Air compressors. They’re the heart of your shop, pumping blood to all vital areas and making everything work. They quietly do their work on a daily basis, reliable and hardworking.

Air compressors. They’re the heart of your shop, pumping blood to all vital areas and making everything work. They quietly do their work on a daily basis, reliable and hardworking.

Assessment

Just like any piece of equipment, with compressors, you have to assess the needs of your shop today and also where you might be in the future to select the right one for your shop. For example, if you have plans to go low-VOC or waterborne anytime soon and are considering air movement devices operated by your compressed air system, you’ll want to plan for that right now.

So, when it’s time to get rid of your 30-year-old beast, you could be making a major faux pas by going with the same old technology. You may be blindsided and intimidated by the homework you’ll have to do to find a suitable replacement, but with a little effort, we can examine your shop’s real air delivery needs.

Audit

You can find a manufacturer representative to conduct an audit of your existing air compressor – its duty cycles, energy usage, pump-up tests, etc., to help you determine the real cost of your current system. The real cost of your old versus new air compressor is not just the purchase price but is a calculation of the total cost of ownership. This includes energy usage, maintenance, replacement parts, etc. However, don’t count out the fact that redos are a part of this equation.

The audit should last a minimum of a week, however, you should get an entire month’s worth of data under your belt during a typical production month. If January is your slowest month, don’t schedule the audit then because you won’t get the proper readings you need.

Determine the amount of cubic feet per minute (CFM) and the amount of pressure per square inch (PSI) you’ll need. This is important because oversizing your air supply can cost you on your electric bill.

Design

When reviewing your air delivery system, remember the following: Your air delivery system must have enough clean, dry and stable air pressure to meet your maximum needs.

We have a ton of particulates floating through the air all the time in our shops. Make sure that you and your manufacturer include more than adequate filtration systems – air intake filters, dryers, oil separators, particulate filters, coalescing filters, etc. Also, if you’re spraying waterborne, you have a much lower humidity threshold that has to be filtered out versus a shop that’s still spraying solvent-based paints.

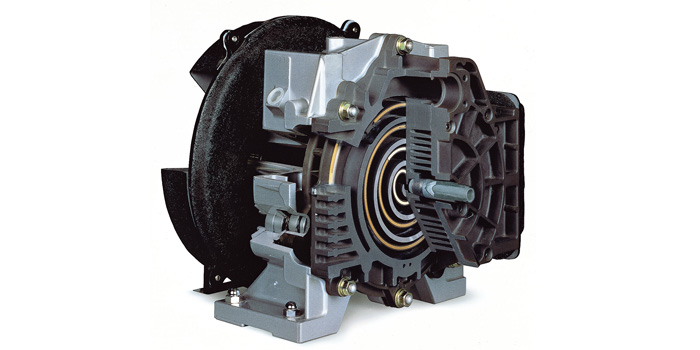

Many of us use oil-lubricated air compressors, which carry over a small amount of oil into the compressed air. Depending on the technology, the amount of oil in your compressed air could become a concern if you’re a shop that’s looking to eliminate as many defects as possible. As the older piston air compressors age, their piston rings wear as well. As those tolerances widen, you should expect to see more oil particles being delivered to your shop and your spraybooth.

Manufacturers now have options that include oil-free air compressors. Oil-free air compressors are used in the medical, food services and other industries that have a need for oil-free air streams.

Location

Another overlooked item is the air compressor’s location in the shop. Moving the air compressor outside will remove the noise from the facility, but could reduce its service life. Allow enough space so that the system can be easily accessed for servicing. A clean environment is recommended for the air compressor to reduce the amount of external debris that may buildup on the air compressor equipment. This debris can raise the operating temperature of the equipment and reduce its cooling efficiency. Don’t forget to account for proper ventilation of the area to remove excess heat appropriately. In the wintertime, that heat can also be reintroduced into your shop to help offset cooling costs.

Warranties and Maintenance

Warranties range from one to 10 years and everything in between on a new air compressor system. Ask about the warranty up front before the purchase, not after you’ve signed the paperwork and it has been delivered. Be aware of extended warranties that are tied to maintenance contracts. I’m not opposed to maintenance contracts, just go into your negotiations with “out-the-door pricing” in mind that includes the maintenance contract. Also, not everything is covered under the manufacturer warranty, so just be aware and have non-covered items listed for your reference.

Even if your warranty is not directly tied to a service contract, you need to get the air compressor and the rest of your equipment on regular service schedules. Servicing everything regularly will ensure your equipment continues to operate at peak performance. Don’t forget that best practices state you should be taking a look at your air compressor weekly to check for any maintenance issues and to look it over. The last thing you want is to be looking for a service tech to come out and fix your compressor on the busiest day your shop has seen in years.