How can we showcase our refinishing skills in a manner that separates us from other shops and drives business to our door? I’m not sure we can; yes, we can show before-and-after images on a website, talk about our integrity and quality, use paint manufacturer tools and posters in our waiting areas, or mention our lifetime warranty. But how does any of that distinguish us from the competition and bring us cars to fix?

Just what exactly does drive customers to your shop? Traditionally, for the first visit, it has been DRPs, effective marketing campaigns or word of mouth. What brings them back a second time, however, will be based on that first experience. And with social media, your customer is more likely to “talk” about that first experience in a way that has proven to be yet another driver of business – either to your door or to your competitor’s, depending on whether their review is positive or not.

Social media is not limited to millennials; I was born in the early 1960s and my age-appropriate wife will check Yelp! or Google reviews after seeing, reading or hearing about a product or service she is interested in – every time. The word of mouth she gets from a friend will carry more weight than a stranger’s review, but she will still check the online reviews. While she doesn’t read them all, she’ll read a few of the one-star reviews and weed out the silly ones. For instance, a one-star rating with an explanation of, “…had to wait too long as they were really busy…,” doesn’t paint a fair picture unless that’s a common theme in the reviews – which would suggest a scheduling or staffing issue and not necessarily indicate ability or quality.

So how can we sell our refinish capabilities in a manner that creates customers for us? It’s a little like the chicken-and-egg dilemma – we need the opportunity to prove our refinish capability to earn a positive review that will continue to drive work through the front door.

An Imperfect World

The advertisement we craft to convince the consumer of just how great we are and why they should be coming to us should avoid words like “flawless” or “perfect.” It’s an imperfect world filled with imperfect humans doing imperfect work. Excellence is what we strive for, not perfection. I’m a fan of never-ending improvement, but let’s be honest – “flawless” creates an unrealistic expectation for the customer. Instead, we should talk about our crew’s wealth of experience or how long our shop has been rooted in the community. We can brag about the average tenure of our dedicated employees, but let us avoid claiming we have perfect color match. Color perception can be subjective, and what matches for you may not be perceived as a match for the customer.

Reporting from the Back Door

Customers are 15 times more likely to talk about your shop if they’re dissatisfied with the repair or, more accurately, their experience. Therefore, what happens between the front and back door is critical for building the clientele who faithfully review the shop in a positive light which, as we’ve already mentioned, drives consumers through the front door. Our goal is to give the customer an excellent experience. You may disagree and say the goal is to fix cars correctly in a timely and profitable way, and while I don’t disagree with that, I would ask you to consider the owner of a “totaled” vehicle. The train wreck is towed in and totaled. The customer comes to the shop to retrieve their belongings. You never repaired that vehicle – didn’t even have the opportunity to – but the owner of the vehicle still had an experience at your shop they may Yelp! about.

Before we discuss the paint shop, let us be mindful of the initial contact experience the customer has, either in person or on the phone. Are you and your crew treating people as you would want to be treated? You know, the “golden rule”? The average customer comes in traumatized by their first accident that damaged their second largest investment and is in a totally unfamiliar environment. There is lots of customer service training available, so I encourage you to reach out to your paint manufacturer rep and ask about resources that are available to educate your staff.

Between the Front and Back Door

Let’s assume we have the vehicle in the shop. What can we do, between the front and back door, to make an impression that has enough impact to attain that positive review? If we’re not concerned with a “perfect” color match, then what are we concerned about in the paint shop and how do we capitalize on it?

Invisible repair. Back in the paint shop, we’re aiming for our paint job to be unnoticeable – an illusion of a “perfect” repair. This goal dictates several things, and we’ll explore the process starting from the end-goal and working back.

A clean vehicle. Elementary, I know, but let us remind ourselves: that is the first impression the customer will have of the finished product. Avoid making a bigger mess of the car with disassembled parts in the back seat, or allowing a “doorless” car to make the trip through the shop without protective masking.

