It was the early ’80s — hair bands and Valley girls and more than a few mullets. Still, it was the perfect time for Jim Beck to fall in love — with a 1976 Mustang Cobra II.

The Mustang was spotted by a friend, who knew Beck liked a “good challenge” when it came to fixing sports cars such as Mustangs and Camaros — but liked doing so without investing big money.

“When I first saw her, I saw what she could be, not the shape she was in,” says Beck, a sales/service/tech support consultant who lives in Ridgefield, Conn. “You see, some people look at things as a problem. I always looked at things with a solution. I was young, full of piss and vinegar, and more so, was bored with no challenge at the time.”

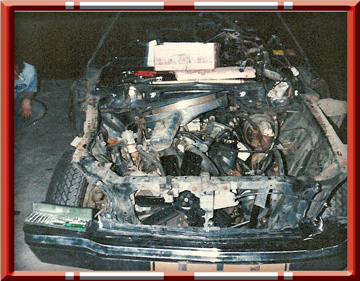

At the time, Beck was a painter in New Jersey and borrowed the cash — as advanced pay from his boss — to bring the car home. For $700, the Mustang was his. Since he already had some of the parts — a bumper, a cracked header panel and a headlight door, he considered himself ahead of the game in the repairs.

In reality, he had no idea what he was getting into.

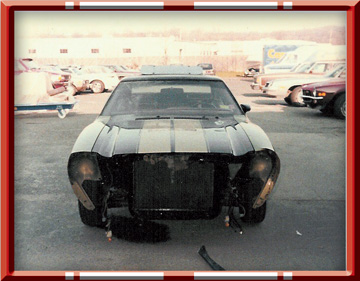

Slowly but surely Beck spent a good part of his paycheck and an even bigger part of his nights and weekends on what we’ll dub “Black Beauty.” (Beck and his friends had a more colorful name for her — a name that we can’t print here.)

Turns out, he should’ve nicknamed her the “Black Hole,” considering she sucked him dry financially.

“She loved me, but was killing me slowly, money wise,” says Beck.

Even after countless hours of work and countless more dollars, there was a point in the repair process where Beck considered cutting his losses and junking the car. And he knew the repair was about to become even more costly because the right frame rail and suspension were twisted up badly. That’s when he called in reinforcements.

The reinforcement’s name was Ziggy.

Ziggy — a friend whose “old school” teaching eliminated the odds that the car would “go down the road sideways” — helped Beck straighten the frame, the right apron and frame rail.

After all was said and done, Beck’s not sure how long it took to finish the work on the car or how much it cost him (he lost track). He does know it involved a lot of busted knuckles and late nights.

“Thank God I had a boss who preferred having me come into work the next day tired [versus] all hungover, which is why he let me work on my own car in his shop,” he says.

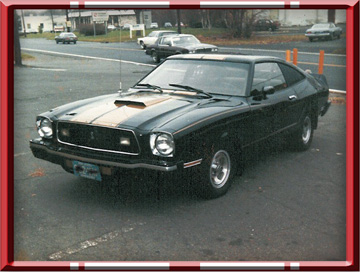

Once the work was finished, Beck took her out to the local hang out on Friday nights and parked her right under a parking lot light to show her off. She was no race car, he says, just a “looker.”

Just six months after he finished restoring the car, Beck sold it. He says it was hard to do but necessary after the investment he put into restoring her.

“That was my art work but, like most artists, we gotta eat,” he says.

But at least he had the peace of mind knowing that someone else was taking good care of his art work, right?

Not quite.

As it turns out, the buyer eventually blew the nose off the car again in an accident, brought it back to his shop and even asked Beck if he wanted to buy it back … cheap.

“ ‘Once is enough,’ I told her, and to this day, I’m sure she still doesn’t know what I meant.”