Today’s vehicles incorporate many different types of fuel-saving materials such as lightweight alloys and exotic plastics. It’s a huge undertaking to be aware of these materials, identify them, keep pace with changes in them and learn how to handle them. This is especially true if the manufacturer’s repair recommendations are not available to you or your team.

Throughout the day, collision repairers bring such repair recommendations, which they’ve found to be helpful, to my attention. This article deals with Mazda’s bumper repair recommendations and service procedures for the Mazda 3 and 6 Series vehicles.

Service Procedure

Always refer to ALLDATA Collision for safety procedures, identification of material types, recommended refinish materials and removal and installation procedures. Always refer to Mazda for questions relating to applicable or non-applicable warranty repair information.

CAUTION: Read and follow all of the instructions from the manufacturer’s line of painting materials, equipment and protective gear.

Repairable Range

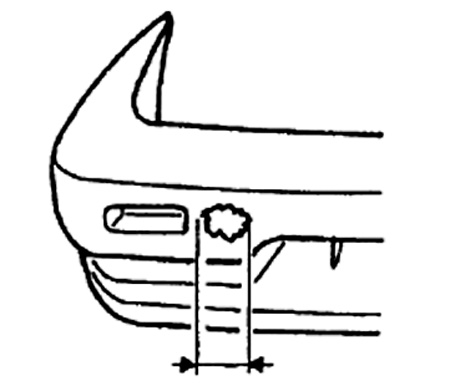

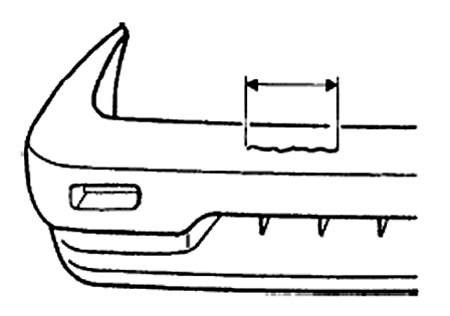

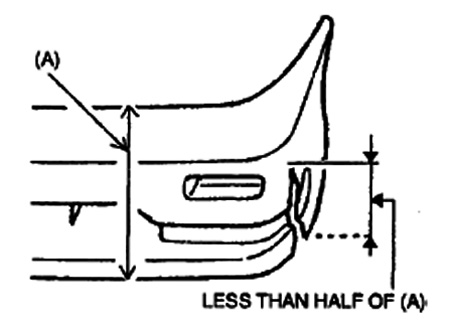

The three types of damaged bumpers shown below (Figures 1, 2 and 3) are considered repairable. Although a bumper that has more damage than this could also be repaired, it should be replaced with a new one because such repair would detract from its looks and quality. In addition, such repair isn’t considered reasonable in terms of work time.

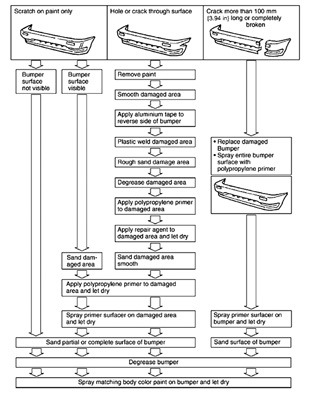

Please refer to the specific Mazda bumper repair procedures (Table 1 above) for polypropylene bumpers.

© 2008 ALLDATA LLC. All rights reserved. All technical information, images and specifications are from ALLDATA Collision. ALLDATA is a registered trademark and ALLDATA Collision is a mark of ALLDATA LLC. All other marks are the property of their respective holders. Mazda, Mazda 3 and Mazda 6 are registered trademarks of the Mazda Motor Corporation and are being used solely for reference and application purposes.

Dan Espersen is the ALLDATA Collision Program Manager. He’s I-Car Platinum Certified and a Gold Pin Member of the Collision Industry Conference (CIC), and holds an AA Degree in Automotive Technology. He has 15 years of experience in the collision industry and 17 years of experience in the automotive industry.