Spot Welders

Spot Welders

1. After proper electrical installation, regularly lubricate (with air tool oil) the pneumatic welding clamp, and make sure the compressed air supply is always clean and dry. The pneumatic clamp is the most expensive part of any spot welder, costing anywhere from $3,500 to $5,000 to replace. Removal for factory service is also an expensive proposition.

2. In order to produce a good spot weld, you need a sufficient amount of amps for the right amount of time under the correct pressure. With all that being correct, the spot welder will not produce a good weld if the electrode tips are worn out or contaminated. Replaceable tips are not meant to be redressed, only cleaned; when they’re worn out, just throw them out and install a new matched pair. This is cheap insurance to ensure good spot welder performance and good welds.

3. Keep the diameter of the electrode or welding tip the proper dimension. Not keeping the tip dressed is the biggest mistake spot welding users make!

4. Electrodes are critical in conducting current, applying force to forge the nugget and dissipating heat. Poorly maintained electrodes severely affect the weld quality, diminishing or preventing fusion.

5. One of the most important maintenance items is tips. Since resistance spot welding is applied by electricity (no gas, no added wire), the electrodes are the only things conducting current. Keeping the electrodes sharpened and aligned is critical.

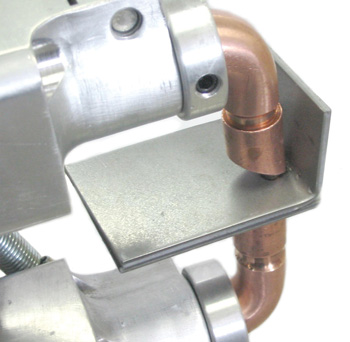

6. To properly maintain a water-cooled spot welder, check the fluid level regularly and follow the manufacturer’s recommendations on when to replace the coolant and filters.

MIG Welders

7. Regularly inspect and clean the steel liner inside the torch welding cable. Metal deposits and dirt build up inside the liner. Also, liners get kinked and dented during normal use. All of this impedes the wire feed, which affects performance and can cause wire “bird nests” between the drive system and the cable connector.

8. Welder troubles usually revolve around expendables and wire. Regularly replace contact tips, nozzles, gun liner and drive rolls. Second, invest in top quality welding wire to avoid lube build-up and copper flaking.

9. MIG welding is about wire feed. Make sure that all parts that make up and affect the wire feed mechanism (spool holder, welding wire, drive roller, MIG gun liner and contact tip) are in good, clean condition. A dirty or contaminated wire feed mechanism will prevent the welder from feeding the wire smoothly, and intermittent arcing will result.

10. Dirt and debris in the environment cause the no. 1 issue: feeding problems due to dirty wire. Therefore, the shop’s no. 1 priority should be, “Keep the wire clean.”

TIG Welders

11. Welding with a worn-out contact tip, clogged liner or contaminated tungsten all create issues for welders – and often, people overlook them as causes. In addition, storing guns, torches or gas hoses is risky business because, if not stored properly, dust, dirt and moisture can collect and cause welding defects the next time they’re used. Gas storage is also a huge issue. If left open, a cylinder can bleed empty in no time. Safe and conservative practices dictate that you should turn off cylinders when not in use, bleed the lines down and back off the regulator handle to remove the pressure from the system. Many people overlook this and waste gas or create unsafe conditions.

12. Another common problem with equipment that doesn’t get used every day is wire corrosion. Sure, copper coatings and lubricants inhibit rush, but not forever.

A good tip is to save the bag or packaging and wrap the wire or filler back in it between uses. If it’s not available, use a garbage bag. For a TIG rod, buy some PVC and a few caps to store the cut length in and keep it away from moisture and the environment.

Information courtesy of AMH, Car-O-Liner, Cebotech, Elektron, ESAB, Lincoln Electric, Miller Electric,

Pro Spot and Tite-Spot.