Editor’s Note: Schoonover Bodyworks & Glass sold its Stillwater location to ABRA Auto Body & Glass on Nov. 19, 2012, after this story went to press.

Location: Shoreview and Stillwater, Minn.

Established: 1938

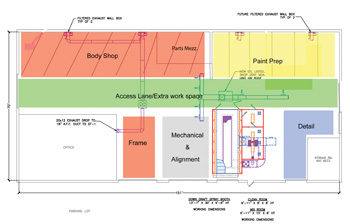

Square Footage: 14,000 square feet

Owner: Mike Schoonover

No. of Employees: (14) – 2 administrative, 2 sales, 1 parts & production manager, 3 bodymen, 1 glass worker, 1 mechanic, 2 painters, 2 detailers

Gross Sales: $5,000,000

Repair Volume/No. of Cars Per Month: 200-plus

Average Repair Cost: $2,900

DRPs: 12 (State Farm, Allstate, Progressive, Farmers, Liberty Mutual, MetLife, etc.)

Behind the Bays

Estimating System: CCC ONE

Management System: CCC ONE

Spraybooth: Sterling waterborne booth

Lifts: Nussbaum

Measuring/Dimensioning System: Chief/Car-O-Liner

Welding Equipment: Pro Spot i4 spot welder

Paint Mixing System: Sikkens AutoWave

Paint: Sikkens AutoWave

Future Equipment Purchases: None

“Learn from the past” is a key mantra for Mike Schoonover. As a third-generation shop owner of a family-run business, the collision industry runs vigorously through his veins. While he has applied the knowledge he has gained from his predecessors to his business practices, he also strives to make Schoonover Bodyworks & Glass his own.

With two locations in Shoreview and Stillwater, Minn., the stores offer Twin Cities customers not only collision repair but other auto-related services.

“You have to give [customers] the extra effort to make them go ‘wow’ and want to return, or refer family and friends,” Schoonover says.

And by paying attention to his customers, as well as the business’ previous owners, Schoonover does just that.

Past to Present

It was a different world back in 1938 when Schoonover’s grandfather opened the business. Perhaps the biggest change in the industry has been related to insurance, which Schoonover recently discovered after uncovering a few old photographs. The photos, taken from multiple angles, were of some damaged vehicles that had suffered fresh collisions.

“It looked like [my grandfather] was taking pictures for the insurance company,” he says. “It’s just kind of funny. Back in his day, insurers didn’t have claims offices. Shops dealt directly with each insurance agent, and the insurance agent would pay the bill. Obviously, there were no DRPs or anything like that at that point.”

“It looked like [my grandfather] was taking pictures for the insurance company,” he says. “It’s just kind of funny. Back in his day, insurers didn’t have claims offices. Shops dealt directly with each insurance agent, and the insurance agent would pay the bill. Obviously, there were no DRPs or anything like that at that point.”

Schoonover got a taste of the industry at a young age. His father, Dick, frequently brought him along to NACE and other industry functions. And while technology and other aspects of collision repair have evolved over time, core issues have not.

“I was in a room as a little kid listening to the same things that we’re talking about today…these things about insurance companies and what they were doing at the time and what they were requiring shops to do,” he said.

After his father retired in 2000, it took 10 years for Schoonover to gain full ownership. Following in his father’s footsteps, he decided to get active in the industry by joining organizations that advocate for repair shops and their owners: the Automotive Service Association, I-CAR, the Alliance of Automotive Service Providers of Minnesota, as well as the CAPA technical committee.

“I think volunteering my time and getting active in these different associations and groups has been very beneficial,” said Schoonover. “I’m ‘in the know’ of what’s going on, and I get to meet the Randy Hansens and George Averys and the guys that are out in the industry.”

His Own Way

Although he has learned some valuable things from his father, Schoonover has his own method of running his business. While his father was a well-respected industry member, he was also a hard-nosed businessman.

“You knew where you stood with him,” Schoonover recalls. “He was very quality-minded, detail-oriented and customer service-minded, and he expected everybody to give their best. If there was an issue or disagreement with an insurance adjuster or executive, he would let them know his displeasure.”

Schoonover, on the other hand, takes a more understanding approach when dealing with these situations. “I’ll sit down and chat with someone about a problem. I don’t want to say [my dad and I] are polar opposites, but we have our own way of doing things.”

Schoonover also attributes the differences in his management style and that of his dad’s to the industry itself.

