A generation ago, we learned that the old way of straightening frames was obsolete and downright dangerous. We discovered that applying heat to HSLA (high strength low alloy) steel would turn the critical metal into mild steel, thus reducing its strength and negating the structure’s ability to manage collision forces. While this created a new paradigm in collision repair, it was merely the tip of the iceberg when viewed through the lens of contemporary collision repairs and automotive construction.

Optimizing Steel

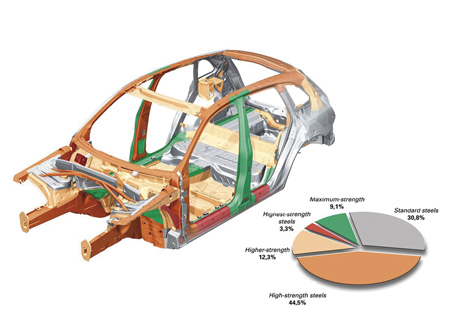

Steel constitutes over 55 percent of a vehicle’s mass. While the use of composites and aluminum has increased over the years, the development of ultra-light steel alloys permits the use of less material without sacrificing strength and safety.

Research efforts by the Ultra-Light Steel Auto Body (ULSAB) project demonstrate the attempt to optimize the use of steel in automobile design. Also of importance are efforts to develop new high-strength steels as replacements for carbon steels. The ULSAB consortium is made up of steel manufacturers from 18 nations that have produced a vehicle concept body that weighs 25 percent less than an average sedan sold in the U.S. ULSAB uses of tailored blanks, which are single pieces of steel formed into a uniside that vary in thickness. The vehicle designer is able to select different steels based on their performance, strength and weight and stamp them into one structural component.

Strong vs. Mild

But what are the stronger steels and how do they react differently than mild steel? Understanding high-strength steel requires understanding the meaning of tensile strength. Tensile strength is the resistance of a material to a force tending to tear it apart, measured as the maximum tension the material can withstand without tearing.

Steel is an alloy made from iron combined with carbon, the percentage of which determines the grade. Carbon acts as an agent to harden the steel, although other elements such as manganese, chromium, vanadium and tungsten can also be used. The more carbon that’s used, the harder – but more brittle – the steel becomes. Tensile strength increases with the addition of carbon to the alloy.

In ongoing efforts to reduce the weight of a vehicle to increase fuel efficiency, the use of hybrid steel alloys has increased exponentially. In 1975, the federal government imposed CAFE (Corporate Average Fuel Economy) on automakers, which mandated fuel economy on vehicles. Subsequent increases in CAFE demands made automakers rethink the body construction in terms of its materials and build methods.

Less Total Losses?

A recent study conducted by World Auto Steel, a subsidiary of the World Steel Association, communicates the value of steel in automobiles to industry and society. A statistic often seen in the media indicating that weight and fuel consumption have a direct correlation is that a 10-percent mass savings can result in a 6- to 8-percent reduction in fuel consumption. Lighter vehicles doesn’t just mean advantages in fuel economy and performance, but also a reduction in the amount of structural damage since less mass creates proportionately less kinetic energy that’s carried into a collision. And, of course, that could mean less fewer losses.

Oliver Hoffman, head of Sales/ Engineering Technology at ThyssenKrupp Stahl AG, spoke recently about steel and the processes his company is pursuing to continue the industry’s environmental performance improvements. Hoffman says that while aluminum will exceed steel’s weight savings by 15 to 20 percent, it will also exceed the cost of steel by 60 percent. Hoffman also points out the production of aluminum for use in vehicles will create a greater carbon footprint than the production of steel alloys.

Despite the introduction of a host of metals outside of steel, steel is undergoing somewhat of a renaissance, says Jody Shaw, manager of Automotive Marketing at U.S. Steel Corporation. Shaw says steel has benefits from a life cycle assessment and environmental basis. Due to its recyclability (steel can be recycled time and time again without loss of quality), steels gives a steel-maker a 70-percent cost advantage over raw ore. Based on a life cycle analysis, Mercedes Benz recently switched composition of their engine cradles in the C class series from aluminum to steel.

