With all the refinements and advanced technology built into today’s vehicles, it’s amazing how technicians, estimators, production managers and parts managers can keep up with the changes and correctly restore vehicles to a safe and accurate condition.

If one continues to repair vehicles with outdated practices, parts and procedures, the completed outcome may ultimately affect the integrity of the vehicle if it’s involved in another collision. While old habits are sometimes hard to break, we as industry professionals need to look at the way we evaluate and repair vehicles. We all want to deliver a complete, safe and properly repaired product to our customers, but without access to up-to-date repair procedures, equipment and tools, we may be cutting ourselves short.

While many collision repair facilities have undertaken the necessary steps to keep current with vehicle technologies, others feel that certain investments may not be in the best interest of their businesses. But investment in a tool that can ultimately enhance profitability is the first step in the right direction.

Ask yourself:

• Which tool will ultimately provide true value to my business?

• Which tool can increase efficiencies and productivity affordably, while allowing for future modifications and updates?

• Which tool can affordably provide me with an added source of untapped income that I may not have thought of?

I believe that the best tool available to repairers is accurate and up-to-date repair procedures. I also believe that referencing this information should start in the planning stage.

Technical Service Bulletins (TSB) are just one benefit of manufacturers’ repair information. They’re a tool within a tool that allows us to keep up with ever-changing technologies. Here’s an example of a TSB that describes an improved method for removing the engine undercover on certain Mazda vehicles.

Application

2004-2009 Mazda3 (including Mazdaspeed3)

2006-2009 Mazda5

Some technicians may feel that removing the undercover is hard and takes too much time. They may even break it when removing it. This TSB points out undercover removal points when it’s difficult to remove.

Required Parts

Clip-nut – BR5S-56-496

– Quantity: 7

– NOTE: Right and left sides; front side 3

Bolt – 90720-0620

– Quantity: 0-7

Service Information

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials, and removal and installation procedures. Always refer to the vehicle manufacturer for questions relating to applicable or non-applicable

warranty repair information.

Repair Procedure

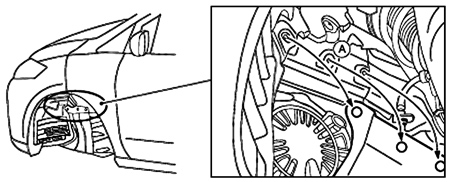

1. Detach the splash shields on both sides from the front frame (A) joint (Figure 1).

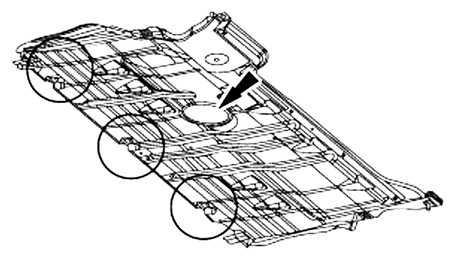

2. With the undercover hanging down, remove the bolts from the front side of the undercover (Figure 2).

NOTE: Put your hand through the hole on the undercover or from the rear-end of the undercover, then grab the clip-nuts using a wrench and remove the bolts.

3. Remove the splash shield and the undercover from the vehicle.

4. Using a wrench, hold the clip-nuts (on the right and left sides) and remove the bolts, then separate the splash shield from the undercover (Figure 3).

NOTE: Be careful not to damage the undercover.

5. Replace the original seven clip-nuts with new ones (BR5S-56-496).

6. Before installing the bolts, apply lithium grease to the bolts. If the original bolts are too rusty to be reused, replace them with new ones (90720-0620).

7. Re-install the splash shield and undercover to the vehicle.

NOTE: This repair/service procedure is excerpted from a TSB published by the vehicle manufacturer and is intended for use by trained, professional technicians with the knowledge, tools and equipment to do the job properly and safely. It’s recommended that this procedure not be performed by “do-

it-yourselfers.”

Dan Espersen is the ALLDATA Collision Program Manager, a Gold Pin Member of the Collision Industry Conference (CIC) and holds an AA Degree in Automotive Technology. He has 17 years of experience in the collision industry and 17 years of experience in the automotive industry.

© 2009 ALLDATA LLC. All rights reserved. All technical information, images and specifications are from ALLDATA Collision. ALLDATA is a registered trademark and ALLDATA Collision is a mark of ALLDATA LLC. All other marks are the property of their respective holders.

© Mazda, Mazda3, Mazdaspeed3 and Mazda5 are registered trademark names and model designations of Mazda North American Operations. All trademark names and model designations are being used solely for reference and application purposes.