As more hybrid electric vehicles (HEVs) and battery electric vehicles (BEVs) roll into shops needing welding repair, I-CAR’s technical subject matter experts are often asked to provide guidance about specific safety precautions.

Precautions

When welding on a hybrid vehicle or electric vehicle, you should follow the same precautions with the 12-volt system as when welding on a conventional vehicle. In addition, there are precautions to take with high-voltage batteries. Remember to disconnect both the 12-volt battery and the high-voltage battery service disconnect. (Note: Always disable the high-voltage battery according to the vehicle maker’s repair information and follow all safety precautions).

Keep in mind that there is typically more than one method available for disabling the high-voltage system. The preferred disabling method for repair technicians would be to remove the hybrid battery service disconnect following the vehicle maker’s service requirements. Also, one way of ensuring safety is to keep any removed fuses, relays or service plugs in a secure, remote location to prevent others from reinstalling them without your knowledge.

It’s All in the Details

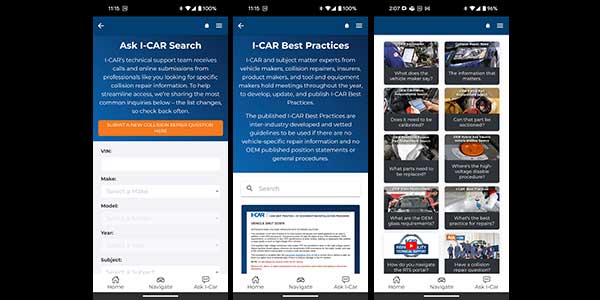

Not only are there a variety of disabling methods but the procedures are often difficult to locate. However, help is only a click away with I-CAR’s complimentary online resource, OEM Hybrid and Electric Vehicle Disable Search. This interactive tool was created by I-CAR’s Repairability Technical Support (RTS) team and represents countless hours of research on hybrid and electric vehicles.

Properly disabling a hybrid vehicle is also critical for personal safety. The search tool will help you identify where parts of the hybrid system are located; instructions for finding the disabling procedures; whether a scan tool or a high-voltage, digital voltage-ohm meter (DVOM) is required to disable the high-voltage system; and best practices to help ensure a complete, safe and quality repair.

A Click Away

The real-time resource is the only such feature of its kind designed exclusively for the needs of the collision repair inter-industry. Here’s a quick “how to conduct a search” overview.

To search for a vehicle, click the blue OEM Hybrid And Electric Vehicle Disable Search button on the left-hand side of the screen. Select the year, make and model from the dropdown menus, then click search. A search results page will load. Select the vehicle from the list of search results by clicking on the blue text.

The make, model and year of the vehicle, along with a small picture, are displayed near the top of the screen. There are also links to OEM Repair Information, the Hybrid And Electric Vehicle Article Hotspot, and Emergency Response Guides (OEM-specific).

There are step-by-step instructions on how to access the high-voltage battery disabling procedure on the OEM website. The instructions can change from vehicle to vehicle depending on the year or how the OEM created the service or body repair manual. Access to the disabling procedures may require a subscription to the OEM service information.

On the right-hand side of the page, next to the step-by-step, is a chart that identifies if a scan tool or HV DVOM is required in the disabling of the high-voltage battery, according to the OEM procedure. These are identified using an “X” under yes, no or not identified. Not identified means that the OEM does not specify in the repair information if a scan tool or HV DVOM is required to disable the high-voltage battery.

The next thing you’ll see is a battery layout graphic that gives an approximate representation of where the high-voltage battery, 12-volt battery, mid-voltage battery and high-voltage disconnect are located on a specific vehicle. Each component is color-coded according to the key at the bottom of the image.

Hybrid Welding Best Practices and Refinish Precautions offer important information for vehicle’s repair process. These precautions and best practices help to ensure the battery and other high-voltage components are not damaged. The welding best practices and refinish precautions are typically quoted from the OEM. In the event these are not provided by the OEM, I-CAR best practices/precautions are shown. Here you may also notice paint booth temperature specifications and steps to take before welding on an HEV or EV.

It’s important to note that this matrix does not currently contain all production vehicles sold in the U.S. Refer back to this page frequently for the most up-to-date information. The OEM-specific repair information was identified from the vehicle makers’ repair information, and contents are based on the information available from them. Updates and additions are posted as they become available. To ensure that the most recent information is used, always refer to the vehicle maker’s technical information when disabling and working on HEVs and EVs.

Welding Training and Certification

Need welding training or a refresh? I-CAR’s Welding Training & Certification comprises a set of three in-shop courses that enable a technician to understand, practice and be tested on proper welding techniques relative to course objectives and skill level expectations. Each course begins with a qualified I-CAR welding instructor providing an assessment of a shop’s welding capability and readiness (infrastructure, welders and related equipment) and is followed by instruction, coaching and training technicians. Once the training portion is complete, a certification test is given to ensure course objectives and skill expectations are met. This helps I-CAR fulfill its vision to the industry: that every person in the collision repair industry has the information, knowledge and skills required to perform complete, safe and quality repairs for the ultimate benefit of the consumer.

I-CAR’s Welding Recertification is designed for the technician who has maintained welding proficiency through regular application of his or her knowledge and skills in the shop environment while performing vehicle repairs. A certified welding technician should have a lot of confidence in his or her ability to complete the required welds and other tasks with no assistance or training. And did you know recertification is valid for three years? Note: A welding recertification course cannot be scheduled as a standalone event. Another instructor-led course, such as a Hands-On Skills Development (HOSD) course or a full welding certification course, must be scheduled for the same day.

Related I-CAR Courses

Now is an ideal time to assess your shop’s training needs, both for the balance of 2022 as well as training plans for 2023. Visit i-car.com to check out course objectives to better understand how you can support your organization’s ability to remain current to changing industry repair needs.