Do you know where the oil dipstick is located on a 1926 Cadillac? I didn’t either until I spent a week in Detroit last month.

For those of you who may have missed NACE | CARS this year, it was a great show. There was a lot of information provided to the attendees through seminars, training sessions, discussion panels, CIC, CCIF, MSO Symposium, Technology and Telematics Forum, Service Repair Leadership Forum, demonstrations and vendor discussions. NACE is more than just a trade show; it’s also an opportunity to get to know new people.

With everything happening during that week, the highlight of the show for me was…Gary.

Gary and His GT

As you walked onto the show floor, the first thing you saw was a large display of beautiful vehicles and a huge semi used as a car hauler. From high-end sports cars to quarter milers to classic vehicles, this year’s displays were really something to see. Included in this collection was a 2004 Ford GT. I took plenty of pictures of the car and walked around it several times, examining every detail. I was so blinded by the beauty of this red American muscle car that I almost tripped over Gary.

Gary was polishing his pride and joy, a Ford GT. As he was working, and I was drooling over his ride, I asked him a few questions about this rocket ship on four wheels. From the first word Gary said to me, I watched his eyes light up when he spoke about his car. The pride in his voice was unmistakable as he talked about how this car had eventually come into his possession, its rarity (no stripes) and how much fun it is to drive. Gary’s love for that GT – and all the cars in his collection – made me stop and appreciate just how deeply people love their vehicles. Gary is the reason why I love this industry so much.

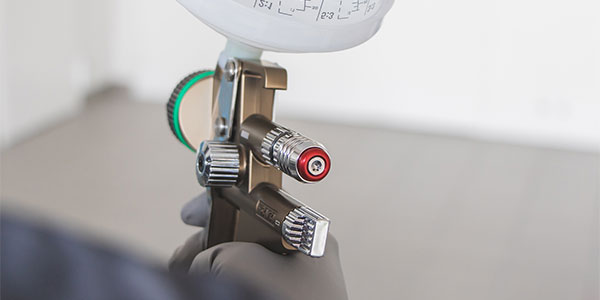

That glossy red caught my eye and my heart. The only way to deliver a quality finish like that on a GT in your shop is by using a spray gun. So, in this month’s How They Work, we’re going to talk about spray guns.

Spray guns are precision tools that deliver coatings to your customers’ vehicles and pride back to their hearts. Since it’s the paint that most people see first, spray guns are a critical part of the ability to deliver a flawless finish back to our customers.

EPA Compliance

By now, shop owners and painters should be well versed in the ins and outs of the EPA regulations covering the delivery of paint and materials to vehicles. However, if you’re just starting a collision repair business, you can read all about the EPA rules by visiting www.epa.gov/airtoxics/6h/6hpg.html. Another great source of information is the paint manufacturers, paint suppliers and spray gun distributors in your local area. Federal, state/provincial and local laws may differ, so it’s important to make sure you fully understand what’s required to be in compliance in your area.

In the event of an audit, you must have all of the proper documentation in place in order to prove that your spray gun is in compliance. On the EPA’s website, you can also find Spray Gun Equivalency Approvals for three spray gun manufacturers and several approved spray guns that meet the EPA’s requirements. Always ask the spray gun manufacturer for their EPA approval letter for the exact gun that you’re purchasing, even if you’re not currently in an EPA-controlled area. Someday, you might be in an EPA-controlled area, and this is one less thing you’ll need to worry about. Also, the EPA approvals for spray guns are only valid if the spray gun is used with all of the equipment outlined in the approval letter. For instance, if you replace an air flow control valve or pressure gauge on your gun with a different part number, your spray gun is no longer in compliance with the EPA’s rules.

Consistency

Throughout this series of How They Work articles, I continue to reinforce the need for sustainable and repeatable processes that are continuously refined. One process that should always be consistently repeatable is your paint process. A quality-built spray gun will go a long way to ensuring success in the paint shop.

Today’s quality spray guns are precision instruments. EPA rules mandate transfer efficiency of greater than 65 percent (at least 65 percent of the fluid being delivered is conveyed to the panel and the remaining is overspray or caught in the filters). EPA compliant guns either meet or exceed this requirement. While the different application types and the associated spray guns differ, one fact stands out: it’s less expensive to paint with a spray gun that delivers greater than 65 percent transfer efficiency than spraying with a less efficient spray gun. Look at your paint bill and tell me how important it is to get every particle possible transferred from the gun to the panel. Sure, you can save a few hundred dollars on a new spray gun right now, but you’ll spend thousands in overspray later on.

Along with greater transfer efficiency, high-quality spray guns are designed to deliver a finer atomization of the fluid. Fine atomization allows particles to sit closer together on the surface of the panel, and the fluid covers the panel comprehensively. You’re not going to get the same consistent coverage and fluid transfer efficiency using inferior products being sold at your local home improvement or freight stores. The last thing you want to see on your panels is irregular fluid patterns and differing droplet sizes.

