Manufacturers’ mechanical repair information – including technical service bulletins (TSBs) – benefit a collision shop in three ways:

1. Factory-issued TSBs describe known issues with a vehicle. Suppose you repair a vehicle after a collision and it comes back with a power steering leak. Is it related to your repair? A TSB may reveal that it’s a pre-existing condition. Why not turn it into an income-producing job?

2. Detailed mechanical information can help you reduce outsourcing, increasing your profits and providing more control over the repair schedule.

3. Mechanical repairs offer an opportunity to create a steady stream of customers who may never need collision repairs.

Here’s an excerpt from a TSB issued by General Motors describing the power steering leak:

Condition

Some customers may comment on a fluid leak under the front of the vehicle. Upon further investigation, the technician may find fluid leaking from the power steering system. Use the following information to assist in diagnosis.

Models

2009-2013 GM passenger cars and trucks equipped with hydraulic steering.

Service Information

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials, removal and installation procedures. Always refer to the manufacturer for questions relating to applicable or non-applicable warranty repair information.

Repair Procedure

IMPORTANT: All potential leaks should be completely cleaned and identified before attempting to repair or replace any power steering components.

1. Start diagnosis by inspecting the fluid level in the power steering reservoir. If the fluid level is NOT low, a careful analysis of the condition is necessary as it may involve a different type of fluid leak.

2. Visually inspect the components where the fluid has accumulated.

3. Before the component is replaced, inspect fittings and connections for proper torque.

4. Clean the area around connections, joints and seals with engine degreaser.

5. Add fluorescent dye to the power steering fluid.

6. Start the vehicle and allow the power steering system to reach normal operating temperatures.

7. Turn the steering wheel to the stops in each direction while bumping the steering wheel against the stops three to four times. This will build maximum steering system pressure and help identify the source of the leak if present.

Caution: DO NOT hold the steering wheel against the stops as this will damage the power steering pump.

8. Determine the source of the leak.

9. If a recurring leak is found, refer to the tables below to determine the proper corrective action needed.

Some vehicles are equipped with a “duck-bill” style seal that’s pierced by the power steering line to the gear during installation at vehicle assembly. Vehicles that are equipped with this type of seal include:

- 2010-2013 Buick LaCrosse

- 2011-2013 Buick Regal

- 2007-2013 Cadillac Escalade

- 2005-2013 Chevrolet Malibu

- 2007-2013 Chevrolet Avalanche,

- Silverado, Suburban, Tahoe

- 2007-2013 GM Sierra, Yukon, Yukon XL, Yukon Denali, Yukon Denali XL

- 2006-2010 Pontiac G6

- 2007-2009 Saturn AURA

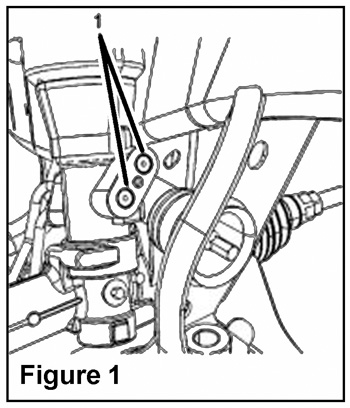

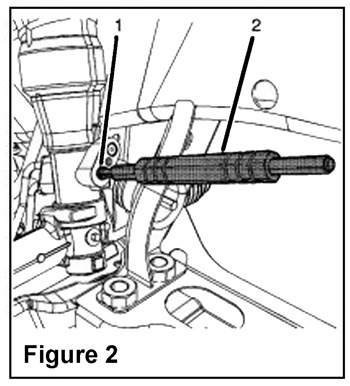

These seals are replaceable, and any leak at the line-to-gear connection on these vehicles should be first addressed with a seal replacement. Use a J-44586 Power Steering Gear Oil Seal Remover/Installer (Figure 2/2) to replace the seals (Figure 1/1-2 and Figure 2/1).

| Source of Leak | Correction |

| Pressure feed and return hoses/lines |

Replace steering line fitting seals, hoses or line set |

| Power steering pump | Reseal or replace pump if necessary |

| Cylinder gear/track lines | Replace O-ring seals or rack lines |

| Source of Leak | Correction |

| Porosity leak in the gear/track housing | Replace steering gear/track |

| Leak from tie rod boots | Replace steering gear/track |

| Pinion seal | Replace steering gear/track |

| Repeatable leak at steering gear adjuster plug | *See note below |

*If fluid is observed at the adjuster plug during the initial visual inspection, refer to the following:

- Seepage at the adjuster plug may not necessarily indicate an active leak. Power steering fluid is used during the manufacturing of the gear/rack. The fluid used at assembly is pushed into the pinion area during assembly. The adjuster plug and the area below the pinion are not positively sealed. Fluid trapped in this area during assembly may seep from the adjuster plug. The rack should not be replaced for this condition.

- You can distinguish seepage from an active leak by removing the left tie rod boot clamp and inspecting for fluid at the inner tie rod.

- If no fluid is found in the left tie rod boot, replace the boot clamp and clean the seepage from the rack. No further action is needed.

- If fluid is found in the left tie rod boot, replace the gear assembly.