Automotive repair has changed drastically in a very short time. Changes in metals and plastics as well as different strengths of steels in vehicle design have required shops to buy new equipment to repair the amalgam of construction materials being used in today’s automobiles.

You, as a shop manager or owner, bought the equipment because you needed to keep aligned with what the vehicle manufacturer was requiring to be done to repair the vehicles correctly. It was a necessary purchase to keep your shop in line with the vehicles your customers were bringing to your door, trusting that you were the expert with the knowledge and tools to get the job done.

It wasn’t about building a profit center in your shop but was a necessity to do business as vehicles evolved. There wasn’t much thought about space in the shop except if you were repairing aluminum, but when you weren’t using that dedicated aluminum repair space, you could work on non-aluminum vehicles without wasting space or needing to add space in your shop. All this equipment and technician training was needed to grow your shop to be able to repair vehicles correctly.

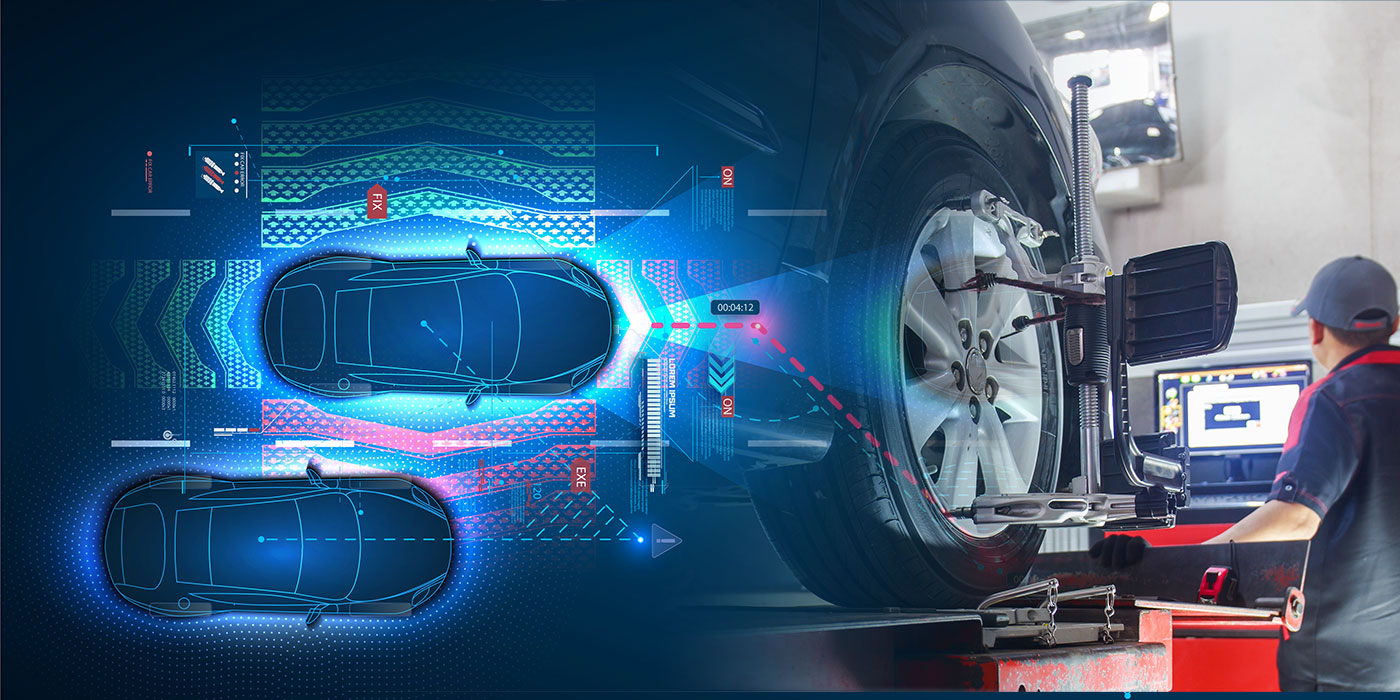

Today, electronics have changed the landscape of automotive repair tremendously — not just the purchase of equipment but also the amount of space required to do calibrations, surround view camera calibrations and blind spot, just to name a few. As these services become more necessary on all vehicles, the combination of equipment and space in a shop adds a whole different angle on growing it to compete in today’s and tomorrow’s vehicle repairs.

