Adhesive bonding has been around for a long time. It’s a very effective way to bond vehicles together…when done correctly.

Adhesive bonding offers tremendous advantages to both vehicle manufacturers and repair shops. Recent events, however, have made shops a little gun shy about using this repair process. This should not be. Follow the vehicle manufacturer guidelines and there should be no problems. However, if you perform a random repair assuming it will work versus following the OE requirements, it could blow up in your face. Always read the directions! Many automakers require a mechanical fastener, be it a rivet or weld, to produce the strength needed. Adhesive-only repairs should be done only when there is a written procedure from the vehicle manufacturer for that year, make and model.

The advantages to using adhesives during manufacturing include:

- Adding strength to a vehicle

- Reducing weight

- Reducing noise, vibration and harshness (NVH)

- Adding to corrosion protection, extending the vehicle’s end of life (ELV)

A Nuisance?

What’s not to like about this stuff? I see many shops omitting adhesives from repairs because they see it as a slow-down or nuisance. This attitude primarily comes from lack of knowledge of the product or lack of training. Some vehicle manufacturers have changes in repair procedures or number of welds and do allow omitting adhesives during repairs. However, a number of them are adamant about their use. The idea of re-engineering their vehicle or changing the corrosion protection is not acceptable to the automakers. Establishing the correct procedure and being sure technicians are trained to use these products correctly will benefit any repair facility. The use of adhesives increases the quality of repair tremendously for all the reasons listed above and makes the repairs the shop has completed last longer.

Flexibility

Adhesive bonding can be applied to many types of repairs. You can bond dissimilar metals or any other materials. There is no damaging of temperature- sensitive metals due to heat. It can be done quickly or slowly depending on the product used and the work time. Adhesives cure quickly, and they can function in extreme temperatures. All these variables make adhesives a great choice for assembly by the automaker and the shop.

There are structural adhesives and non-structural. The way vehicle manufacturers use adhesives on vehicles today can be broken down into three categories:

- Adhesive-only bonding

- Rivet bonding – rivets and adhesive

- Weld bonding – STRSW welds, MIG/MAG welds and adhesive

Training

In recent years, I’ve seen a pattern develop in many shops. I’m going to be a little blunt here and I may offend many shops, but from what I’ve seen out there, shops have decided to limit technician training. I understand training can be expensive to shops, but my answer to that is, “Quality work is priceless.” Here are a few scenarios I see:

- No training. The shop decides to not send technicians to any training.

- One-person training. One person taking training to meet training requirements but does not train other shop personnel.

- Role rep-only training to meet requirements. The outcome is the same as one-person training as other techs do not receive training.

- Ignore training. Ignore training and do it their own way.

- Train ‘em all. All employees get training on products and processes.

Your shop falls into one of these categories. So here’s the offensive part: If you’re skipping training or not training technicians on what they need to do their job correctly, be it any procedure or product use, you’re asking for problems. The excuse that it’s too expensive is not a good argument as many vendors will train you on using their products for free. For those of you who think I-CAR training is a waste or too expensive, you haven’t attended a class lately. I-CAR has stepped up its training, including hands-on training. If you feel you know all you need to know, I can’t help you. The reason I say this is everything is changing. Keeping up is difficult, but it must be done. Shops need to teach all technicians about the use of certain products to reduce or prevent comebacks.

Breaking It Down

Adhesive-only bonding is used by all manufacturers on almost every vehicle. Where do they use it? The windshield, for example, is adhesively bonded to the vehicle. Adhesively bonding a windshield requires very specific training as there is a great deal of liability. Bonding glass to metal is a much more complex process than you see when a glass guy installs your glass. Use of products and preparation of surfaces is critical knowledge a technician must have. As the windshield is structural in all vehicles, the process must not be taken lightly. Windshield urethane is much different than most adhesives used in collision repair. It is a one-part moisture cure product. The strength ratings of these products as well as flexibility is impressive, and they require no mechanical fasteners to increase strength. The bond-line thickness allows for stronger strengths than thinner bond-line counterparts. This is why the windshield urethane is also used in bonding roofs that were laser brazed at the assembly plant.

Adhesives used to panel-bond vehicles are slightly different as these are usually two-part products that are also much thinner, forming a thin bond line. This thin bond line creates some issues in adhesive products, generally speaking. Although tensile and lap shear strengths are great, peel strength suffers from the thinness and brittleness of the product. This is evident when doing a panel removal. You work with the panel until a point of “pop,” and the rest of the panel releases suddenly. This is why many vehicle manufacturers use a mechanical fastener system to prevent peeling in collisions. Among other reasons, numerous vehicle manufacturers’ instructions require that their adhesives not be used without a fastener. Adhesive-only panel bonding is limited at this time to very few operations.

Structural adhesives have seen some increase in use in newer vehicles. Although mechanical fasteners may not be required, they may be adding strength to an engineering change that may not be obvious. Some of this is based on the fact that welding would heat-damage steel and corrosion protection, where structural adhesives would not.

Whether you’re using panel bond adhesive or urethane adhesive, knowing how to prepare the surface is critical. Urethane adhesives require a primer to bare metal and treated surfaces, whereas panel bond adhesives may need to be applied to bare metal or treated metal. Different manufacturers of these products have different standard operating procedures, which is why vendor training is so important as a technician may use procedures from previous products used at school or a previous employer. This can really make for a bad day at work.