“I think back in those days, it was probably more rough and tumble. [My dad] was in an era where there were a lot of changes to your vehicles and your equipment and how you ran your shop and how your customers were expecting to be treated. And we’re just kind of used to those changes now. We live in a society where cars and phones and computers are disposable. There may not be the same type of commitment between employer and employee or customer-type relationships, so it’s just a different world. I think you’ve got to be more prepared for change and adapt to it these days and going forth.”

“I think back in those days, it was probably more rough and tumble. [My dad] was in an era where there were a lot of changes to your vehicles and your equipment and how you ran your shop and how your customers were expecting to be treated. And we’re just kind of used to those changes now. We live in a society where cars and phones and computers are disposable. There may not be the same type of commitment between employer and employee or customer-type relationships, so it’s just a different world. I think you’ve got to be more prepared for change and adapt to it these days and going forth.”

Going with the Flow

Adapting to change is core to Schoonover’s practices, and he’s often quick to do it. After noticing that print media was diminishing, he decided to step up his marketing by renovating his business’s website. It took a couple of years to put together, but it was worth the effort. The once dated-looking site now sports a clean, user-friendly and eye-catching design. A lively animation of a car crashing grabs visitors’ attention as soon as they enter the home page. The phrase “We can fix that” then flashes across the screen as the car is magically fixed, reassuring visitors that they’ve made the right choice. From there, customers can check their vehicles’ repair status, learn about repair processes and view shop specials.

Schoonover also decided to go green long before most shops by switching to waterborne paint. His shop has been solvent-free for about five years, and he has never looked back.

“It’s better for the environment, and we have good, color-matching finishes,” he said.

Similar to adapting to evolving technology and industry standards, Schoonover also sees adjusting to insurers’ role in the industry as a vital component to survival. One way he does this is by sponsoring continuing education classes for insurance agents. These AkzoNobel/ Sikkens-conducted classes allow the business to build a stronger relationship with its agents. The courses, held twice a year at two different locations, focus on ethics and help insurers understand the repair process. After each class, attendees venture back to the shop for a tour.

“It’s a good way to get them to understand what’s going on in the business,” said Schoonover. “This was one of the things we could do to get to know the agents in the area and actually have something that’s worthwhile instead of doing the usual sales call. We wanted to be more than that.”

Expanding Services

As its name suggests, Schoonover Bodyworks & Glass provides expanded services, such as glasswork and detailing, which offer extra incentives for customers to return to the shop.

“If we have a really good customer, we’ll give them the works for free,” Schoonover says.

The shop also offers discounted oil changes for less than $20, allowing customers to maintain their vehicles without breaking their budgets.

In addition, Schoonover Bodyworks & Glass is a Volkswagen-Certified Collision Repair Center. Schoonover chose Volkswagen as a strategic business move, since the average American isn’t driving a Jaguar or another high-end make.

Schoonover sees becoming a manufacturer-certified repair center as a long-term investment. While he must purchase all-new equipment to meet Volkswagen’s standards, he believes it will pay off in the long run.

“It’s the way the industry could potentially be going, with more certifications from OE manufacturers, and I wasn’t going to miss that opportunity,” he says.

“It’s the way the industry could potentially be going, with more certifications from OE manufacturers, and I wasn’t going to miss that opportunity,” he says.

Expand and Strengthen

It seems that Schoonover Bodyworks & Glass will only continue to expand and strengthen its practices. And while Mike Schoonover is offering more services than his grandfather did, he says that it’s not all about glitz and glam.

“Keep it simple, honest and up front,” he advises. “It’s how we operate every facet of our business on a daily basis.”

Rapid Repair

Adjusting to the needs of its customers and adapting to a less than healthy economy, Schoonover Body Works & Glass developed a “rapid repair” service as a cheaper alternative to restoring the vehicle to pre-accident condition and OEM standards.

“When the economy turned south, we only repaired [a vehicle] one way, and that was to restore it to its pre-accident condition and make it perfect,” Schoonover says. “And the No. 1 reason we weren’t having people come back was that it was too expensive.”

Schoonover listened to his customers’ requests and crafted a new service to better suit their needs. With the rapid repair option, customers can choose to lower their repair costs by having aftermarket parts installed or getting dents roughed out instead of having the repairer do a complete overhaul of the vehicle.

“Our closing ratio has gone up,” says Schoonover. “We’re probably fixing more things that we wouldn’t have fixed in the past. With this, [customers] know what to expect, and they’re pleasantly surprised by what it looks like.”