Calibration Equipment

At this year’s SEMA Show, calibration equipment was everywhere. Everyone had their angle or twist on how their equipment worked to make your shop money. How do you know what equipment to buy, or is subletting the work still your best option? It’s like buying a car. Here is the base model and price, but if you want more options, here is the price. And next year’s model will make this model obsolete.

If your shop is at capacity as far as production space, finding another large work area to do calibrations is a major concern.

It’s an investment to buy-in and make calibrations a profit center in your shop. But when will a return on investment (ROI) be seen? I am not a shop owner and am not giving any advice or a complete picture of all that a shop must look at to add a profit center. I am merely offering some observations for owners looking to add these particular services. Owners know their shops and their needs and must make their own decisions if adding these services at this time is a correct plan of action.

Profit Center

After walking through the SEMA Show and seeing all the equipment, it really started coming together in my thoughts. If you wish to make a profit center in your shop, you’ll need to examine a few things closely to begin your journey. Once you look at these main points, you can break them down in subsections for your needs and reporting:

- How much many can you spend? (ROI)

- How much space do you have?

- Do you have enough work coming through the door?

- Do you have a technician ready?

- Who is going to diagnose the problems if calibrations fail or programming is needed?

- Do you have technical support when things go wrong?

Money and Space

“How much capital will it take to buy equipment?” is a tricky question. At SEMA, there were so many choices. Hunter Engineering did an awesome demonstration of its new system that uses lasers to tell you where to set your targets. Keep in mind that, in addition to these target systems, you still need scan tools and software to access the vehicle and the modules to scan, program and calibrate. Some of the systems included the scan tool and software for the vehicle in the price, but some did not. Autel showcased its equipment for shop solutions, as did Opus IVS and a plethora of others.

It’s interesting to note there has yet to be a solution invented for all vehicles. The calibration equipment manufacturers were all great at telling you what their tools can do, but you have to dig and research to find out what they can’t do. I suppose it will never be perfect, as the repair needs between OE software and gateways keep changing with each new year, keeping the aftermarket a step behind and shops always renewing OE subscriptions for the OE scan tools for new vehicles.

A shop can learn to do calibrations, but you also need to be able to diagnose problems.

As the focus turns to vehicle alignment before the calibration process, I’m amazed at how big the equipment and stands are getting and the space they’ll consume to do the job. Don’t get me wrong: The space was always needed to place targets correctly. The point is that the equipment and stands or target systems are also adding to the space requirement with the way they move to align to the vehicle or, in some cases, how they fit in the shop.

Another point on the space is: How much room do you have in your shop for the equipment and space needed to do calibrations? If your shop is at capacity as far as production space, finding another large work area to do calibrations is a major concern, especially when you start looking at calibrating surround-view systems. So the first question is: Do you have the space? What will you sacrifice to make this space, and how much will that add to the cost of the equipment?

How much do you have to spend? You can buy equipment at a wide variety of price ranges. With a stand to hold targets and the targets themselves, you could spend $12,000 to $80,000. Yes, I know there are cheaper models and more expensive models, but I’m merely giving a range of costs to give you the ability to complete calibrations on just 70% of the vehicles on the road. As I said, not all equipment manufacturers have all the coverage yet.

Now, let’s take a look at your outside services expenditure. How much money did you spend last year on calibration services? You can assume that outside cost will go away, but it actually will not, as you’ll learn that there will be vehicles you do not have coverage for — and sometimes the diagnostic solution will elude you.