Lighter and Stronger

Aluminum, which has been the metal of choice of makers of performance autos and aircraft, has been used extensively in lightweight bodies. Sir William Lyons and his partner, William Walmsley, used aluminum in the production of motorcycle sidecar bodies, most notably the Swallow sidecar, the forerunner to the Jaguar motorcar. Lyons went on to produce the Jaguar sports cars and enjoyed a string of victories in the Le Mans races during the ’50s.

Today, the Jaguar XJ sedans are made exclusively from aluminum, use epoxy adhesives for panel bonding and feature more than 3,400 self-piercing rivets per car. The resulting vehicle is 440 pounds lighter and 60-percent stronger than its steel predecessor. Its fender apron shock towers are cast assemblies that rival their steel counterparts in rigidity and strength.

Because of their lightweight properties, automakers to use aluminum materials more for affordable weight reduction applications and high-performing, low-investment construction methods. The Audi R8, Ferrari F430, Lamborghini Gallardo and Jaguar XJ8 are aluminum-intensive vehicles in production.

Crash Performance

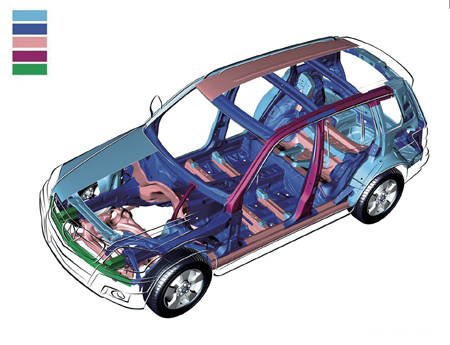

Automakers continually work to improve their vehicles’ crash performance. Over the past several years, the global steel industry has undertaken several projects with the goal of demonstrating the use of the newest generation of advanced high-strength steels to reduce vehicle mass and improve crash and structural performances at affordable costs for high-volume production.

A body panel has an outer, contour-defining component and an inner structural component. The inner structural component comprises a front member (also known as a frame rail), a rear member, a number of side members and a central region defined by the front, rear, and side members.

The outer component is secured to the inner structural component at the outer edge of the panel. In addition, the outer component can be continuously adhesively bonded to each internal member, to flanges of the front and rear members, to each cross member and to the upper surface of each side member. The resulting panel is lightweight, has a high degree of rigidity, is capable of absorbing crash energy in frontal impact, and is resistant to “oil canning.” The fender apron has side members that form a structural interface with A pillars to facilitate load transfer in a frontal impact.

Nearly all vehicles today are made of steel because it’s economical and makes for safe vehicles. Steel has the unique and inherent capacity to absorb an impact and diffuse crash energy. High-strength steel can be engineered to collapse like an accordion.

Steel also has the tendency to become harder when it’s crushed, which means it will become stronger on impact, allowing it to absorb more energy, an effect is also known as work hardening. Most modern vehicles use new generation, advanced high-strength steel, which will make a car not only safe but also stronger and more fuel-efficient.

Identification

The task of identifying steel substrates can be daunting, depending on OEM information available to body shops. Mitchell International, one of the leading information providers to the collision repair industry, has developed an online repair standards and metal identification resource. While it’s dependent on the OEM for its source of data regarding car construction, the Mitchell Information Center is a fairly simple process for identifying metals used in vehicles.

Using either the Mitchell Information Center’s VIN decoding feature or its drop-down menu to select a vehicle, one can select the “Repair Standards” feature on the program and then go to Metals to identify the various composition of a car. The section you’re directed to will provide you with detailed diagrams showing the location, handling and cautions associated with the repair and or replacement of high-strength steel components.

One thing is certain and crucial to the survival of body shops: Vehicles will crash. While none of us want to see more traffic accidents and injuries and hope that we won’t ever be in one, accidents do happen. Be prepared to deal with advancements in auto body construction so that you can safely repair your customers’ cars and trucks.

Writer Charlie Barone has been working in and around the body shop business for the past 35 years, having owned and managed several collision repair shops. He’s an ASE Master Certified technician and a licensed damage appraiser, and has been writing technical, management and opinion pieces since 1993. Barone can be reached via e-mail at [email protected].