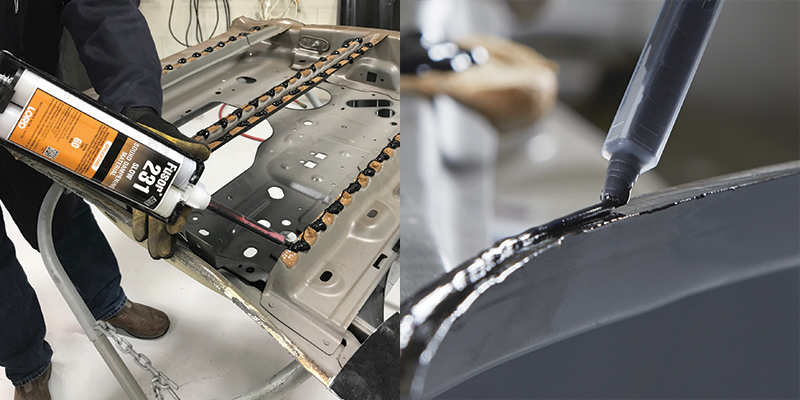

Many adhesives have a glass bead technology that somewhat controls the thickness of the product as clamps are applied to press panels together. Other products may use shims to do the same. Be careful of how much product is used. Follow the instructions! Too little product can be just as bad as too much. Clamping pressure is also a factor in appearance and function. Surface preparation guidelines are also non-negotiable per the procedures. Never assume anything. Again…follow directions!

While adhesive-only bonding has its application in certain places, be sure to only use it where instructed. Assuming it should work is a dangerous thought process.

Rivet Bonding

The new F-Series truck really brought rivet bonding to the forefront. Before Ford’s big leap, many weren’t sure how strong of a repair this procedure made or really how the heck to do it. Once they learned, however, they figured out that the process was very straightforward. Although used in steel manufacturing, it was the aluminum procedures that put a spotlight on rivet bonding.

The adhesives still maintain all the properties mentioned before, but the rivets add strength and reduce the peeling of metals from each other, adding a pulse to bleed energy throughout the vehicle in a collision. It’s very similar to spot welding without using heat to join metals.

Rivets alone are susceptible to failing as the bonding of the two materials may allow for movement over time from repeated stress. Rivets and welds, for that matter, may break loose. The combination of rivets and adhesive corrects the weakness of either system being used alone, which gives manufacturers a no-heat bond that would damage many steels or other metals. This also gives shops a way to easily duplicate factory build procedures, keeping with the engineering specs. The combination results in an incredibly strong and long-lasting bond that can withstand the repeated stresses of driving or forces in a crash.

There are some things to consider when using self-piercing rivets (SPRs) or blind rivets and MIG/MAG welds and adhesives:

Type of metal. Steel and aluminum may have similar procedures. but there are some with specifics to metal preparation.

Type of rivet. Whether SPR or blind, be sure to use the right rivet for strength and appearance. A weld may be a better choice than a rivet on some aluminum applications.

Dissimilar metals. Be aware of their use and know that the bond line must be done correctly.

The corrosion protection properties must be noted as well. Adhesives used in all processes offer incredible corrosion protection. As all metals may succumb to some form of this aggravating issue, it’s important that we apply the best process available. Panel bond adhesives definitely qualify as one of the best corrosion protection options we have. As it is applied between metals and dissimilar metals, it prevents galvanic

corrosion also.

Weld Bonding

As with rivets, adhesives can be used with welding panels together also. Squeeze-type resistance spot welding (STRSW) can weld through many adhesives to form a strong, long-lasting bond. The machine you use must be capable of weld bonding and have pulse energy in order to make a correct spot weld. If your shop is set up with the right equipment, then the new I-CAR hands-on STRSW course would be for you. To complete the welds correctly, training on your welder and knowledge of procedures is a must. Many technicians struggle with these STRSW machines as they have not been trained. There’s a big difference between showing someone and training someone. Proper metal prep and preparation is absolutely critical to making successful repairs. Training for manually setting the machine is also required by one particular vehicle maker.

MIG/MAG welding is also used with adhesives. Although you can’t weld through the adhesive with a gas metal arc welder (GMAW) (which is commonly referred to as wire feed welding), specific procedures are available from vehicle manufacturers on how to complete the process. Welding through the adhesive is not done during this procedure. Proper spacing of the adhesive from the weld zone as well as the correct-power welder (220/240) is a critical step. A weak welder will take too long to make the weld, burning the adhesive.

Summary

Weld bonding and the use of adhesives in any of the processes mentioned has made a significant impact in the longevity of today’s vehicles. As spot welds are under constant stress from driving and heat and cold expansion, they may fatigue and weaken. Or, corrosion may start as the metal becomes exposed. Adhesives in weld bonding dramatically reduce the stress and fatigue on spot welds, offering longer vehicle life. This is an important note for shops as we want our repairs to last. Weld bonding gives a shop that advantage, just as it does the vehicle manufacturer. The corrosion protection and fatigue reduction as well as NVH properties are a win for any repair shop.

Note: Seam sealer welding or sealer welding is becoming more popular as numerous seam sealers can be welded with STRSW machines. Please be aware of confusing the process. Seam sealers must not be used in place of adhesives. This would be considered a serious compromise to the vehicle. Sealer welding should only be used where no adhesive was used by the vehicle manufacturer. BSB