Vehicle manufacturers build vehicles. They put years of research and design into every vehicle and model they sell. The manufacturers stake their brand and personal reputation on that platform rolling off the assembly line. They believe that through research, design and testing, their complex vehicle designs will perform as intended for the owners and their families while driving down the road to the unfortunate incident of a crash. They research and assemble the vehicle to be durable, sustainable, safe and survivable throughout its entire expected life.

The vehicle manufacturers ask that maintenance be performed to maintain the functionality of the drive train, body and electronics. Vehicle manufacturers also ask that if something does happen to the vehicle — whether it’s a part failure, system failure, damage occurring from everyday life or a crash — that it be repaired so that all the research, engineering and design will still function correctly after repairs. Their service information may contain information on measurements, tolerances and specifics needed to repair the vehicle correctly.

OEM Repair Procedures

To help with the repair, automakers establish procedures to follow. The procedures are things that must be done to maintain all that engineering — taking into consideration what mechanical and auto body shops are capable of, given the technology and technician skills available.

I’ll sometimes use aluminum body structure and panels as an example. The vehicle manufacturer pushes the industry to buy equipment, and then practices evolve to meet their designs. The evolution of the automobile has always dictated the evolution of the repair industry too. Equipment manufacturers answer the call and provide equipment for the industry to meet the OEM procedures. Also, training is done to meet the OEM procedures. The reality is that the OEM procedures are the foundation of our industry as far as how to repair all aspects of any vehicle.

OEM procedures are the foundation of our industry when it comes to repairing all aspects of any vehicle.

Procedures and requirements to complete repairs are not always universal between vehicle manufacturers or even between models of vehicle from the same vehicle manufacturer. To add to the complexity, vehicle manufacturers are learning too. Once the vehicles are on the road and challenges are noted, vehicle manufacturers may update or change a procedure.

This is where assumptions become so dangerous to the repair industry. A shop or technician may assume that, since it was correct on the vehicle he or she worked on three months ago, it will still be correct on the vehicle he or she is working on today. In the collision and mechanical worlds, it may not change that quickly, but in the world of electronics, it changes very frequently.

Not researching OEM procedures to validate that you’re correctly repairing the vehicle can create headaches and complexities for any shop. In electronics, it could be the difference between successfully or unsuccessfully programming or initiating a module. In mechanical shops, it could be a vehicle not starting or coming back with a repeated issue. For body shops, not following OE procedures may lead to failures on seams, welds or longevity of the repair, ultimately leading to warranty issues. All this may lead to rework and its added costs as well as customer satisfaction issues and damage to your shop’s reputation. In safety systems, such as occupant classification and advanced driver-assistance systems (ADAS) or automatic braking systems (ABS), it could be catastrophic for the vehicle owner and shop.

Navigating OEM Info

Where you get your OE information is as important as looking at the procedure in your hands. If you’re using outside sources to get the information, you need to validate that the information is current because, as I mentioned before, information changes quickly. Always be sure to look at current position statements and technical service bulletins (TSBs) related to the vehicle and work you’ll be performing. Using outside sources, such as ALLDATA and I-CAR, has huge advantages in that it greatly reduces the time needed to look up the procedures.

One drawback is the amount of information that you do not receive. You may have asked for or looked up the procedure, but did you also see the prerequisites that should be completed prior to the process you want to perform? Learning about aiming a radar and the procedure to do so before putting the bumper cover on is a pretty important step in the process on some vehicles. If you receive the instructions in a file, many times you can see there are hyperlinks leading to more information, but they’re not active for you. Not being able to access those hyperlinks may prevent you from receiving information you need to complete the repairs correctly.

Researching through the OE service information, you’ll find items and procedures you did not know existed. You start to realize how many assumptions may be incorrect as they compare to the OE process. I have a friend who regularly scours the sites for information, and he comments almost every day, “Hey, did you know this manufacturer wants this repaired this way?” Which is where I find myself assuming so much about repair procedures and realizing I have been seriously wrong in some of my thoughts on many repairs.

Accessing an OE Website

When using the OE websites for a day, three days or longer subscriptions, it can be confusing to find the information you need. Research takes time, as you’ll need to locate where the information is through categories, subsections and hyperlinks on the website. What makes it even tougher is there is no standardization from vehicle manufacturer to manufacturer.

A good example would be looking for ADAS components for forward camera features, such as lane keep, forward collision warning or radars for blind spot, in the “Safety and Security” section of the GM site. Because the 360-surround view uses a monitor in the dash, the information needed is actually found in the “Driver Information and Entertainment” section. On Honda’s website, all of this would be in one section. Once you’ve learned how and where to navigate, the site becomes priceless for the information you’ll gain.

