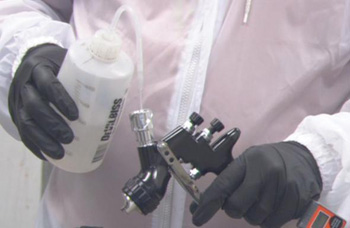

1. A clean spray gun can eliminate potential painting problems. You should only use fresh thinner to clean your spray gun, since using used or dirty thinner can potentially leave a residue behind when it dries. This will not only make cleanup more difficult next time, but the residue particulate can find its way into your next paint job. Over time, the residue can eventually build up, leading to a decline in your gun’s performance.

1. A clean spray gun can eliminate potential painting problems. You should only use fresh thinner to clean your spray gun, since using used or dirty thinner can potentially leave a residue behind when it dries. This will not only make cleanup more difficult next time, but the residue particulate can find its way into your next paint job. Over time, the residue can eventually build up, leading to a decline in your gun’s performance.

2. Always blow dry your spray gun after cleaning. This is especially important for waterborne users.

3. Use proper cleaning brushes, as a spray gun is a precision-made instrument and any damage can have an adverse effect on spray performance.

4. Never soak your spray gun in cleaning solvent for long periods of time, as this can damage the seals.

4. Never soak your spray gun in cleaning solvent for long periods of time, as this can damage the seals.

5. Clean the spray gun immediately after applying waterborne basecoat because waterborne is extremely difficult to clean when it sets too long in the gun nozzle.

6. Regular disassembly and thorough cleaning of the spray gun ensures trouble-free operation and perfect finishes. Breaking down your guns and reassembling them quickly facilitates this and encourages more frequent and necessary cleaning.

7. If you’re going to manually clean your spray gun, check to make sure your state allows this. You should still unscrew your air cap to allow the air to back flush or “percolate” the fluid passages of the gun. There are some products that have incorporated solvent and water to offer a one-step procedure for manual cleaning or flushing of the gun. The air channels of the gun must be protected from these solutions, but these products do speed up the manual process. Remember, these products are for manual cleaning only! Dry the gun after cleaning. Do not soak the gun in the waterborne cleaning solution.

8. With automatic spray gun cleaning, the air passages must be protected and the gun must be dried after the cleaning process. Do not allow the guns to soak in the waterborne cleaning solutions.

8. With automatic spray gun cleaning, the air passages must be protected and the gun must be dried after the cleaning process. Do not allow the guns to soak in the waterborne cleaning solutions.

Information courtesy of Anest Iwata, Collision Center Design, DeVilbiss, Motor Guard and SATA.