This article is the first in a series on battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs).

There is no question that battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs) are becoming an important part of the automotive industry’s future, with OEMs committing significant resources to this growing sector. To that end, one of the most common questions I hear within the collision repair industry is, “How and where do I get started?”

It’s easy to get caught up in the whirlwind of conversations happening around these progressive vehicles, including the desire to add a potential new revenue stream to your repair business – especially during these challenging times. But make no mistake, repairing these sophisticated vehicles requires taking into consideration some very important factors.

Consider the following as an initial checklist to jumpstarting your BEV/HEV game. Future articles will dive into specific repair considerations, only reinforcing the importance of ensuring that foundational elements are in place.

A Matter of Life and Death

BEV/HEV safety rule no. 1? Don’t become a conductor.

Don’t fool yourself, your body can and will conduct electricity, and with enough difference of potential (voltage) across your body (or parts thereof), a current can flow through your body and you will experience the unique phenomenon of shock. There are enough stories out there of DIYers taking BEV/HEV repair into their own hands with devastating results. Safety simply cannot be overlooked; electricity will take the path of least resistance. It will find and take all available routes, even if they’re unintended. If you give electricity the opportunity to flow through your body, it will!

While EVs share many similarities and operational principles, they are not all the same.

It’s very important to delegate a space within your shop for BEV/HEV vehicle repair where you can limit access/entry to only those authorized to work in the space. Yellow and black tape and caution/danger signage are all important elements to reinforce the importance of this dedicated environment, while ensuring that each and every full- or part-time staff member understands the seriousness of these life and death boundaries.

PPE Matters

Most people are unaware that the human body sends out small electrical impulses throughout the day to aide in performing a variety of everyday functions. Technicians working on low-voltage systems may touch the positive and negative terminals of a 12-volt battery and not feel a thing. But guess what? Electrons are still flowing through the body.

Some may believe they don’t need special PPE gloves, saying, “I know what I’m doing.” But every step in a HV shutdown and isolation procedure is in place, specifically as written in the service information, for a reason.

Wearing PPE adds another level of protection in the event of an unseen or unknown danger or fault, including accidently touching something that is energized.

Additionally, if an unforeseen incident occurs, PPE insulates technicians from potential shock, an arc welding flash or blast. Keep in mind that electricity does not produce a taste or smell, and you can’t see it unless it’s arcing or sparking.

Don’t risk your life on the presumption that “it’ll be ok, I don’t see anything wrong.”

As technicians, we like to take stuff apart; we want to get in there get the damaged stuff “out of the way” so we can move forward with the repairs. I can’t overemphasize the importance of looking before you leap or, in this case, touch.

While EVs share many similarities and operational principles, they are not all the same. Take time to become familiar with the overall vehicle, from understanding the location of all of the HV system parts to cables and how these elements are routed. Assess if any of these items are damaged. Know your opponent before you head “into the ring!”

Powering It Down

How can you be sure there is no voltage present? Don’t risk your life on the presumption that, “It’ll be OK, I don’t see anything wrong.” Odds are yes, it will probably be OK, but are you willing to take that chance? Ensure that you have proven high-voltage system disablement and high voltage is isolated to the battery, with no residual voltage in the isolated systems.

Tools of the Trade

Scan tools, digital volt ohm meters (DVOMs), dual-pole testers, milliohm meters and megaohm testers are just a sampling of the tools of the trade, with some unique ones specific to certain brands and makes. Being familiar with the vehicle and its systems is one part of the equation; the other part is truly understanding the test equipment, its functionality and reliability.

I-CAR HEV/BEV Courses

Currently Available:

- Hybrid Vehicle Identification and Damage Analysis

- Hybrid, Electric and Alternative Fuel Vehicle Service

- Introduction to Electric Vehicles

- Understanding High Voltage Safety

Available Late Q1 2021:

- Electric Vehicle Inspection and Handling

- Electric Vehicle Damage Analysis

- Electric Vehicle Service Considerations

Take the time to establish confidence with the accuracy of results and notifications. This includes being able to achieve a “zero potential status/notification” in new equipment after performing a disconnection procedure to switch off the HV system. Be advised that a regular shop multimeter should not be used; too many errors can happen, including setting an incorrect measurement group. Using a dual-pole voltmeter, you can only measure voltage, thus eliminating the potential for errors.

Additionally, a milliohm meter should be used to measure the component bonding, as well as an insulation tester to help ensure a safe environment.

Eyes on the EV

The inspection process starts when the customer drives the vehicle in, or the rollback drops it off in the lot outside. There are aspects of BEV/HEV repairs that are different from conventional petroleum-fueled vehicles, thus you should be aware of everything from the HV battery’s state of health to its cooling system and HV systems – in addition to all of the usual mechanical and body inspection points. And I would be remiss if I did not mention the ADAS and other technological features found in today’s vehicles.

Charged Up

Installing a charging station is highly recommended. A wall-mount station with a charging monitor is currently the best solution in that it only requires a charger with an ICCB (in cable control box), which acts to supervise the charging mode.

It’s critically important to always unplug the vehicle from a charger when somebody is working on the vehicle. The system is considered “live” when plugged in and charging, so working on a vehicle in this condition can be dangerous.

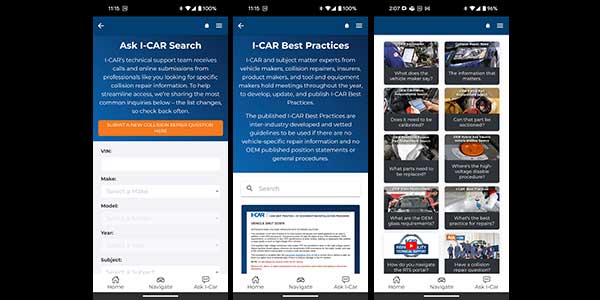

Training

There’s much more to consider when repairing BEV/HEV vehicles than what is outlined in this article. Rather, I’d like to get you thinking about the opportunities ahead in your professional career as vehicles continue to evolve and repairs become more surgical in every way. The choices you make not only impact your safety and livelihood, but also have possible repercussions to the lives of the families that drive and perhaps test your work on the roads of America. Your investment in training is an investment in your future, invest wisely.