Toyota celebrated the official opening of its new North American headquarters in Plano, Texas, with a July 6 gala attended by hundreds of dignitaries, partners and community leaders.

“The opening of our new headquarters in Plano is an extraordinary next step in Toyota’s 60-year journey in the United States,” said Jim Lentz, CEO of Toyota in North America. “With team members from four different companies together in one campus location, we believe this will inspire greater collaboration, innovation and faster decision-making as we turn to and lead the future of mobility, all with an eye on our customers.”

Lentz also thanked President Trump, who sent a written, signed statement congratulating Toyota on the grand opening.

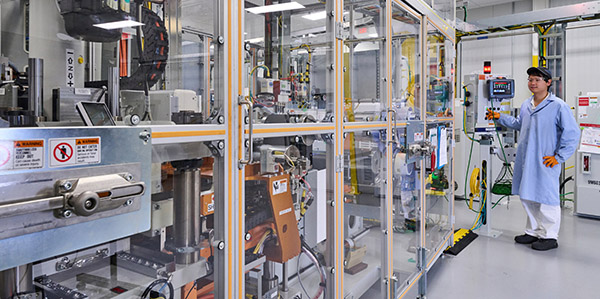

Three years ago, the automaker announced its “One Toyota” initiative to create more unified operations in North America. Part of the strategy is to gather the company’s quality engineering, sales, marketing, financial services and corporate functions in one location, Toyota said.

Since then, the company has invested about $1 billion on the project to build its new corporate campus on 100 acres in Plano and move thousands of team members and their families from California, Kentucky and beyond to North Texas.

With construction nearly complete, Toyota employees began moving into the building in late spring. The move-in process will continue through December, Toyota noted.

Toyota will have jobs for up to 4,000 Toyota team members in Plano, according to the company.

In addition to the employees who chose to relocate, Toyota previously announced that it would hire more than 1,000 new team members. Toyota said it already has filled more than 75 percent of its open positions.

Focus on Sustainability

Among the seven buildings on the campus is a large central courtyard that serves as the literal and symbolic heart of all social and business functions – including dining, fitness and conferencing facilities.

Toyota said it aims to achieve LEED Platinum certification from the U.S. Green Building Council by offering:

- Exterior landscaping reflects the native habitat, with drought-resistant plants

- An 8.79-megawatt array of more than 20,000 solar panels

- A commitment to use only renewable energy, purchasing all electricity not generated by the solar panels from wind generated by Texas farms

- A rainwater harvesting system, up to 400,000 gallons, to use in irrigation

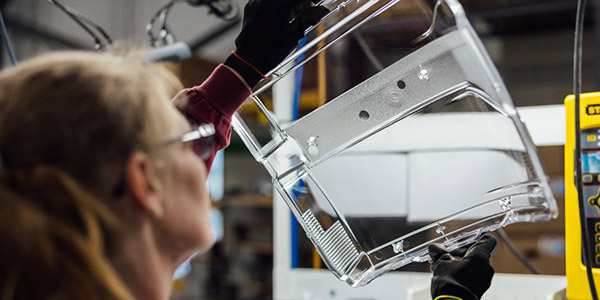

“Our new campus has fun, unexpected, and even playful features that reflect our commitment to be a world-class leader in innovation with state-of-the-art facilities and cutting-edge technologies,” said Doug Beebe, general manager of real estate and facilities for Toyota Motor North America. “It also is a great example of Toyota’s commitment to environmental sustainability. Because of its architecture, its central location and the lively, flourishing community around it, we can share ideas and make great things happen here. We are proud of this campus because we have designed it to allow team members to get out of their office space and come together. And that’s really the spirit of One Toyota.”