In times like these when body shops are over-leveraged, underpaid and short of vehicles to repair, any sources of income are welcome additions to the bottom line. One such source of income could be hinge repairs on General Motors C and K series trucks and SUVs, known to have problems with wear-and-tear on their upper and lower door hinge bushings, making the doors hard to open and close. In terms of trucks like these involved in collisions where the hinge pillar, doors or their hinges have been damaged, it’s a no-brainer to address this OEM oversight and provide yourself with an additional source of labor and parts sales.

In times like these when body shops are over-leveraged, underpaid and short of vehicles to repair, any sources of income are welcome additions to the bottom line. One such source of income could be hinge repairs on General Motors C and K series trucks and SUVs, known to have problems with wear-and-tear on their upper and lower door hinge bushings, making the doors hard to open and close. In terms of trucks like these involved in collisions where the hinge pillar, doors or their hinges have been damaged, it’s a no-brainer to address this OEM oversight and provide yourself with an additional source of labor and parts sales.

Wear and Tear

Many factors can weigh on – literally – the lifespans of hinge assemblies in modern vehicles. For example, power windows add additional weight in the doors that, in turn, adds to the wear and tear on hinge assemblies. Furthermore, in cases where trucks have had a lift kit installed or when trucks have short owners, passengers and drivers alike tend to use the doors to help them get into the cabs, which is a known cause of wear on the hinges. What this adds up to is demand for hinge rebuild services – another customer-paid tool you can add to your shop’s sales arsenal.

There are several styles of hinge repair kits available that are designed to repair/replace worn hinge bushings on 1999-2007 C and K series pickups and 2002-2007 GM S and T series SUVs. The models covered are the Sierra, Silverado, Suburban, Tahoe, Yukon, Avalanche, Escalade and ’03-’08 H2 Hummers. These late-model truck platform vehicles are known for durable drivetrains, but fall short on some interior build materials quality and braking system durability. Still, there are millions of these truck and truck-based SUVs on the road today, every one of which has an OEM blindspot in their door hinge construction.

Repair Methods

What body shops want to look for is a kit that will allow for future bushing replacement due to normal wear. Because no bushings last a lifetime when you’re talking about trucks with a life expectancy of 200,000-plus miles, you may find yourself replacing the pins and bushings again.

Repair methods include:

A. Complete hinge replacement (labor hours = 8); not serviceable.

B. Replacing knurled pins and bushings (labor hours = 2); no longer serviceable.

C. Replacing bracket with screw-in pins and bushings (labor hours = 1/2); serviceable.

Because there are pin and bushing kits available, repair method A (complete hinge replacement) is no longer necessary.

Most kits for repair method B (replacing knurled pins and bushings) require the pins to be beaten out with a hammer and punch “per their instructions.” This procedure has a tendency to bend either the hinge or the hinge brackets. A bent hinge bracket will defeat the purpose of replacing the pins and bushings as it may cause a slight but nonetheless significant hinge misalignment, which will result in premature bushing wear. These knurled-style pins don’t always seat properly, which will again result in premature bushing wear and will, in some cases, even snap off during installation. This repair method also requires you to repaint the bracket, adding additional materials and labor.

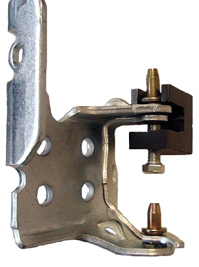

The kit in repair method C (replacing bracket with screw-in pins and bushings) includes a new hinge bracket and stainless steel threaded pins. These pins screw into the bracket for a uniform fit every time, with less than a half hour of labor. This will allow the shop to simply unscrew the pins and replace the bushings when necessary due to normal wear. These kits come with a die-chromate coated bracket, which requires no painting, or in factory colors.

Also offered with this kit is a pin removal tool that presses the pins out without wrecking the hinge bracket welded to the pillar. This is extremely important because wrecking the hinge by pounding out the pins will leave the repair facility with no choice but to perform a complete hinge replacement costing over $1,000.

Demand = Profit

Celena Knebel, owner of Knebel Body and Paint in Buffalo, Wy., a town in the northern half of the state at the foothills of the Big Horn Mountains, says her shop does a fair amount of hinge rebuilding.

“I wouldn’t say a majority of our customers need it, but we do have a lot of trucks here in our area with ranchers,” she said.

She said the kit comes in handy if the truck needs a door shell, and a lower skilled tech can handle the job with some coaching.

Knebel says she charges about $320 for upper and lower hinge rebuilding. In terms of profit margin, she said they make about $200 after accounting for the cost of the parts. Her shop charges about $200 for labor, and adds that she has had insurance companies pay for the service on a hinge repair kit on trucks and SUVs with heavily damaged door assemblies.

Another person who’s uniquely situated in terms of her experience with truck hinges is Bunny Wampole, parts manager at Bob Spady Pontiac-Buick-GMC in North Platte, Neb. To say the demand for hinge replacement in her area is huge would be an understatement the size of, well, Nebraska.

“We have the biggest railroad yard in the world out here,” Wampole said. “It runs 24/7, so the trucks there are subjected to heavy use, with their drivers getting in and out of them all day. I’ve got some customers with over 300,000 miles on their trucks.”

Spady’s parts department sells the kits for repair method C to the body shop as well as to area repairers. She says she pays $54.95 for each of the hinge kits and they list at $96 compared to $400 for the new OEM hinges.

“They’re holding up very well, they’re easy to install and require about a third of the labor to service,” Wampole said.

Sell, Sell, Sell!

Up-selling is the name of the game here, as any intelligent business person will understand the value of additional service and parts sales to vehicles that are captive in his or her system. While frontline body shop office people often don’t consider themselves salespeople, the ability to sell has become a highly valued skill in collision repair. As such, a front office person in an up-sell mode should be on the lookout for repair opportunities outside the collision repair market, such as wheel alignments, detailing and installation of accessories, to name a few. Rebuilding door hinges on these popular truck platforms – particularly for shops in strong truck markets – is a great way to add some additional customer-paid labor to the shop ticket, particularly with those vehicles that are in the shop for other repairs. A

Writer Charlie Barone has been working in and around the body shop business for the past 35 years, having owned and managed several collision repair shops. He’s an ASE Master Certified technician and a licensed damage appraiser, and has been writing technical, management and opinion pieces since 1993. Barone can be reached via e-mail at [email protected].