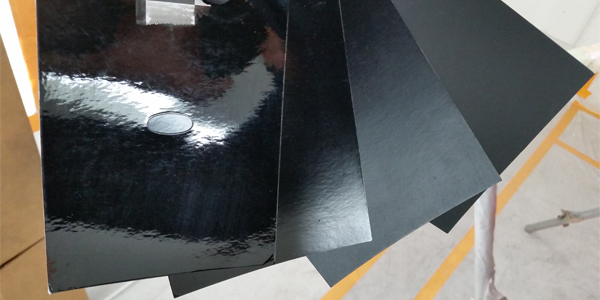

Texture and shine. If the vehicle is a matte finish, then you’ll likely need to zone-refinish the repair – perhaps not, but likely. If the front edge of the door was damaged and repaired, you may want to clear the entire side to achieve a uniform degree of gloss, as opposed to only the damaged and blend panels. Remember, a variance of gloss will render a perception of a different color. With a standard gloss finish, we need to pay attention to the texture we’re attempting to duplicate. Yes, texture. It is very unlikely that any job in the shop is without texture. The vehicle manufacturer leaves plenty of texture in the finish, and if we want our repair to be invisible, then we must not buff it all out nor apply the clear too slick. Adjusting the distance, speed or overlap of the spray gun as well as air pressure or activators will all have an effect on the texture. Spray it the way you want it to look.

Color match. There are too many variables affecting color perception to catalog them here, but suffice it to say that there’s a reason paint manufacturers have a position statement stating the need to blend. They all speak of a “blendable match,” and this is what we aim for. However, the color must be blendable, and not everything will blend out invisibly. An improper effect of metallic will render a dark or light cloud that you cannot make invisible. The need to match color still exists. You still need to make a spray-out of the color and adjust if necessary. Photo document the spray-outs to capture “tint” time on the estimate. And then blend! It’s incredible how often I see time and material wasted in the attempt to achieve a butt-match when the obvious answer from a production and profitability standpoint is to blend.

However, we do need to address butt-matching bumpers, as the industry standard for a bumper refinish is an acceptable degree of mismatch due to the plastic/metal challenge as well as differing angles from the sheet metal to the bumper cover. “Acceptable degree of mismatch” – if that’s not subjective, then I don’t know what is. We’ll talk more about this later.

For the final product to appear invisible, the foundation must be sound. The body work and seam sealing needs to fairly duplicate what the vehicle manufacturer did. The same goes for welding. On a core support where welds are visible, they need to mirror factory work (unless the repair procedures instruct otherwise) or else the repair will never be invisible as the clues of the repair will telegraph through the paint work.

Manufacturers and suppliers of seam sealer have resources available either as in-shop demos or website videos to achieve a factory look. YouTube will also have some nuggets of information, but a word of warning: don’t wander too far from manufacturer videos. And naturally, some practice to achieve the OEM look may be required.

Communication

When it is not possible to perform an invisible repair, such as on a vehicle that has had a previous low-quality paint job, you need to have a conversation with the customer. Your excellent repair and finish will stand out from the previous faded finish. This is where you manage your customer’s expectations with communication. The same goes for butt-matching bumpers; you must communicate how metal/plastic substrates will affect the color at the beginning of the process, not during delivery of the vehicle. Explaining how metallic behaves differently on plastic as opposed to metal only sounds legit at the beginning of the process. Trying to calm a customer’s concerns at the time of delivery sounds like a clumsy attempt to excuse an “acceptable degree of mismatch.” A “diamond” card is a great tool for illustrating the effect of different angles on perceived color and is more effective at the beginning of the process.

We also must keep the customer updated regularly by proactively calling them. Don’t wait for them to call you. Think about how their review will read: “I had to call the shop for updates,” as opposed to, “They kept me abreast of my vehicle’s progress.”

Summary

Every shop that is in business can fix and paint cars. What are we doing that separates us? Back to that golden rule: we want their experience to be as positive as possible because ultimately, it is the customer who is selling our abilities and setting us apart.