If we think we have it bad … tough competition,

controls by others outside the industry and liability exposure,

just look at the glass industry and its world.

Afterward, be happy you’re in the collision

repair business!

Unfortunately for us, the glass industry is

going through what our industry is apparently heading toward.

Consolidation will ultimately affect pricing of our services,

decrease our repair turn around times and increase competition

of convenience.

To think … some time long, long ago,

the retail list price for glass was really the retail list price

for glass.

If you’re thinking about doing your own glass

work and you’ve weighed all the factors, I have two statements

for you. If you answer "true" to both, then it probably

is a necessary strategy for your future:

- Your volume of glass work internally and/or externally makes

this venture profitable. - No one in your area has the proper skills, or they don’t provide

you quality service.

Business Decisions

Taking on glass installation would be no different than any other

business venture. You need to have a reliable and competitive

wholesale source, a staff with the proper skills and certifications,

up-to-date tools and materials, and the time to properly manage

the business. Without all of these in place, you surely wouldn’t

consider entering into this arena, would you?

Keep in mind, even if you elect not to enter the glass-installation

business, you still need to understand the procedures necessary

for proper installations and the liability you continue to incur.

Whether you actually do the work internally or sublet it to another

company, in most cases, you’re still liable. Unless the glass

installation is direct billed to and the contract is directed

by the insurer, the vehicle owner has a contract with you, not

with whom you elected to do the installation. For this reason,

it’s important that you’re very well informed – even when contracting

someone to perform the glass work for you.

To do this, let’s examine some areas of consideration.

The Source

Your first area of consideration is your glass source. It’ll be

difficult to achieve discounts on glass to a competitive level

with normal, small purchase volumes. In fact, most collision repair

facilities have found they can establish contracts with outside

vendors to do the complete job, including the cost of the glass,

for what they can buy the glass for. Their profit, then, is realized

through an acceptable mark up on the glass plus the installation

labor and materials.

This doesn’t solve the problem if the source is unreliable or

you just don’t receive the service you need. In these cases, you

may elect to re-examine your sources again. Send a bid letter

explaining your needs to all vendors, and ask them to bid on your

account. Include your last year’s annual purchases in glass replacement

and other glass needs, plus set a contract time frame, such as

one year. This gives vendors an idea of your anticipated volume

and some security in their investment for your account.

Glass Standards

The role of glass today is not just to stop bugs from getting

into our eyes. Glass plays an important structural role as well,

and this role is predicted to increase in the future.

To help ensure safe installations – along with safety in general

– The National Highway Transportation Safety Administration (NHTSA)

develops Motor Vehicle Safety Standards (MVSS) for vehicles sold

in or imported to the United States. The windshield and its installation

method (original manufacturing) must be able to pass two performance

standards: MVSS 212 and MVSS 216. These two tests, even though

they’re designed for vehicle manufacturers, have also become the

standard for aftermarket repairs since we are – by default – contracted

to restore the vehicle to pre-accident condition.

- MVSS 212 – Commonly called the windshield retention test,

MVSS 212 requires the windshield to keep the front-seat occupants

from exiting through the windshield in a frontal collision. The

test is performed at 30 mph into a fixed barrier. The windshield

must maintain at least a 75 percent perimeter after unrestrained

occupants hit the windshield. - MVSS 216 – Commonly called the roll-over test, MVSS 216 requires

the windshield and A-pillar area to withstand 1.5 times the weight

of the vehicle directed downward at the front of the roof without

crushing more than 5 inches during the two-minute test. Since

roll-overs vary greatly, this test is performed with a crushing

panel applied to the front of the roof. The vehicle must be secured

so the suspension isn’t a factor, and all other windows are closed,

such as sunroofs and doors. - MVSS 208 – This is another standard that indirectly affects

the replacement of windshields. Although this standard is designed

for passenger air-bag deployment, in the specification it acknowledges

that the passenger air bags designed to rebound off the windshield

for proper positioning will do so with a force of 300 pounds per

square inch. Therefore, for proper placement of the passenger

air bags, the windshield must be able to withstand this force

without being pushed out.

The preparation, method of installation, adhesives used, temperature

and humidity during installation, and the proper cure time all

directly affect whether the installation will meet the above three

safety standards. For these reasons, it’s very important to distinguish

between glass installations from the past and what’s required

today. Even auto manufacturers have specific requirements that

differ from each other.

The Tools

Today, specialty tools have become commonplace for glass installations.

Electric or pneumatic power cutting tools, inflatable bags and

suction cups have replaced the cold knife and piano wire in many

applications. These methods allow for the removal of some very

difficult glass designs, but they require training and practice

– otherwise, the glass and interior trim may be damaged.

