’t mean you’re going to run right out and buy a bunch of 11-inch DAs with 3/8-inch offset for your entire team. Each sander has a different application, purpose and role within your shop. Make sure you understand the requirements before you invest in a new tool.

So, let’s talk about our size and orbit options. In the collision industry, we generally see the DAs in the 3-inch or 6-inch pad sizes. However, depending on the manufacturer, you’ll see additional pad size options from 3 ?, 5, 8 and 11 inches.

DAs come with different orbit options. An orbit is the curved path of an object around a point in space. The larger the orbit, also called offset, the larger the area being affected in each pass across the panel. Painters gravitate toward 3/32-inch and 3/16-inch orbits, while your body techs typically use 5/16-inch and 3/8-inch orbits.

the ability to “feel” the surface as they’re

cutting the layers down.

Comfort

When you talk with different body techs, each one is going to have their favorite type of DA. This comes from years of usage and figuring out which is the most comfortable to them. I recommend putting the tool in the hands of your techs before you buy. At the very least, make sure to understand the manufacturer’s return policy if you need to return it for any reason. Quality DAs can last decades, so make sure they’re comfortable and get the ones you want.

Weight will also be a factor when determining the tool’s comfort. Advances in composite materials have contributed to weight reductions. Lighter sanders will allow for longer periods of use with less user fatigue.

Vibration should also be considered when picking out a sander. A nicely balanced DA with the appropriate backing pad should be comfortable to use. If the tool feels like it’s coming apart the first time you use it, pack it up and send it back. A tool with heavy vibration will cause user fatigue and possible physical damage to hands and wrists over long periods of time and usage.

Maintenance

The majority of warranty and service requests from quality tool manufacturers come from a lack of consistent lubrication. For pneumatic sanders, maintenance is straightforward: put a drop of oil into the air intake each night. Admittedly, most shops and manufacturers tell you that daily maintenance is often overlooked. I recommend appointing a single individual in your shop to perform this maintenance at the end of the workday. As long as you’re using a drop of oil, any particle contamination in your facility will be kept to a minimum and expelled within the first few seconds of pulling the trigger at the beginning of the day.

For electrical sanders, many are sealed systems requiring limited or no maintenance. As always, consult the owner’s documentation for tool specific maintenance requirements.

Another area that is often overlooked is the replacement of the backup pad. Make sure you replace them every three to six months, as the foam can wear out and deteriorate. Choose the correct stiffness for the work being performed. There are typically two stiffness levels for body work: thin (medium hardness) and thick (super hardness). You also have a painter’s backup pad option as well.

Abrasives

When it comes to abrasives, there a lot of different schools of thought. First and foremost, you need to choose the correct grit size for the job. I spoke to a detailer this week that burned through the paint on a car being delivered that day. He said to me, “They told me to use 3,000, but I could get it done faster using 1,500.” Like I said, use the right grit.

When it comes to the quality of abrasives, I fall on the side of using a good quality product. Think of it like this: you can spend time (technician labor, which is very expensive) swapping out inexpensive abrasives, or you can have them putting the sander to the vehicle for longer periods of time. The quality of the sandpaper will also directly affect the quality of the finish your technician produces on your customers’ vehicles. Supplying your shop with inferior abrasives may cost you more labor and additional rework and negatively impact your CSI.

Warranty

Warranties are only as good as the company that makes the products. When you buy a quality tool, it should come with a minimum of a one-year warranty. There is a price for longer warranties and extended support from the manufacturers, and that’s often added to the initial tool cost. A good example would be purchasing a tool from a local “freight” company and then trying to take it back in 60 days when it blows up. Ain’t gonna happen.

Summary

Leverage your distributors, jobbers and tool manufacturers when you’re considering investing in new tools and sanders. Test out a couple of quality brands before committing to your new DA. You’ll be happy with the results versus going to a local home improvement store every other month to buy another sander. Remember that your time is worth a lot of money, too. By the way, Tom eventually convinced his customer to put on a set of quality tires at a competitive price. Leveraging available rebates, the customer paid a little more than the cost of the cheap tires he was originally demanding. The customer left the store so happy with his purchases that he lit up the tires on the way out of the parking lot. And we know that the happy customer will be back to Tom’s store again…probably sooner than later.

Signs Your Tool Needs Attention

Eventually, you’ll need to have your tool rebuilt or replaced. Signs that your tool needs desperate attention are:

- It makes loud or clunking sounds.

- It needs help starting the backup pad.

- Degraded performance.

- It runs much slower than when it was new.

- It generates excessive heat.

Contributors to this article include David Barleen, CEO, MotorGuard; Glen Bresnahan, national sales manager, Hutchins Manufacturing; David Chao, Prime Supply; Mike Gulley, product manager, Mirka Abrasives; Andy Mandell, marketing manager, Dynabrade, Inc.; and Adam Spah, technical service engineer, Automotive Aftermarket Division, 3M.