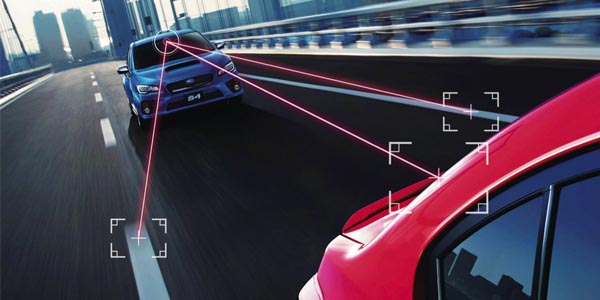

What is the value of all the electronics being developed and implemented in today’s and tomorrow’s vehicles? In studies done by government and insurance industry entities, the stats tell a story of success in reducing severity in crashes with vehicles equipped with advanced driver-assistance systems (ADAS). With this success, expect more vehicles to feature this equipment as new models roll out. Repair procedures will change as new features and sensors are added that make ADAS better or more efficient.

The reality is that vehicle repairs have taken on a whole new twist. Most people resist change and have a difficult time accepting it. I hear so many repairers complain, but I’m also seeing many turning change into opportunity. What will you do?

The Dilemma

Electronics in today’s vehicles require specialized tools to diagnose and calibrate. This has created a problem as the majority of body shops have not had to deal with computers, sensors and sensitive electronics. At most, body shops have dealt with a simple broken wire or damaged connector.

In the mechanical repair of vehicles, computers and their diagnostics were much more common. Mechanics have been exposed to the computers and the changes they bring for decades now. This is a whole new ballgame. There is more to these computers and their sensors than just reading DTCs or flashing codes. We now know scans along with aiming of the sensors for recalibrations is a critical step that must not be overlooked. This is after we verify that all physical damage is correctly repaired. Pre-repair scans, post-repair scans and recalibrations are now a part of mainstream repairs for body shops. This will be either a hindrance or boom, depending on your approach.

Learning to repair these new systems and what is needed requires some research. In reality, a lot of research. Once you’ve completed all that research, you’re going to be presented with some choices:

- Send the vehicle to the dealer for diagnostics and recalibration

- Hire an outside company to come to the shop for all electronics services

- Sign up with a company that scans and connects to the internet

- Buy the aftermarket equipment needed

- Buy OE tools

- Use multiple choices from the list above

No matter what you choose, there is a benefit to any shop. You need to have a plan. Operating by the seat of your pants will cost you time and frustration, not to mention money. No matter which way you look into these repairs, there is an opportunity for increased revenue. I know that requires a higher severity of the cost of repairing a vehicle, too, but you need to see the big picture.

The cost of injuries or bodily injury increases each year. These devices are proving they can reduce severity in a crash, which also includes bodily injury costs. The cost of these electronics can result in some of the most beneficial safety improvements we’ve seen. In reality, the need to service these systems will only increase. How you control costs and market your shop’s services or abilities will be a determining factor for choice of shop in the very near future. The learning process may be an interesting road, but it could be very well worth it.

Success at a Cost

We all hear and see so many negative issues, but I’ve experienced some success stories too. Don’t get me wrong, they worked through some issues and are still working through them, but these shops were determined to get control of the issue of scheduling and time to diagnose and repair the electronics. The one thing these managers and shop owners did was evaluate their resources. To arrive at a solution for your shop, you need to look at all possibilities. You need to be honest with what you have available to you in time and resources.

Shop needs. What abilities do you have to have? Pre-repair scan, post-repair scan, recalibrations, chasing wires. These are the abilities you must assess. Pre-repair and post-repair scans can be done with scan tools. Recalibrations may need targets. Chasing wires is the ability of a technician to repair or find what is causing codes or DTCs. The DTC most likely will need more than just clearing the code.

Capital. How much operating capital do you have? The cost of equipment can be very high. You need to look at your return on investment and over what time period.

Personnel. Someone will need to be trained on scanning and recalibrations. Many new vehicles require a pre-repair scan or post-repair scan. The reality is that every vehicle in the future will need some service of this type. A small shop as well as a large production facility will need to dedicate precious time and resources to each vehicle. These vehicles will also require more extensive test drives after completion of repairs, which will also require more personnel and time.

What is your repair focus? Does your shop work on new vehicles? By new I mean vehicles within one year of their release date. What percentage? What models? What percentage of work is older models, as in older than one year from their release date.

Which dealers are within range of your shop? What are their capabilities and costs? Price out the cost of a scan. Now, price out a recalibration of the part (such as a windshield) as they are two entirely different services.

