Color is art. Color is science. Color is emotion. Color is complex. And to every person from the automaker to the auto owner, color is very important. In fact, there is so much that goes into color design and color selection today that automakers have legions of people devoted to intricate and complex color design. And as OEM colors become more intricate and complex, the challenges of repairing them increase. Read on to learn about new technology that helps streamline the refinishing of some of the most eye-catching and complex colors on the market – translucent colors.

What is a translucent color?

You know it the minute you see it. Translucent colors have an irresistible depth and clarity of color that draws in the eye. Think about looking into a piece of Jolly Rancher™ candy. Translucent colors (often called candy colors for this very reason) have depth for miles so you almost feel like you can swim in them; and they take paint appearance and beauty to a remarkable new level. Translucent colors were first developed in the 1950s, but until recently, have not been widely used by automotive OEMs. Today, translucent colors are also known as OEM factory tri-coat colors. A few of the most well-known translucent colors on the market are Ford’s Ruby Red and Mazda’s 46V (see photo).

Why are translucent colors so vibrant?

Translucent or tri-coat colors appear so intense because light passes through the paint, reflects off a metallic base color, and passes through the paint a second time before the eye actually sees the color. This is what causes a legitimate translucent paint job to look far more vibrant and attractive to the eye than conventional paint jobs. Let’s dig deeper into the process it takes to replicate this astonishing look.

A specialized process for sure

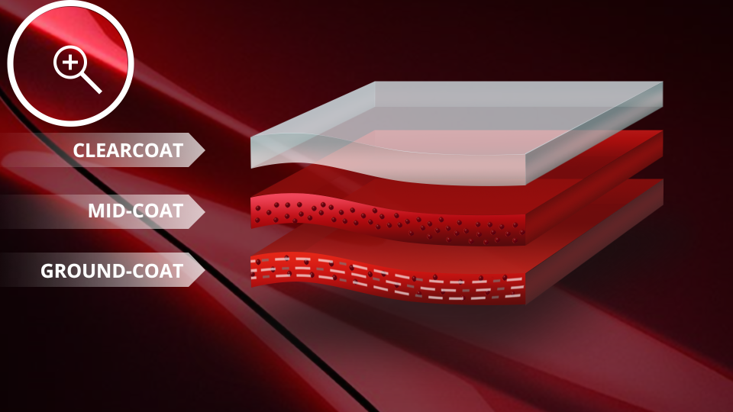

The technology needed to replicate the OEM translucent colors in a repair scenario requires the use of a mid-coat layer composed of special pigments. These pigments add to the perception of depth within the paint film and recreate the original paint appearance.

But first, the body of the car or other object to be painted must be finished as perfectly as possible to avoid visible problems in the final finish. After the panel is prepped for paint, the first layer called the foundation or ground-coat is applied. Typically, the foundation is a color that will complement the translucent mid-coat and produce a brilliant effect when it is applied. The key with this first layer is to reflect as much light as possible. Then the translucent (let’s say we’re doing red) paint is applied on top of the reflective paint. This red paint is transparent and can require many coats or layers to achieve the proper depth and richness of color. Once the translucent red color reaches the proper appearance of depth and color intensity, multiple coats of clearcoat or topcoat are applied to protect the paint job and add to the feeling of depth of the paint. As you can imagine — and many have experienced — these amazing translucent colors can be quite challenging to not only replicate but to color match.

Replicating the look with fewer steps

But wait! What if you could shorten the process and achieve the same knockout translucent look more quickly using fewer coats (saving time and money) and achieving a bang on color match? You can!

There are new translucent toners on the market by the global coatings company, AkzoNobel. The key to these translucent toners is that they reduce the number of mid-coat layers required to achieve color density and accuracy because they contain specialized, proprietary pigmentation. And besides potential savings in time and materials, painters have reported a greater ease in color matching with these new toners, again saving time and money. One of the brands offering this pioneering technology is Sikkens Autowave 2.0.

“Sikkens Autowave 2.0 has translucent toners that allow me to skip a tinted clearcoat and have superb blendability, even on the tough colors,” says Brian Livingston of McCarthy Auto Group in Olathe, Kansas. “Sikkens Autowave 2.0 glides on with ease, and the proprietary technology they use definitely increases production. The most important benefit to me is the unparalleled ability to mix and match paint to OEM and customer expectations. I get the color match right the first time, every time.”

There you have it! If you are interested in learning more about replicating translucent colors with greater ease and accuracy, contact your local Sikkens representative or visit www.sikkensvr.com.

This article was sponsored by: AkzoNobel Coatings Inc.