Purchasing Considerations

Quality spray guns can be used for many years, so do your research up front.

First, you need to identify what you’re going to be applying to the panel. Manufacturers have different spray guns designed specifically for primer, color, mid-coats and clearcoats. It used to be that we would take an old color coat gun and then make it a primer gun at the end of its life. Honestly, there are those of us who still do this. However, you’re not going to get the best application of your primer coat out of a gun designed to apply color. The goal here is to get the best results from the least amount of work.

Once you decide on the purpose of the gun, go get a few different models in your hands. Actually, go pick them up and hold them. How do they fit in your hand? Is the weight appropriate for the length of time you’re going to be holding the gun each day? If you have a buddy spraying with a different gun across town, get your butt over there and get a good look at it. Not only look at it, but, if possible, ask to do some sprayouts to get the feel for how well you like it.

Another great source of information is your local tool distributor. These industry professionals can also help you choose the correct tool for the job. The level of support is something you just don’t get from home improvement or freight stores or online auction sites. Tool distributors can be your best friends, especially if you need a replacement part right away. So make sure you choose a reputable distributor representing a quality brand.

Let’s be real with each other for just a second. If you’re looking to buy a tool from an online source, new or used, you’ll be able to save a few bucks. You can even buy replacement parts online. But, at the very least, you’re going to lose the warranty for those items and the support from the manufacturer. Even worse, you could be investing in a counterfeit product that may only last a few months or more.

Speaking of warranties, make sure to understand the warranties of each product you’re looking to purchase. What’s covered and what’s not covered, as well as the length of the warranty, are important considerations. Don’t forget to ask about the cost of having your tool rebuilt when it comes time. What’s the cost and availability of replacement parts? Remember, you’re looking to determine the total cost of ownership of this tool, so ask lots of questions. The cheapest gun could actually end up costing you a lot more in the end. Don’t go buy tools based solely on the initial price alone.

Best Practices

The consensus in the tool industry is to use a separate spray gun for each product applied. If you’re still using your color gun to apply clearcoats, you could be adding unnecessary work to your paint process. No matter how well you clean your guns, at some point you will inadvertently have some color get into your clearcoat. Separate your guns and designate their purposes. This takes one more variable out of the mix that could cause you additional time and aggravation.

When spraying product, make sure you know the correct needle, cap and nozzle sizes required for the products you’re using. Faster or slower drying products will affect your gun configurations. Humidity plays into this as well, so be prepared to make those adjustments as necessary. Use the correct application distance between the spray gun and the panel. Avoid over-applying product or sending unnecessary overspray into your booth filters. Applying primer, color, mid-coat and clearcoat applications are as much a science as they are an art form.

Two areas we struggle with in the collision industry are ongoing training and routine equipment maintenance. Sure, you’ve been spraying paint for years and you think you’re pretty good at it based on your experience. But getting a refresher course on a piece of equipment, training on new product options and making sure your tools are operating at 100 percent efficiency are the things that separate you from a backyard hack. Don’t be afraid to dedicate some of your time to training and routine maintenance. It will pay off more than you know.

Everyone has their own method of caring for spray guns. However, the best practices are that you should clean your gun every night, using a blow dryer to dry it. Avoid leaving your gun in solvent overnight, as it is hard on the gun and will contribute to premature maintenance cycles (i.e. having to replace parts and having it rebuilt more frequently). Avoid using any harsh chemicals to clean your gun as they’re also hard on the spray gun’s components.

By using best practices, equipment manufacturer recommendations and paint manufacturer and supplier guidelines, you’re setting yourself up to deliver a great product to your customers on a consistent basis. A lot of hard work goes into making sure the first thing the customer sees is a perfect finish. Shortcuts here will eventually land you a ton of redos. The worst part is that you may not see these redos for years and then…you get the picture.

Conclusion

After Gary was done talking about the Ford GT, he casually walked me over to another masterpiece in his collection, a 1926 Cadillac. By now, he’s beaming from ear to ear as he’s telling me all about his barn find. This car, which is all original, including the convertible top, still runs. Gary said that he drives it on occasion, which makes me so happy to hear. Beautiful cars should be driven.

It’s also important to know how to check the oil level on a 1926 Cadillac when you decide to pull it out on a sunny afternoon. The oil is checked using a float indicator to display the oil level, which is mounted on the top of the passenger side of the engine block. There is no oil dipstick. And that’s another reason why I love going to NACE | CARS every year.

Contributors to this article include Tony Larimer, director of sales and marketing – Dan-Am Company; Nicolle Williams, marketing manager – Anest Iwata; and Tim Keating, vice president – Motor Guard Corporation. Special thanks goes to Tom McGee, business development.