Shop space. Do you have the space to do the scanning process? This is usually just the space for the vehicle. Do you have space for recalibrations? This requires up to 20 feet in front of the vehicle on a level surface with a background and lighting that won’t confuse the cameras or sensors.

This is a basic list as every shop has their own unique variables. A shop needs to look at all these variables to make an informed decision.

The Value of Options

Dealerships are mostly a good choice for scanning and recalibration services as they can service any year of vehicle, even brand new. Updates for scan tools usually hit them first months ahead of aftermarket tools. If the dealership service manager has done his job, the technicians should have the proper tools and training. This is especially true with scans, but I’ve found that some dealers are not well-versed on recalibrations. You would interview a technician before they worked for you, so now it’s time to interview the dealers you work with to make sure they know what they’re doing when it comes to scanning and recalibration. Sometimes you may be educating them!

One drawback to using dealers is having to transport the vehicle to the dealer and back. People and time is a big consideration. The time a vehicle sits at a dealer on their schedule can be controlled by a repair shop’s scheduling practices. The impact on cycle time has to be considered in all decisions.

In some situations, such as recalibrations for windshield replacement, dealers may require OE glass. The auto glass replacement industry has learned a hard lesson on the differences in OE and aftermarket glass. Factors such as bend and clarity of glass and bracket placement on glass for cameras has a significant impact on recalibrations. Even the Insurance Institute for Highway Traffic Safety has weighed in on this issue. Remember, even if components are not disconnected from the vehicle, recalibrations or aiming may be required.

I’ve seen shops have great success with this approach. They worked very closely with a nearby dealership, doing body work for them and others, and were there every day. The majority of the work they did fell under this dealership group as it was a multi-vehicle manufacturer dealership. The vehicle type and the fact that many of the vehicles were new worked in their favor. The main impact to them was time waiting for the dealership to finish the scans or recalibrations. The close relationship made the choice easy for this body shop and resulted in little capital expense as these services were sublet repairs.

Outside Services

Hiring a company to come in and perform procedures is another option to consider. Some companies have added this to airbag services or flash services they offer. Many made the leap and purchased OE tools to perform these operations. This allows them to service any year make and model vehicle, regardless if it’s brand new. The added advantages to this approach include:

- The vehicle stays in the shop

- OE scan tools (verify they have them)

- They chase wires

- The shop does not need equipment or personnel

- One of the appealing things about this process is the fact that somebody else does the work. The scheduling is something a shop must be incredibly disciplined on. The e-technicians (electronic technicians) are busy and routed. Last minute rescheduling can be tough. ?The costs for these services may be higher compared to other options, which could be a concern to whoever is paying for these services.

- The benefit of not needing tools and training is a plus to the shop. Be prepared as a shop will need to have the indoor space if recalibrations are needed. Level space, lighting and wall background will all be factors. Interview the company and see what tools they use and what the requirements are for them to perform the tasks.

Internet Options

There are some services that offer to do scans by connecting the vehicle to the internet. A device is connected to the OBD port and the vehicle is scanned remotely. Many times, these are OE tools doing the scans, which is great for all year vehicle make and models. Only a minor amount of training is involved for shop personnel. And, as it is a sublet, the costs and associated billing is limited for the shop.

Currently, scans are the most common service offered by these companies. Recalibrations are still being developed as these operations require people to set targets and align sensors. If there is a problem, a shop will need the personnel to resolve the issue. I’ve seen much progress from these groups in the effort to answer this need for personnel to deal with procedure issues. It’s important to keep track of the development of new programs and/or options because what may not be an option for your shop now could become one in the future. Companies are evolving at an incredible pace to meet today’s needs, so stay tuned.

Buy It

We must now talk about purchasing equipment, a step that has an incredible amount of variables. The reason for this is because no one tool does it all. The miracle tool has yet to be developed, and I doubt such a tool will ever be available. Vehicle manufacturers keep changing vehicles and their electronics. Currently, there is no uniform process or tool with the correct software to meet all needs.

In the world of electronics, the vehicle manufacturers would rather lock people out than allow access because they’re very concerned about pirating and hacking as well as function control. This forces some of the aftermarket tool companies to either wait for software changes to be released or reverse engineer their tools. This may account for the time lapse between the release of vehicle and when updates are received on new vehicles.

I will do my best to break down purchasing into two groups, OE tools and aftermarket tools.

Buying OE tools can be a costly course of action to take as buying software and updates is significant. If targets for recalibrations are also desired, the cost goes higher. The beauty is you receive updates quickly, which allows you to service new vehicles. Also, keeping the vehicle in the shop controls costs.

