One of the most common repair needs emerging in today’s shops involves spot welding, or squeeze-type resistance spot welding (STRSW). BodyShop Business caught up with Brian Wasson, manager, I-CAR Program Delivery, to learn more about this repair technique.

BodyShop Business: What is spot welding?

Brian Wasson: One of the most prevalent challenges our I-CAR instructors encounter during training events is variances in terminology. The most common variance is plug welding and STRSW or spot welding. Technically speaking, they are not the same, but many use these two terms as if they’re the same.

MIG plug welding or plug welding is a process in which two or more mating flanges are attached by filling punched or drilled holes with molten filler metal using gas metal arc welding (GMAW) equipment. This process is considered common practice among collision repairers. However, within original equipment (OE) repair information, this process has become less common. To produce quality plug welds, one must have a refined technique and skill to achieve the proper amount of penetration without overheating the material. In our training and certification programs, our instructors provide one-on-one coaching to enhance these techniques and skills.

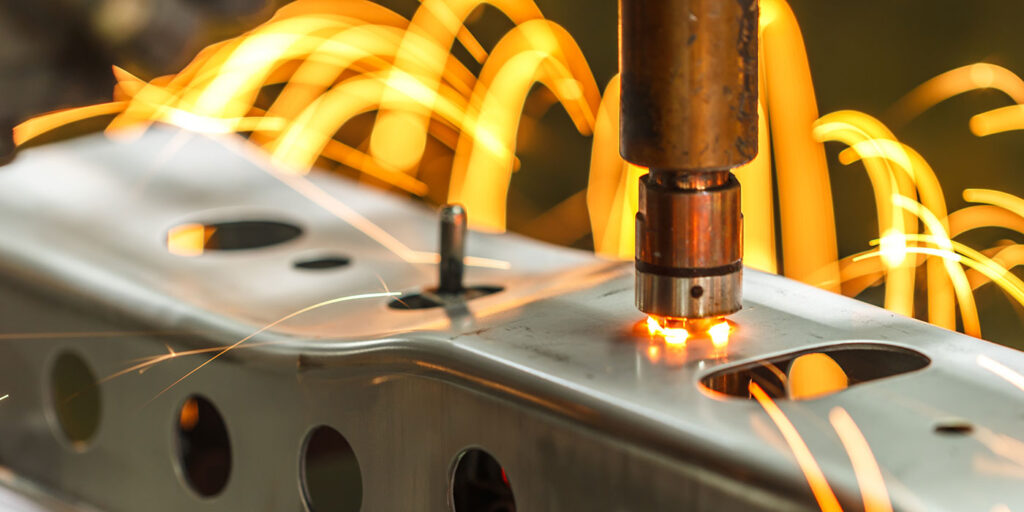

While STRSW involves attaching two or more mating flanges, it does not require punched or drilled holes in the mating flanges. In this process, two electrodes squeeze the mating flange at a high pressure and apply high amperage to create a weld nugget. The equipment used for this process is very specific and typically requires specific (three-phase) infrastructure to operate.

BSB: Why is STRSW becoming a popular recommendation by automakers?

BW: With each new model year, original equipment manufacturers (OEMs) strive to meet consumer demands for more advanced features and higher safety ratings while attempting to achieve better fuel economy. Every advanced feature and additional safety system adds weight to a vehicle, which affects fuel economy. One method OEMs utilize to reduce overall vehicle weight is the use of higher-strength steels because they can achieve their designed over-the-road and collision performance with these lighter steels.

There are many types of steel available to vehicle engineers, each having its own unique characteristics. These steels have one thing in common: Heat effects their strength. Since STRSW allows steel parts to be attached with minimal heating of the parts, it’s an ideal choice for OEMs to use in the manufacturing process. Traditional methods like GMAW (MAG welding) achieve the attachment of the panel, but the process requires the steel parts to become very hot, which may change their characteristics and affect the intended collision performance of the vehicle.

BSB: What precautions are needed when spot welding around ADAS components?

BW: OEMs will provide guidance on precautions when welding during the repair process. These precautions are typically located within the general repair information of the repair manual. In my experience, precautions specific to advanced driver assistance system (ADAS) components are similar to any electronic system or module, involving the removal of modules, sensors and wiring harnesses from the vehicle. In some cases, the component is located several feet from the repair area and involves additional disassembly. It’s a best practice to develop a repair plan early in the repair process so these needed actions can be identified right away.

The reason why OEMs provide these specific precautions is because a by-product of any welding process is the creation of a magnetic field, which can introduce voltage into the vehicle’s electronic systems and damage them if precautions are not taken. Since STRSW is a high-current process, this magnetic field can be very large. You may have noticed the welding machine’s cables move or jump when the machine is triggered and nearby metal objects becoming magnetized, which is physical evidence of the presence of this magnetic field.

BSB: Is there a metal particularly recommended to spot weld?

BW: Typically, any hot stamped (or boron) alloyed steel requires STRSW; however, STRSW may apply to any steel. It is common for outer replacement parts to be low-strength steel, and those get welded to the inner panel, which is a high-strength steel.

BSB: Where does welder technology stand today?

BW: We’re fortunate these days with STRSW technology. A common feature of modern welding equipment is its ability to automatically set the machine’s parameters to achieve a quality spot weld and preserve its characteristics. However, we encourage repairers to learn the manual method, as some OEMs will require specific clamping pressure, hold time and amperage in specific areas of the vehicle. When this is needed, these “smart” welders need to be put into manual mode to properly apply the weld.

BSB: How critical is training?

BW: STRSW is procedure-based and, as with any procedure, if a step is skipped or not executed properly, it will affect the result. Our hands-on training program focuses on executing procedures and brings verification of specific steps that equip the repairer with the necessary knowledge and skills when performing STRSW. We conduct our training in-shop using the same equipment the repairer utilizes for collision repair. Also, we help repairers understand shunting and material coatings to achieve successful welds. It is common (and expected) to encounter application issues, and our instructors have been trained on how to identify and correct issues.

I would also recommend that repairers receive training specific on their equipment, because having the right tool is one thing but knowing how to use the tool correctly is everything. Every equipment manufacturer I’m aware of has a training program for their equipment and, in some instances, they partner with I-CAR to deliver this training. Ask your equipment supplier what training programs are available.

BSB: Why is it important to follow OEM welding guidelines?

BW: The only way to ensure “as-built” collision performance is preserved is to follow OEM repair information. A common issue repairers have with OEM repair information is interpreting the information, and in my experience, the best way to overcome this challenge is to receive training and, most importantly, implement lessons learned in their everyday operations.

BSB: How critical is maintenance?

BW: All equipment within every collision repair facility is a tool, and production environments utilize these tools on a regular basis. These tools need regular maintenance to not only keep them in running order but also to prolong their life. Reference the owner’s manual for maintenance needs, and if you cannot locate the manual that came with the equipment, look online, as most equipment manufacturers make the owner’s manual available via their website.

There are two commonly missed regular maintenance items we encounter in our training events. First is the condition of the electrode tips, which become flattened over time and either need to be redressed or replaced. These tips are considered consumables and are expected to wear out over time. Another is condition of the equipment’s internal coolant; this liquid coolant needs to be replaced regularly and, if kept in good condition, will prolong the lifespan of the equipment.