The similarity between looking at equipment, space, technician time and training to bring calibrations in-house parallels doing alignments in-house. If you’ve already brought alignments in-house, there are systems to add to the alignment equipment to complete some calibrations. All the angles must be weighed, as this is a major commitment for your shop that you as an owner will need to weigh in on, considering that next year you’ll have more choices and gizmos. You also need to look at software subscription fees to access vehicles in order to complete calibrations. You may choose one aftermarket system that has major vehicle coverage, or you may need individual software subscriptions and equipment for your shop’s OEM certifications.

Training

Now look at the charges per vehicle and the number of calibrations increasing every day. Do you have the need to add to your services? When do you see getting your ROI for the space and equipment? Before you do that, you also need to add in training a technician to operate the equipment. Do you have your lead tech, or do you need to hire someone to fill this role? This cost can be an evolving one as technicians leave and you have to start the training process all over.

Make no mistake: It takes time to become efficient at calibrations on all the vehicles we must service. It takes even longer to learn to diagnose vehicle electronics issues. Time will be needed to build experience and efficiency. This can be a point of frustration, as many assume you can just add equipment and go. Experience matters when a vehicle has been in a crash or has been on the road for a few years. It’s easier to fix a vehicle that has never been damaged or if you’re a dealer and only work on one vehicle manufacturer. This experience will lead you to some other tools you’ll need, such as a good battery maintainer, de-pinning tools, digital volt-ohmeter (DVOM), etc. And, if you’re going to do electric vehicles (EV), even more tools will be needed along with EV training. That’s a whole other rabbit hole to go down.

When Things Go Wrong

We all know Murphy’s Law: If it can go wrong, it will — and at the worst time. We’ve all been there and will be again. The variables to repairing vehicle electronics after a crash can be mind-boggling to many technicians. Crushed or cut wires to shock damage to connectors and just simple wear and tear can consume a lot of time for a technician trying to find a fault in the system.

A shop can learn to do calibrations, but you also need to be able to diagnose problems. This is why I said earlier that the outside service bill will not go away. I don’t feel the companies offering mobile service will go away from your shop either. You may choose to do calibrations, and when they go great, everything is good in your shop. However, when calibrations fail, that’s when you’ll need some experience to come in or send the vehicle to somebody if you do not have a technician with the necessary experience. “Nobody knows everything” is a common phrase, as each vehicle manufacturer says something different as far as what must be done when replacing collision-damaged components. Sometimes you’ll need the vehicle IT department to come in and see what needs to be programmed. You can buy all the equipment you need, but you’ll still need a technician to do the calibrations and someone to diagnose for solutions when it does not work.

Support

To me, support is one of the repair industry’s biggest needs. Everyone makes equipment, but I always hear complaints about support when something is not working and there is a lack of solutions. It goes hand in hand with the aforementioned diagnostic technician. Does the equipment manufacturer offer support when you need it? Does it take minutes, hours or days to get back to you or to resolve an issue? These issues are why the dealer or mobile service comes in to fix the issue that’s stopping your vehicle from being delivered. That delay and the cost for your shop can be expensive. I understand the argument from equipment manufacturers that the tech support is not at the vehicle to see what’s wrong, and you can only go through a troubleshooting list while you’re at the vehicle or review the scan to see where the diagnostic trouble code (DTC) is causing an issue. I wish there was a magic service that you could call and be able to take care of all your needs; I just haven’t seen one yet.

Summary

There is so much to consider when contemplating adding calibrations and/or diagnostics to your shop. Equipment, space, training, diagnostic training and experience are only a few items to look at. You really need to weigh the ROI and how long it will take to see returns to your shop. It may be a dream situation and come quickly. It may not. It’s your shop; pick your equipment and needs wisely. Ask the right questions on vehicle coverage and support. I wish you the best, as there are a lot of companies out there making equipment.

It’s amazing to me how the repair industry adapts and learns. It’s even more amazing to see how fast it occurs compared to years past. Shop owners and technicians have proven to be adaptable to changes that are tough to follow as well as keep up with. I meet owners all the time who impress me with the way they embrace change. That makes me pretty proud of all of you who are doing the right thing in repairing vehicles. I just want to say thank you to all who put that effort into their business and their team.