Even with conventional tools, training and understanding are needed.

One common mistake made when using the common cold knife is not

properly sharpening the blades before using them. It’s also important

that the blade be positioned properly when pulling it through

the urethane. The cutting blade section should rest as close and

parallel to the glass surface as possible when cutting. When this

isn’t accomplished, the blade or glass breaks and pulls through

the urethane like you’re pulling against a team of horses.

Materials and Preparation

Before windshield retention standards were implemented, most windshields

were installed with butyl tape or set in a rubber gasket. The

primary purpose of these methods was to keep the windshield from

leaking and to set it in something flexible so when the vehicle

body flexed, the windshield didn’t crack.

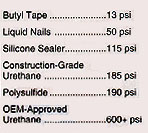

Butyl tape supplies a bonding strength of approximately 13 psi.

This, of course, is far from the passenger air-bag deployment

pressure placed on the windshield in the MVSS 208. However, it’s

possible for a butyl tape installation to pass the MVSS 212.

Since the Motor Vehicle Safety Standards don’t provide a minimum

strength for adhesives (except by indirect means), auto manufacturers

have their own standards or OEM specifications. The OEM-approved

urethane adhesives today supply more than 600 psi of tensile strength,

and there hasn’t been any adverse effect identified with using

an adhesive that’s too strong, just too weak.

Unfortunately, there are other factors that affect the installation

besides the adhesive specifications. These include surface preparation,

curing time, temperature, humidity and the size of the bonding

surface. As it’s been stated, "A chain is only as strong

as its weakest link." Any one of these can easily cause the

installation to fail.

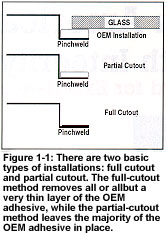

Installation Method

There are two basic types of installations: full cutout and partial

cutout (Figure 1-1). Note: Auto manufacturers may have specific

recommendations for the type of installation they approve, and

it’s important to follow these recommendations as outlined.

The full-cutout method removes all or all but a very thin layer

of the OEM adhesive, while the partial-cutout method leaves the

majority of the OEM adhesive in place.

Generally, auto manufacturers will have guidelines regarding whether

a partial-cutout method is approved for their vehicles but, in

many cases, the condition of the pinchweld area will dictate a

full-cutout method, even though the manufacturer allows otherwise.

If the pinchweld area is damaged, it’s likely the adhesive will

be removed completely in the repair area. This then requires a

full-cutout method.

Using the partial-cutout method (if approved) is best advised

immediately after cutting out the old windshield. This ensures

a very clean surface for bonding. If the windshield isn’t installed

immediately, it’s best to cut another layer to expose a freshly

cut urethane bonding area or perform a full-cutout method.

A special note should also be made in regard to repair work in

these areas. All metal work areas where an adhesive will be applied

should be "metal finished." In these areas, no plastic

filler should be used since its adhesion characteristics are lower

than urethane adhesive. Also during refinishing, pinchwelds should

be primed with the appropriate epoxy or self-etching primer but

generally not topcoated or cleared. Again, the paint system could

be considered the weakest link.

Surface Preparation

Proper preparation before installation is critical. The glass

surface where the adhesive is to be applied must be properly cleaned

– or the adhesive won’t be effective. This includes using a complete

system designed by the adhesive manufacturer. We’ve finally learned

not to intermix systems with our refinishing products, and it’s

extremely important to stay within a system when preparing glass

for installation too.

The cleaning begins with a glass cleaner designed for the system,

which won’t leave a film or residue. Even a finger print in the

adhesive area can cause the adhesive to fail during testing, so

this step must not be overlooked.

Some systems will require a special primer be applied to the glass.

This primer may or may not be the same primer recommended on the

pinchweld area. In some applications, an additional ultraviolet

(UV) protection coating may be called for if the glass doesn’t

already have it applied.

In the pinchweld area, special primers are designed for any bare

areas before application of the adhesives. Any loose original

adhesive must be removed, and the original urethane must be clean.

Since urethane can be porous, it’s not normally recommended to

use a solvent-type cleaner. Water can be used, but the area must

be dry before installation. Again, the adhesive manufacturer will

have specific recommendations for these conditions.

Curing Times

You’ve probably heard phrases such as "ultimate curing time"

and "safe drive-away time" when discussing adhesives.

But be very careful when considering what these phrases actually

mean; they may not be referring to what you think.

The ultimate cure time is simply the time it takes the adhesive

to fully cure. The safe drive-away time refers to the time it

takes to reach or exceed MVSS 212. Wait a minute, what about the

other two standards? Because these phrases are often used too

loosely, they may imply something you don’t mean. Make sure to

ask specific questions.

