After several years of writing pieces on how lean can be applied to collision repair, I still get people asking, “How do I get it done?” Most want to know specifically what they should do, and I often get requests to write articles describing specifically how to change a process. So I’ll say it again: It doesn’t work like that. There’s no one magic answer.

After several years of writing pieces on how lean can be applied to collision repair, I still get people asking, “How do I get it done?” Most want to know specifically what they should do, and I often get requests to write articles describing specifically how to change a process. So I’ll say it again: It doesn’t work like that. There’s no one magic answer.

When it comes down to the “How do I do it?” part, you must realize that it’s about creating the right process to achieve the right result. It’s the “right results” thing that drives the process you must create. We’re all looking for the same result: to make money. But when it comes down to the nuts and bolts of how we work, we all experience different issues. So there’s no right way to do anything. If a process today is delivering the right result for you, then don’t change it. Start by understanding where your results need improvement – then you can start building a better process.

Basics of a Better Process

To understand the specifics of a process change, let’s look at the typical parts procurement process and how lean principles can be applied to it to change the outcome. I’ll start with the result I require: “I need to have the right parts for every job delivered quickly and affordably.” The starting point for the lean process is defining your customer so that you can build the process to serve the person whose money you want. For the sake of this exercise, I’ll say the customer is exclusively the vehicle owner.

The second piece of process building is letting customers’ opinions of what they want to pay for determine what you should and shouldn’t do (because it’s their money you want, so let ’em). You always need a thorough understanding of how anything currently works if you have ambitions of improving it. After all, you can’t fix an engine if you don’t know how an engine works.

Understanding Yield

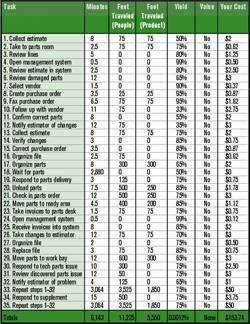

When you set out to improve a process (the parts procurement process), you’re equipped with the understanding of what makes a better business process as well as a basic set of tools that includes things like process elements maps, time observation forms and spaghetti charts – basically, ways to record the details I just listed. A mapping session that observes the existing process details takes place, and the information is summarized as a current state value stream map. This is a complete map of all tasks currently performed and their characteristics laid out like a timeline that helps visually represent reality. For the sake of getting to the point, I’ll lay out an example of what this might look like (see chart on this page).

Look at the results of this current process by starting with the simplicity factor. Today, this operation requires 97 individual tasks to order and receive the correct parts and get them to the technician for installation. This is based on the averages from time studies and assumes that each parts order will need one change from the original estimate (discovered at ordering) and at least one supplemental order either for a missed or wrong part. To perform these 97 tasks, the parts person will travel an average of 11,225 feet – more than two miles. Also, the parts and paperwork travel just over one mile inside the shop, just to get them to the tech for installation. The scary thing is that these numbers are taken from an actual study of one shop’s parts process and is fairly representative of the average.

Next, look at the yield of the process, or the percentage of time that you perform a task and get the desired outcome. You might disagree with some of the percentages in this chart, such as 80 percent for Task 5: “Review estimate in management system.” But think about it for a second. Have you ever looked in your management system for some information and found that it was imported improperly, not imported at all or something was missing from it? If so, then the objective of the task was not achieved on the first try, hence we arrive at 80 percent.

To understand the effectiveness of the entire parts procurement process, you can’t take the average of all the steps because they’re related and thus you can’t perform one without the other. You must multiply each percentage with the next to see what the “rolled yield” of the process would be. In this case, it’s less than 1/100th of one percent. This represents the chance that you could perform the entire operation and achieve the desired outcome. For this process, less than one customer in 100 would have a perfect experience. That’s not a little bad, that’s horrible!

Burn, Cash, Burn!

Now comes the value, which a task is defined as having if the customer is willing to pay for it. It should be used as a road map to understand where you generate cash in your business versus where you just burn money. Based on the parts procurement process we’re examining, there’s not a single task you could bill a customer for that he or she would be willing to pay for. You might disagree (especially if this is your job), but the reality is that the only part of parts that a customer is willing to pay for (exclusive of the part itself) is the tasks related to installing them. I don’t think you could successfully charge a customer a fee to order parts. So this tells you that parts procurement is an area of work that you need to improve because you’re burning a lot of cash here (because it has no sale).

To show how you might be burning cash, I’ve estimated what you might spend in the parts procurement process by using an employee who makes $15 an hour. You would have to add benefits and other things to get a better number, but look at just one parts order – $154 spent just to get the right parts to the tech. Now multiply that by the number of jobs per day, per week and so on. That’s a lot of unneeded and unwanted expense.

So here’s where the initial question, “How do I do lean?” comes back into the discussion. I can’t tell you how you should work. What I can do is help you examine your business and decide what needs work and how to build a better process. Do you really need my help understanding what you need to do to improve the parts procurement process? No. All it would take is an hour or so to make the process simpler to execute and less costly to process with a higher level of quality. For example, stop all the supplements and move all the steps closer to each other. That alone would save a ton.

Dare to be Better

So what specific steps do you need to take to do lean? One, decide that you want better results. Two, decide that Toyota’s business strategy is one you can commit to learning. Three, begin the learning process. Four, start analyzing your own business processes so you know what to go fix. Again, you can’t fix it if you don’t know how it works or that it’s broken. Only after you take all of the above steps can you ask about what you should do specifically to begin the process of lean.

Remember, it’s not about managing to get the correct result. Doing that will only drive you crazy or broke or both. It’s about managing the correct processes that will deliver the results, which is a much easier and more rewarding way to work. Lean is a long-term strategy that takes time to see improvement. But once improvement starts coming, it never stops.

Today, many insurers are learning and applying lean strategies to claims processes. There’s not one that doesn’t have a group of lean managers and departments of continual improvement. Can they successfully implement lean? I guess we’ll see. The good news is that they’ll have to form true partnerships with their vendors (shops) to ultimately deliver the value they create for their customers. And this, in turn, will go a long way to improving your own results…at least those of you who also have lean solutions for your customers and are agile and understand that waste elimination is the perfect fit.

Contributing editor John Sweigart is a principal partner in The Body Shop @ (www.thebodyshop-at.com). Along with his business partner, Brad Sullivan, they own and operate collision repair shops inside new car dealerships, as well as consult to the industry. Sweigart has spent 21 years in the collision repair industry and has done everything from being an independent shop owner to a dealership shop manager to a store, regional and, ultimately, national director of operations for Sterling Collision Centers. Both Sweigart and Sullivan have worked closely with former manufacturing executives from Federal-Mogul, Morton Thiokol and Pratt & Whitney in understanding and implementing the principles of the Toyota Production System. You can e-mail Sweigart at [email protected].