While navigating all the categories or subsections, be sure to check the hyperlinks when offered more information, as these will be active for you. You may find what you were looking for not stated in the procedure you thought it might be under. An example would be a shim procedure for the Eyesight camera on Subaru vehicles after a roof replacement.

These little bunny trails from the procedure you’re viewing can lead you to a plethora of other information you need to complete repairs. One thing to note is that the advantage to accessing OE information on the OE websites is that the info is current. This is a big advantage to outside services providing the information; it all depends on the providers’ refresh rate on information.

Industry ADAS Evolution

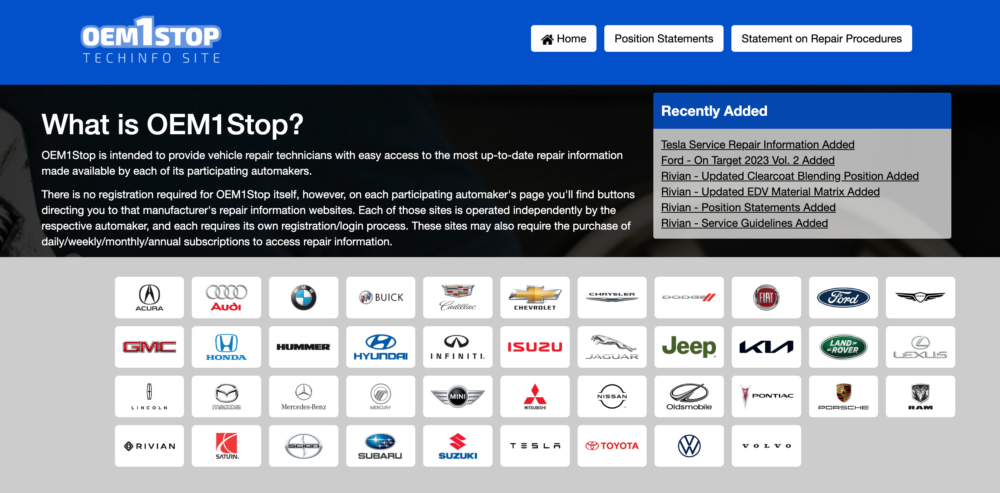

Finding the websites is easy, since there are sites such as OEM1Stop, I-CAR and many others. There are also websites that have vehicle manufacturer position statements and service info that are easily located and downloaded.

I must admit, this type of research gathering is changing and evolving. Artificial intelligence programs now being offered that access calibration information are also adding diagnostic solutions and, in some cases, body repair procedures directly into estimating software, taking the research labor from you and allowing you or your staff to do other tasks. New products are appearing every day, such as IdentiScan by CalPro ADAS solutions and Repairify (Insights AI). The AI solutions use information from the OE to scan a vehicle or an estimate to provide the OE requirements for repairs, giving you peace of mind among so many other advantages for your shop.

Why Follow OEM Procedures?

I am not saying the OE procedures are perfect. I am saying they’re the baseline of where we must repair any aspect of the vehicle. Following these procedures gives the industry a place and a bar that must be met to repair the vehicle correctly to their engineering design. We may not know why the OEM designed the process that way, but it did so for a reason. And I am not an engineer who has tested and documented that my way of repairing the vehicle, different from the OE procedure, is correct. I am a repair professional who is given a procedure that must be followed to maintain operational functionality of a complex, engineered vehicle. It does not matter if it’s a body repair procedure, such as welding or adding the correct corrosion protection or calibrating a parking sensor or programming a blind spot monitoring (BSM) module. The OE procedures are there to correctly repair, test and validate all procedures are done for the vehicle owner and his or her family.

I am not going to go into the OE procedures as to OE part vs. aftermarket part use as that is an age-old argument that will most likely be resolved in somebody else’s lifetime.

Deviating from these procedures and requirements can be dangerous for many reasons. We’re in a different world today than we were yesterday. Money changes everything. I see so many people who do not want to take responsibility for their actions, since everyone is afraid of being the subject of litigation or wishes to bring litigation because he or she does not want to be at-fault or responsible for his or her actions.

There also seems to be a faction of society that will take advantage of any opportunity placed in front of them. A vehicle that has been repaired in a shop and is involved in a collision may be subject to serious analysis if somebody claims his or her vehicle was not operating correctly and failed to recognize the danger and assist as designed. History has proven that not following OE procedures during collision repairs can become subject to litigation. That’s the extreme case scenario, but warranties and customer satisfaction seem to be a focus in the industry today as vehicles become more complex. Following OE procedures will become more important to your success than ever before.