Also, the ultimate cure time and the safe drive-away time are

sometimes ignored to facilitate speedy delivery of the vehicle

back to the owner. Some adhesive advertising may even loosely

use these terms for a competitive advantage.

Keep in mind, if you install (or have installed) a windshield

and the adhesive isn’t totally cured or doesn’t meet all three

safety standards and you deliver the vehicle to the customer,

you’ve exposed yourself and the company to an extreme liability

situation.

If the customer (or employees, for that matter) has an accident

in the vehicle and the adhesive hasn’t properly cured to exceed

these standards, this installation could cause personal injury

or death. If this happens – whether you personally installed the

windshield, had an employee do it or had another company do it

– you are liable. You may be asking yourself, "What’s the

chance of the vehicle getting into another collision on the way

home?" It’s not worth the risk, believe me.

Temperature and Humidity

Different adhesives are designed for different weather conditions.

Some may be single component while others may be two component.

They all have a specific range of use for which they were designed,

so it’s important to know the specifics of all products in the

system and make sure they’re used accordingly. It’s also recommended

to allow adhesives to dry naturally unless specifically designated

otherwise. Heating units normally aren’t advised for most adhesives.

Not only is temperature a factor, but so is humidity. Urethanes

used today cure with the assistance of moisture in the air. So

even if the room temperature is above 70 degrees F, it’s possible

to have very low humidity, which will hinder proper curing times.

For situations such as this, it may be necessary to use running

water to increase the moisture content of the air.

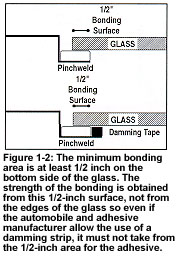

Proper Bonding

Even after proper surface preparation, the adhesive still must

have a large enough area to bond to the glass properly. The minimum

bonding area is at least 1/2 inch on the bottom side of the glass

(Figure 1-2). The strength of the bonding is obtained from this

1/2-inch surface, not from the edges of the glass.

Sometimes, a damming strip or tape is used as a backstop for the

urethane adhesive. This damming strip is placed down on the edge

of the pinchweld. Note: Using these damming strips may not be

possible on very narrow pinchweld areas. Even if the automobile

and adhesive manufacturer allow the use of a damming strip, it

must not take from the 1/2-inch area for the adhesive (Figure

1-2).

It’s also important to understand that these damming tapes or

strips don’t provide sufficient bonding for an immediate "drive

away." They assist in holding the glass in place during curing,

but this doesn’t meet all safety standards.

Documentation

Having a method of documenting or receiving documentation from

your vendor about these installation factors is also extremely

important. The following information should always be documented

when the installation takes place:

- Date and time of installation.

- Vehicle information (year, make, VIN number).

- Owner information (name, address, repair order).

- Installer information (name, company).

- Location of installation (where, inside or outside, temperature,

relative humidity). - Part information (name, part number/NAGS number, clips and

moldings replaced). - Adhesive (brand, part number, batch number, primer used).

- Installation method (full or partial, dam type used).

- Release (date and time).

- Additional notes.

Without this documentation, you have no proof of the method or

products used if there’s ever a question regarding proper installation.

Many pre-made forms are available to document this, but what’s

important is that you do it consistently. Whether you do the glass

work internally or sublet it, you need documentation for every

job.

Managing the Business

The collision repair portion of your business requires proper

management to perform and be successful. And, if you elect to

venture into the glass business, you need to have the management

skills and knowledge for this industry too. There are national,

state and local associations for the glass industry to help you

do this, just as there are for the collision industry. I’ve had

the opportunity to speak with these glass-specific groups in the

past, and they offer a valuable service to their membership.

The key here is to not take for granted the skills and investment

required to perform this service. And don’t forget the liability

issues involved, which can be extreme; some of the awards given

by the courts in the last several years have been in the millions

of dollars.

If you thought auto glass installation was easy and that anyone

could do it, think again. The knowledge and skills required today

for proper glass installation equal the knowledge and skills required

to properly repair collision damage on today’s vehicles. And,

as with collision repair, glass installation isn’t for everyone.

The question is: Is it for you?

Contributing editor Tony Passwater is a long-time industry

educator and consultant who’s been a collision repair facility

owner, vocational educator and I-CAR international instructor.

He’s taught seminars across the United States, Korea and China

and is currently an industry consultant. He can be contacted at

(317) 290-0611 or [email protected].

|

Training and Certification Proper training and certification are extremely critical today when it comes to proper glass installation. The days of just "short cutting it" and using a bead of urethane are gone!

Major suppliers generally have their own internal training and

National training organizations dedicated to the auto glass industry

For certification, the National Glass Association (NGA) offers

If you wish to become informed but still want to sublet your glass |