Training in scan tools and recalibration will be needed, which will require shops to specifically designate personnel to these processes. Repairs will also need to be handled in-house, which means chasing wires. Chasing wires can drag a technician into a quagmire of problems. After awhile, most problems become easier with experience. Again, there are more personnel required to do these procedures. This will develop into almost an entirely different classification of technician. I-CAR has already seen this and is offering a line of training to address this issue. I give a lot of credit to I-CAR for seeing and addressing this repair process for the industry quickly and correctly.

There is an advantage to buying OE tools. If you work on a lot of Toyota vehicles, for example, then purchasing the Toyota tools would be best. This would be especially advantageous if many of the vehicles are new or newer and the Toyota dealer is across town. This is where the evaluation of your needs and work becomes so critical. The type of car and logistics to dealers becomes a critical process. If you also incorporate a lot of GM vehicles, then maybe purchase their scan tool too. Each manufacturer has different software. This won’t be a one-computer-does-it-all.

Purchasing everyone’s scan tool is expensive. Only purchasing what you will get a good return on investment from is the best option.

So what about the others? This is where you need to look at your assessment. Is it newer vehicles you’re working on? If so, access to OE tools may be required. Internet-based companies could be an option. If vehicles are older, than an aftermarket system might be best.

Aftermarket tools are very flexible when it comes to addressing the issue of scanning and recalibrations. One tool may be able to do multiple manufacturer’s vehicles. They also may offer targets to be able to do recalibrations. This keeps all procedures in house and controls costs. Their will be a cost of tools and training as well as targets if desired. If your shop is in a remote location or has limited access to dealers, aftermarket tools may be even more enticing. The initial cost and also the cost of updates can be high, so measuring your ROI is important.

If problems arise, the shop will have to be prepared to resolve any codes or DTCs. Training on the use of the tools and having resources to resolve issues will need to be factored in. I also need to warn you that when doing services in-house with OE or aftermarket tools, the tools are only as good as the technician using them. Any issues you have when doing scanning or recalibrations in-house are your liability.

One issue I’ve encountered is that many times, the vehicle manufacturer adds or hides control modules. Being able to read the vehicle and see all modules may not happen until much later after the release of the vehicle to the public. This can be a problem if a large majority of vehicles serviced are brand new. Some people have told me that reverse engineering their tools to read all these control modules can be difficult. This, along with the tools not being able to access all manufacturers, requires a shop to really test the tool’s ability before purchase. As with OE and aftermarket, there may be limitations. Evaluating their help line is also a critical piece, because when you need help, you need it now.

This has been a big problem for the auto glass industry. Having the tools to recalibrate the cameras after windshield replacement or R&I has been a major hurdle for many companies. As the increase for recalibrations in repairs becomes prolific in our industry, evaluating the tool for the expansion of its abilities must also be factored.

No Single Answer

In all the testing and research I’ve done, I found there is no one answer. Each shop is different, and personnel and logistics are different. You need to assess your needs and weigh out options. There are great resources available such as I-CAR and even other shops. There are so many articles that can also help. If you need to know the differences in scans and recalibrations, look at past articles to find out the difference. For most shops, a combination of services or abilities is best. Assess what is best for you.

New Companies

I’ve seen many shops and some new companies emerge with all these changes in electronics. The companies assessed what was needed and what abilities they had in-house or needed. Some of the successes I can tell you I have seen include:

Smart Express. Smart Express of Minnesota is a successful company offering services to shops for all electronics, including chasing wires. They’re a premier company in the U.S. that understands all aspects of vehicle electronics. They offer much more services than just scan and recalibration; reprogramming and dash removal services are just a piece of what they do.

My own employer also has had success with using various services. Controlling scheduling and education to needs in pre-op are key. We use the complete spectrum depending on assessment of each of the shops in a company.

Glass companies. Glass companies such as City Wide Glass uses scan tools designed for the auto glass industry. As the need grows for these services in auto glass, think of what is needed in body shops.

Summary

You can see that companies that have adopted the right attitude toward scanning and recalibrations have successfully adjusted and are seeing revenues from these services. The point is that you need to assess what you’re doing or it make take longer for you to see a return on your investment, if you see one at all. I see many companies embracing this process and increasing sales. I am not a lawyer and can only offer best practices in repairs. So, I will repeat this word of caution: these tools are only as good as the technician using them. Whenever we start doing procedures in house or non-sublet, we take the liability into the shop. Train your people! We take on liability too with sublets but have a slightly different protection. Even if you sublet, be sure to interview the subletter and document the equipment used. Then, verify their training and certifications along with insurance coverage. Diligence is a necessity to success!